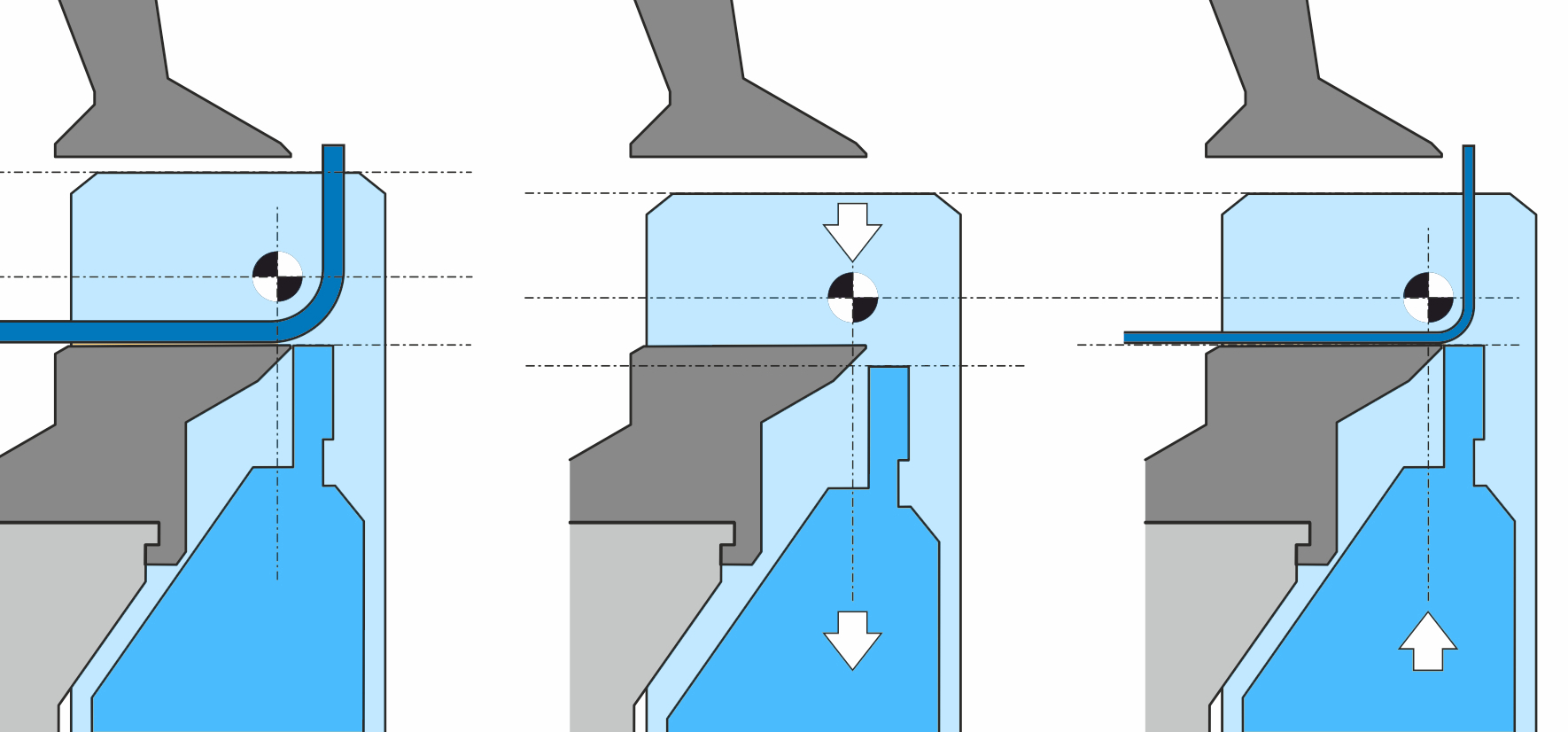

UpDown bending technology

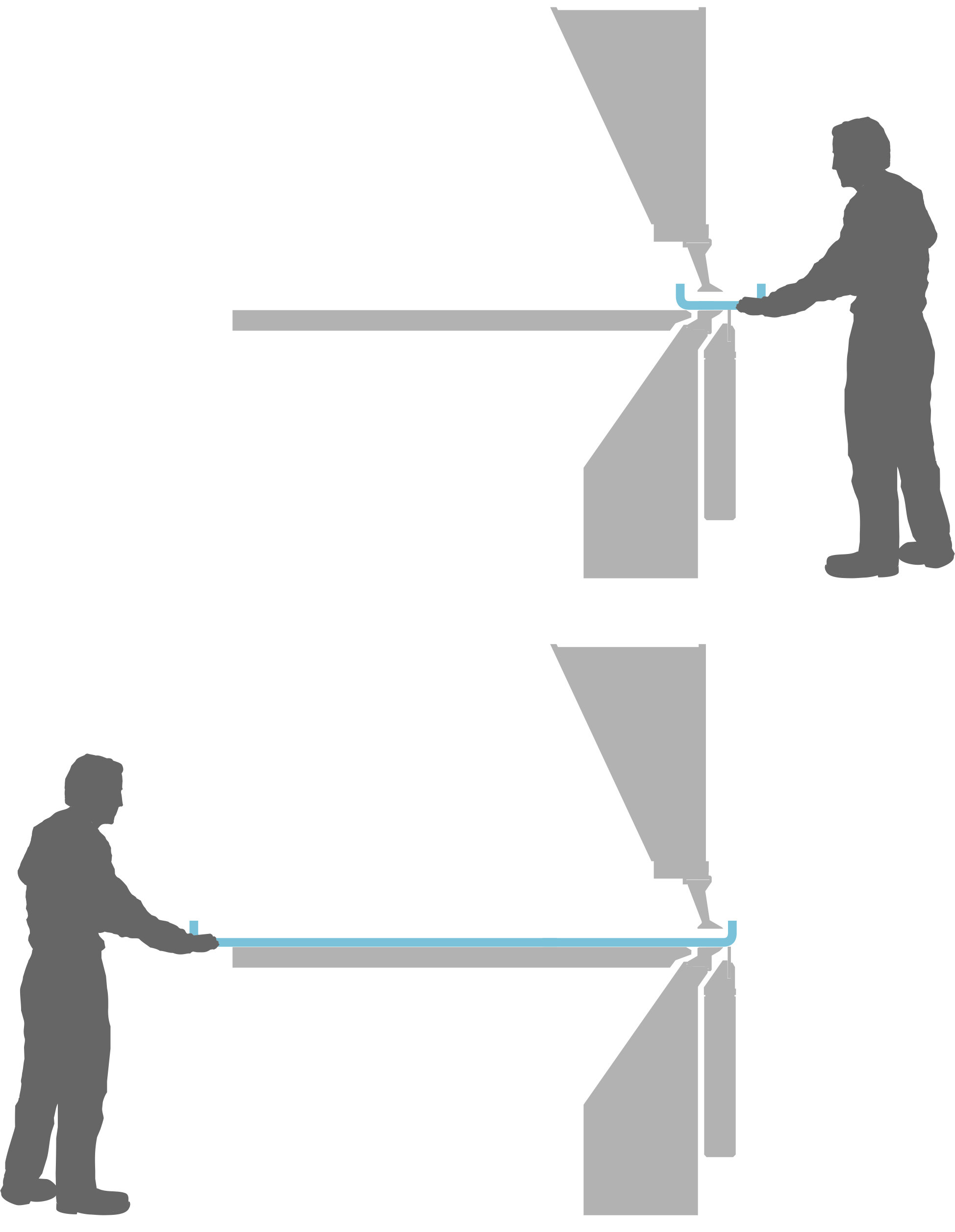

The XLTbend can be operated from the front and from the rear. With the new and double-monitoring safety system, even a front operation with UpDown bending technology is possible.

- No material flipping required

- Program controlled folding beam pendulum movement (zero setup time)

- Passing pre-bent flanges (150 mm folding beam stroke)

- Deep folding beam (perfect bending accuracy)

- Quick and easy operation. Short cycle times.

- Automatic folding sequence per station and part side

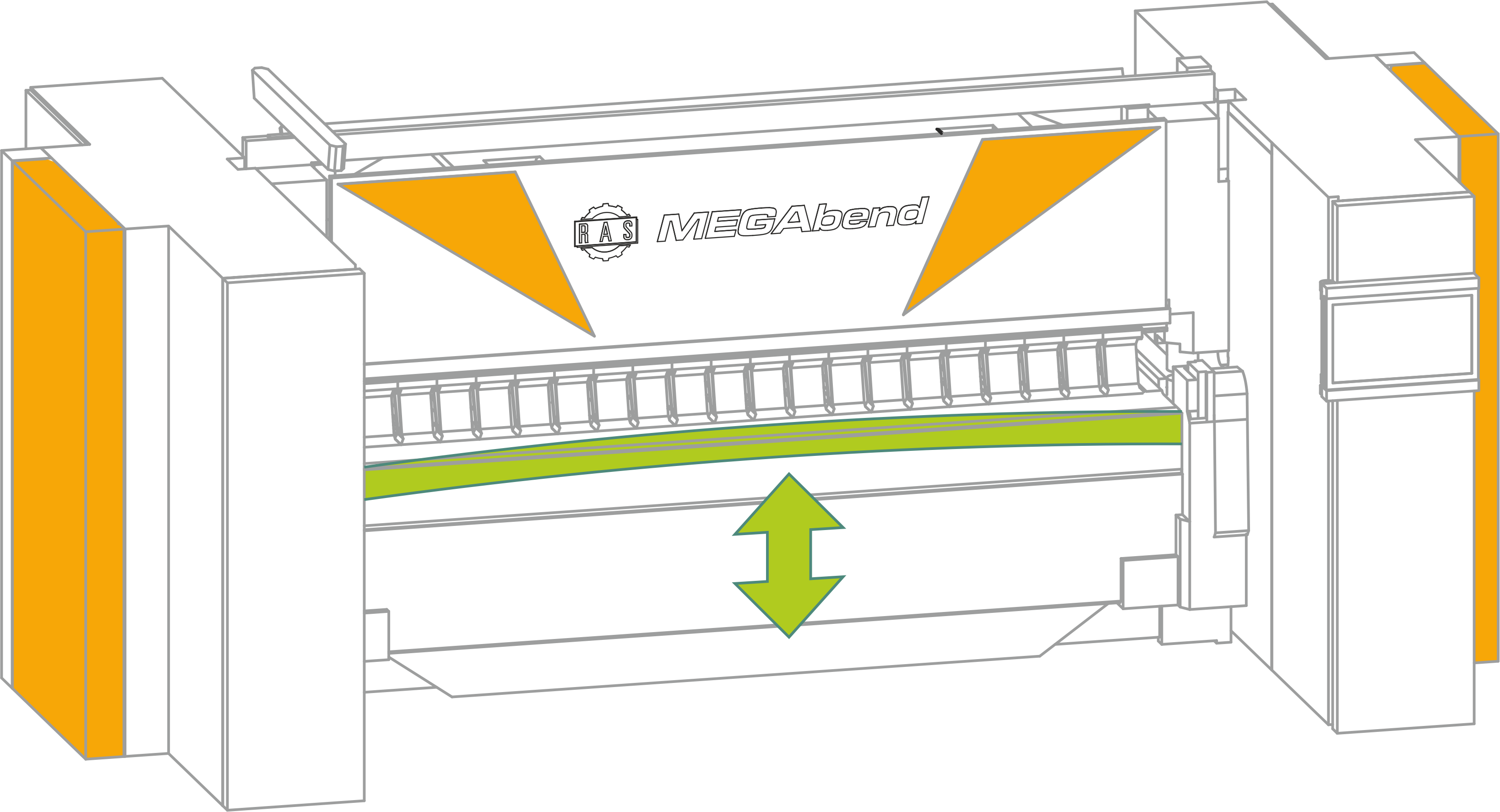

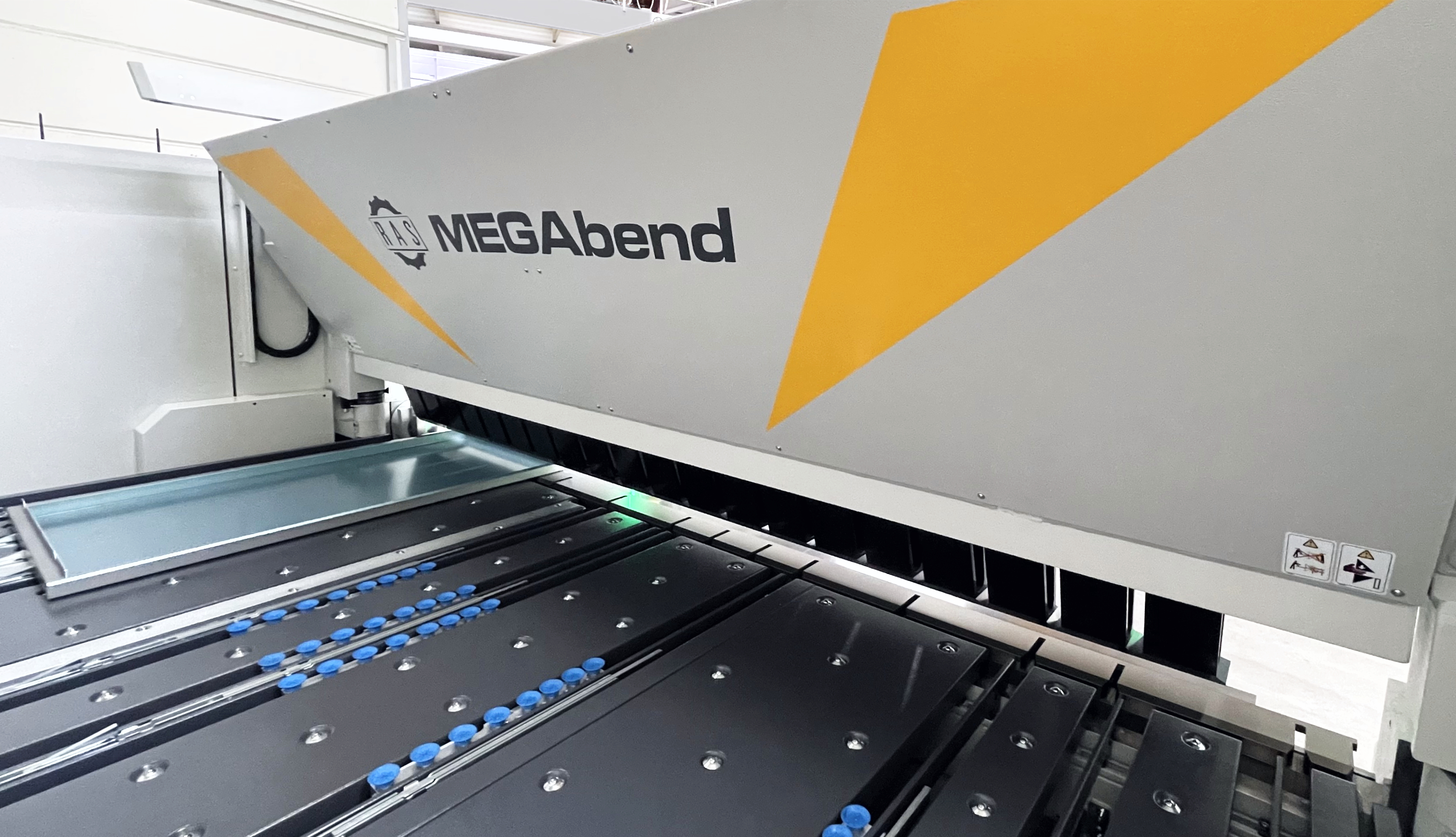

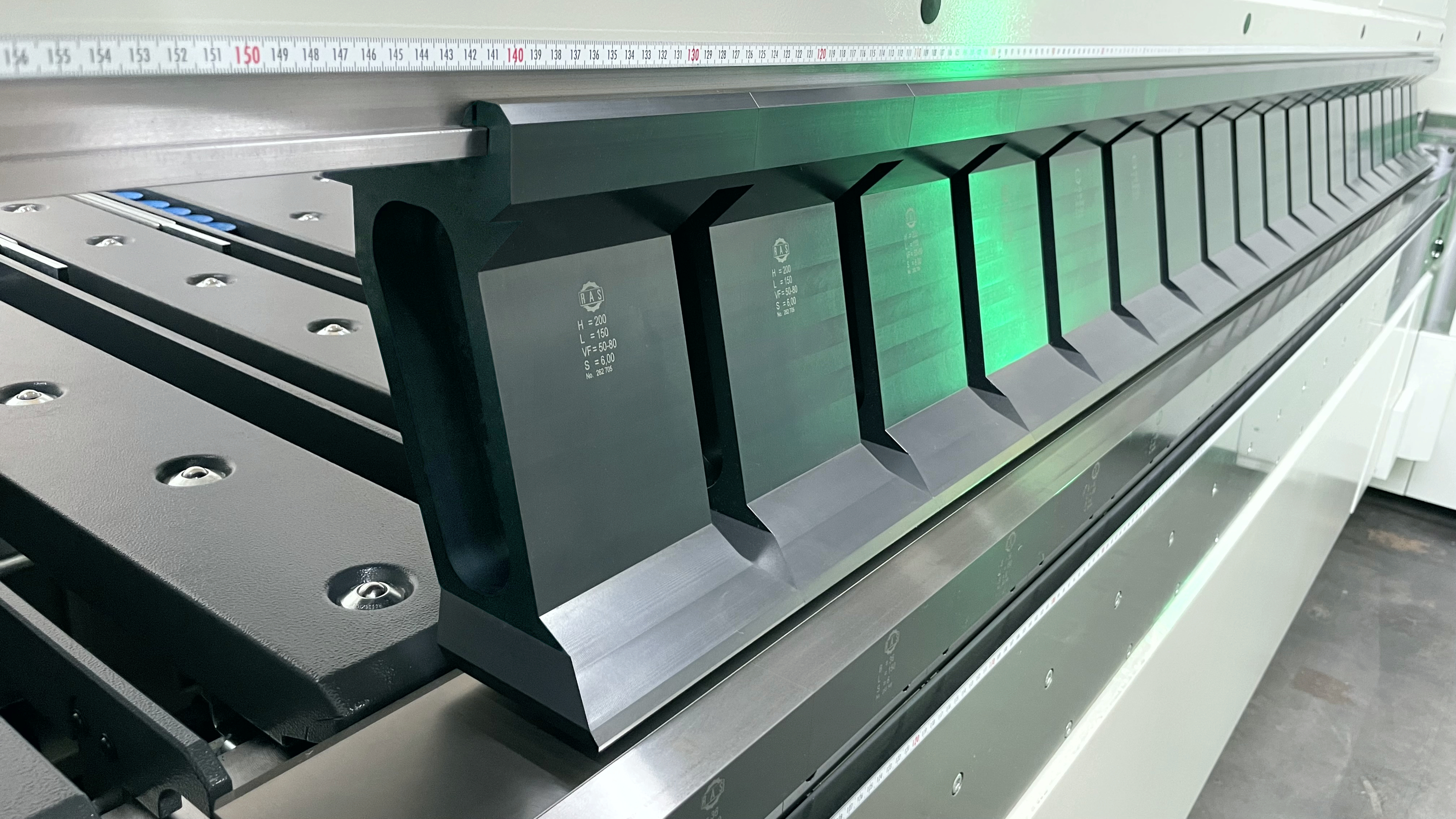

Revolutionary folding beam design with intelligent crowning system

The folding beam is a true power component of the machine. Its extremely rigid design allows only very low deflection. The intelligent crowning system automatically optimizes the folding beam and automatically compensates for deflections caused by the bending forces. This enables the MEGAbend to achieve straight bends with thin or thick sheets, all material types, long or short flanges, when bending in the center of the machine or on the side. Fast movements ensure high productivity. Automatic adjustment to sheet thickness and bending radius increases productivity and flexibility when bending small batches.

- Minimal deflection of the folding beam

- Straight bends due to the intelligent crowning system

- Folding beam can be used as a stop for inclined parts

- No setting times due to automatic adjustment to thickness and bending radius

- No downtime for material change

- Fast movement: short cycle times

- SpeedOptimizer increases speed by releasing the part when the folding beam moves to its home position.

- Automatic clamping of segmented folding beam tools

- Gentle forming of coated materials

- Servo motors and absolute encoders: fast working, no calibration

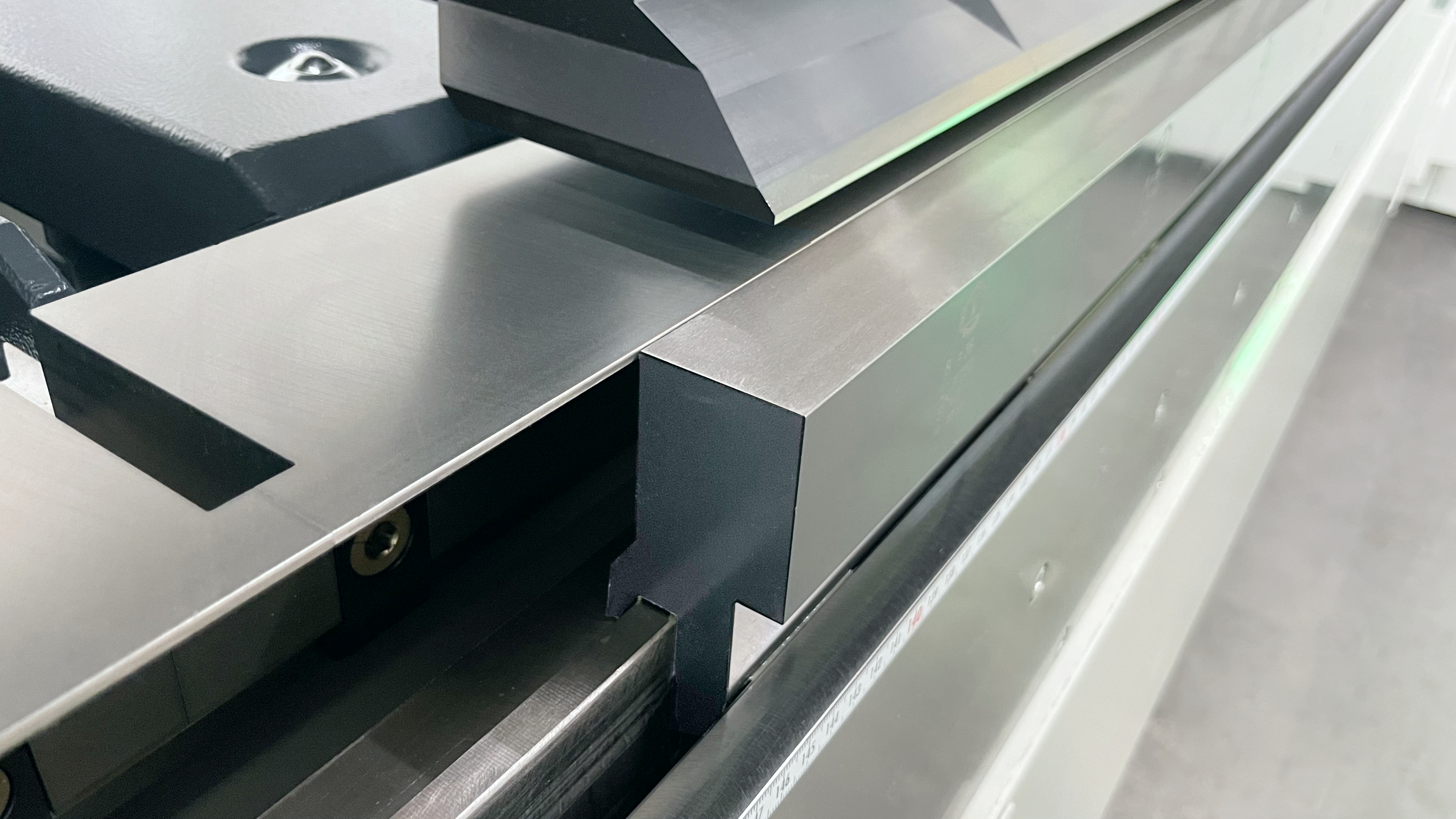

Rigid upper beam geometry

- Extremely rigid box shape upper beam projecting steeply upwards (high bending quality)

- Large clearance in front of the upper stringer

- Large clearance behind the upper beam (rear visibility and access)

- Automatic tool clamping (fast set-up)

- 3-axis servo drive (fast travel, high clamping forces)

- PowerBooster builds up to 120 tons of clamping force (secure holding of thick sheets, perfect hemming)

- Encapsulated spindle drive in oil bath (low maintenance)

- Servo-regulated motors right and left (ball screws)

- Programmable clamping position (hemming)

- Programmable opening height (fast operation)

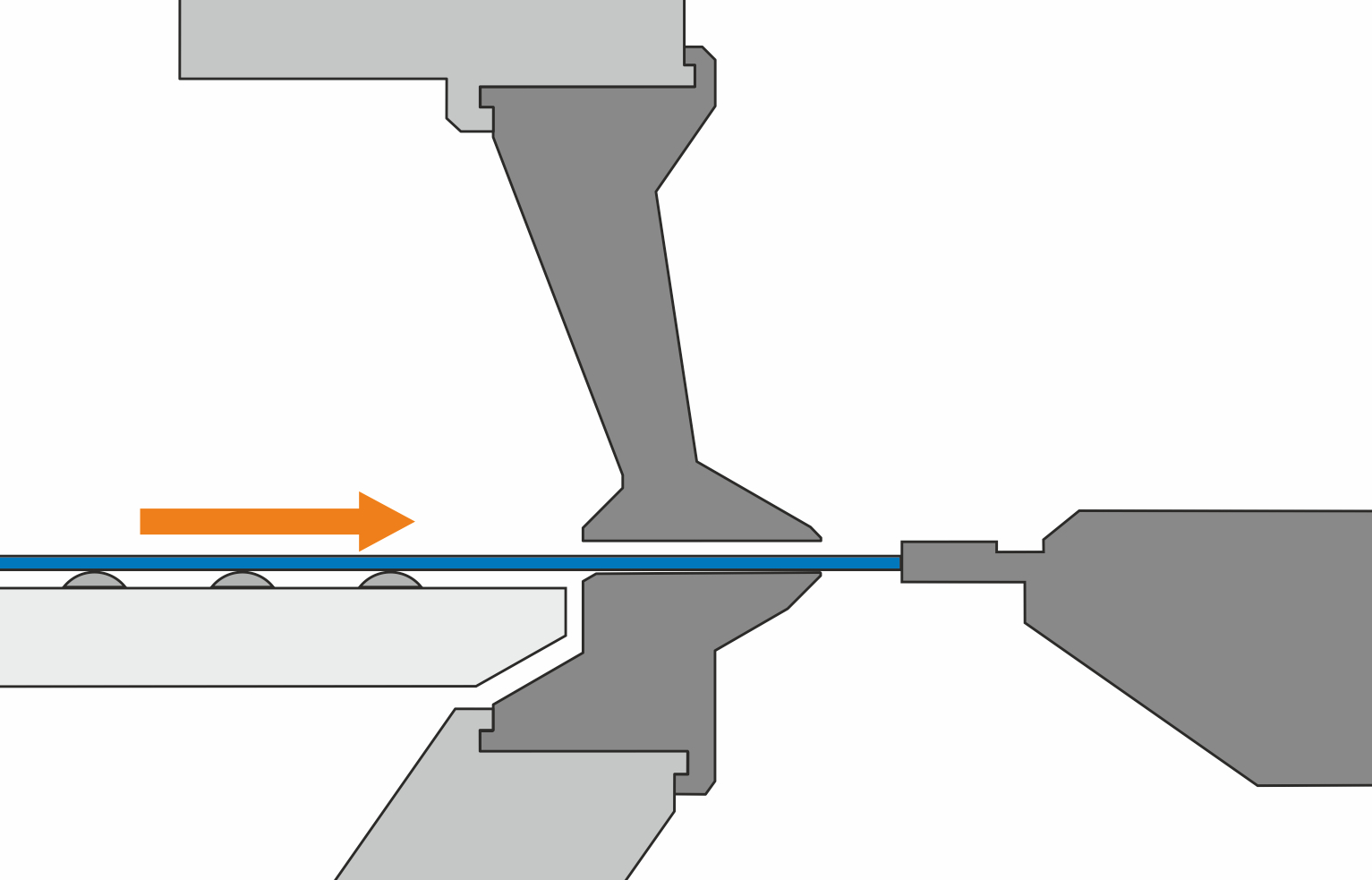

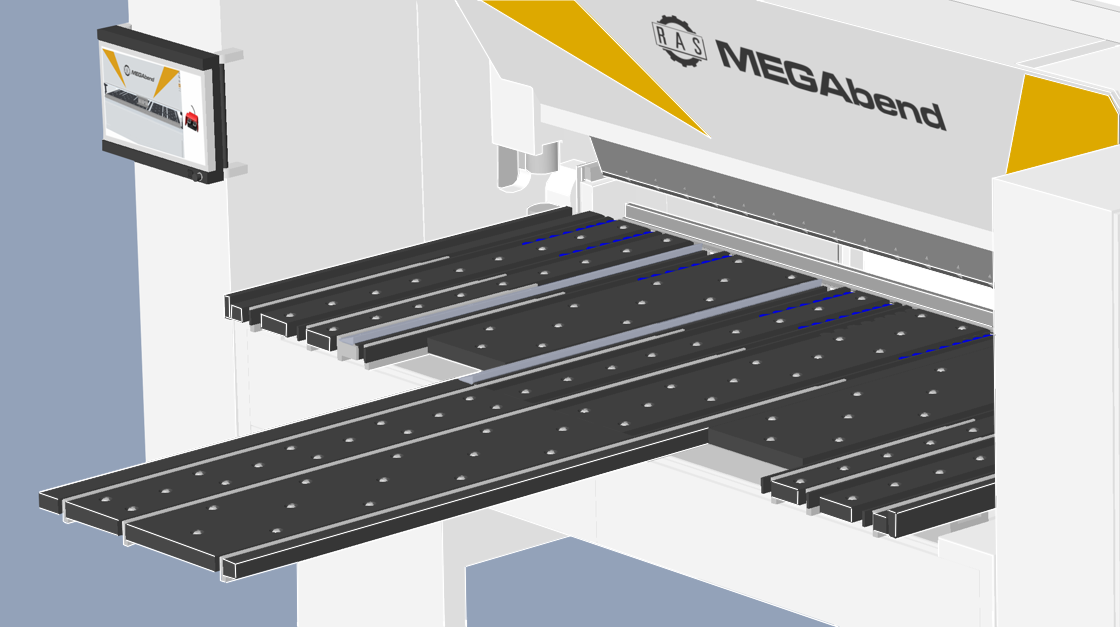

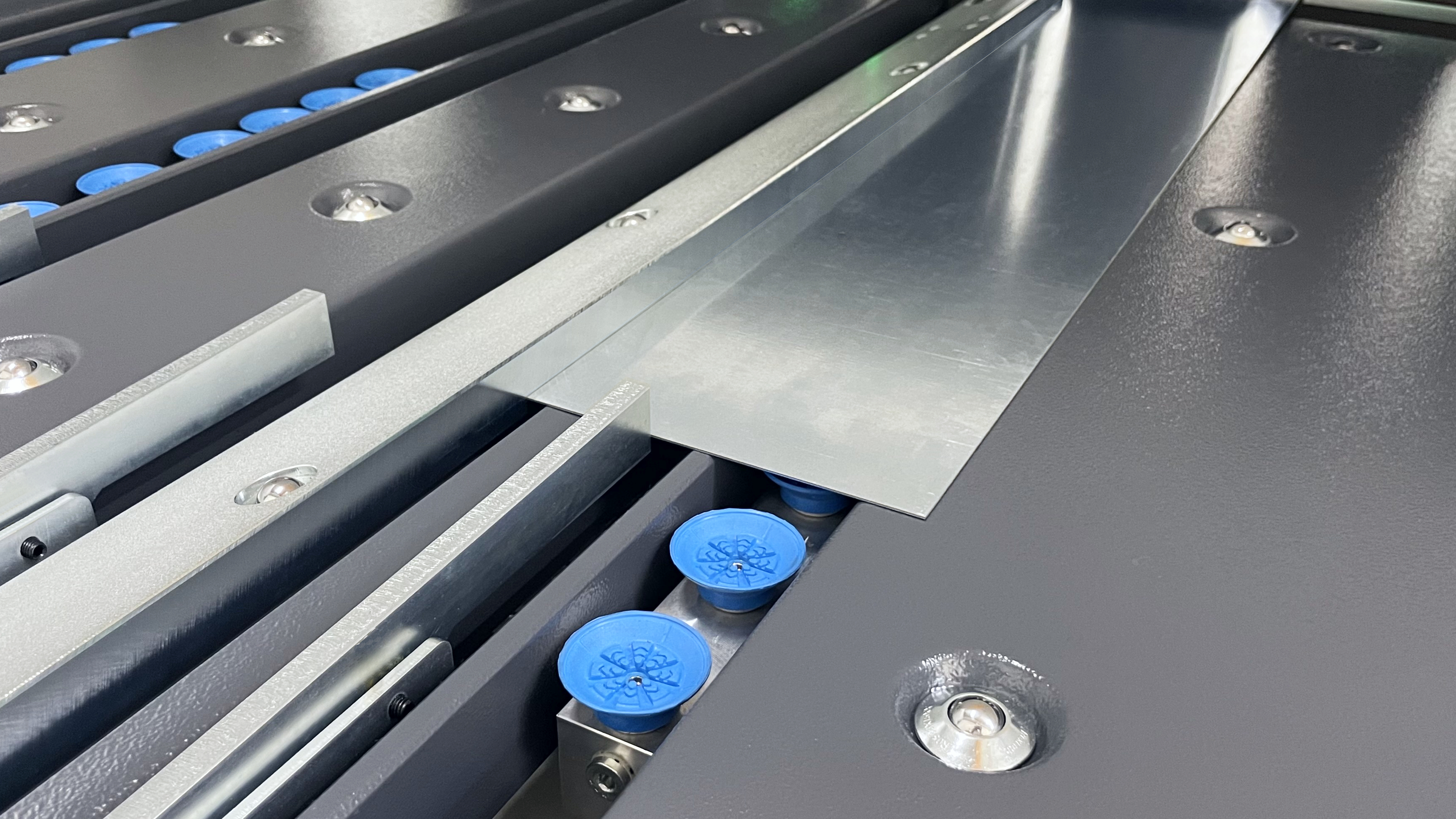

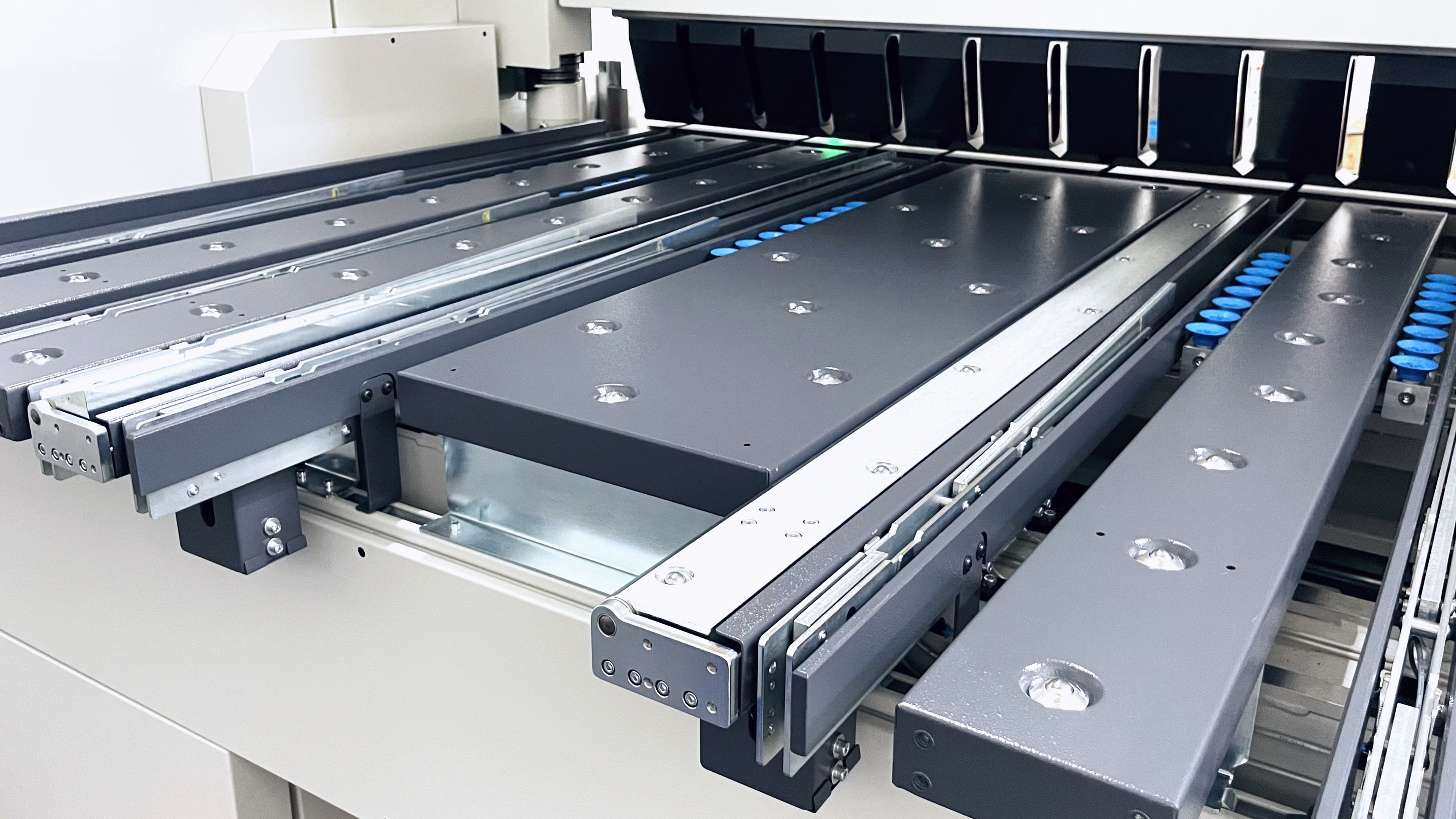

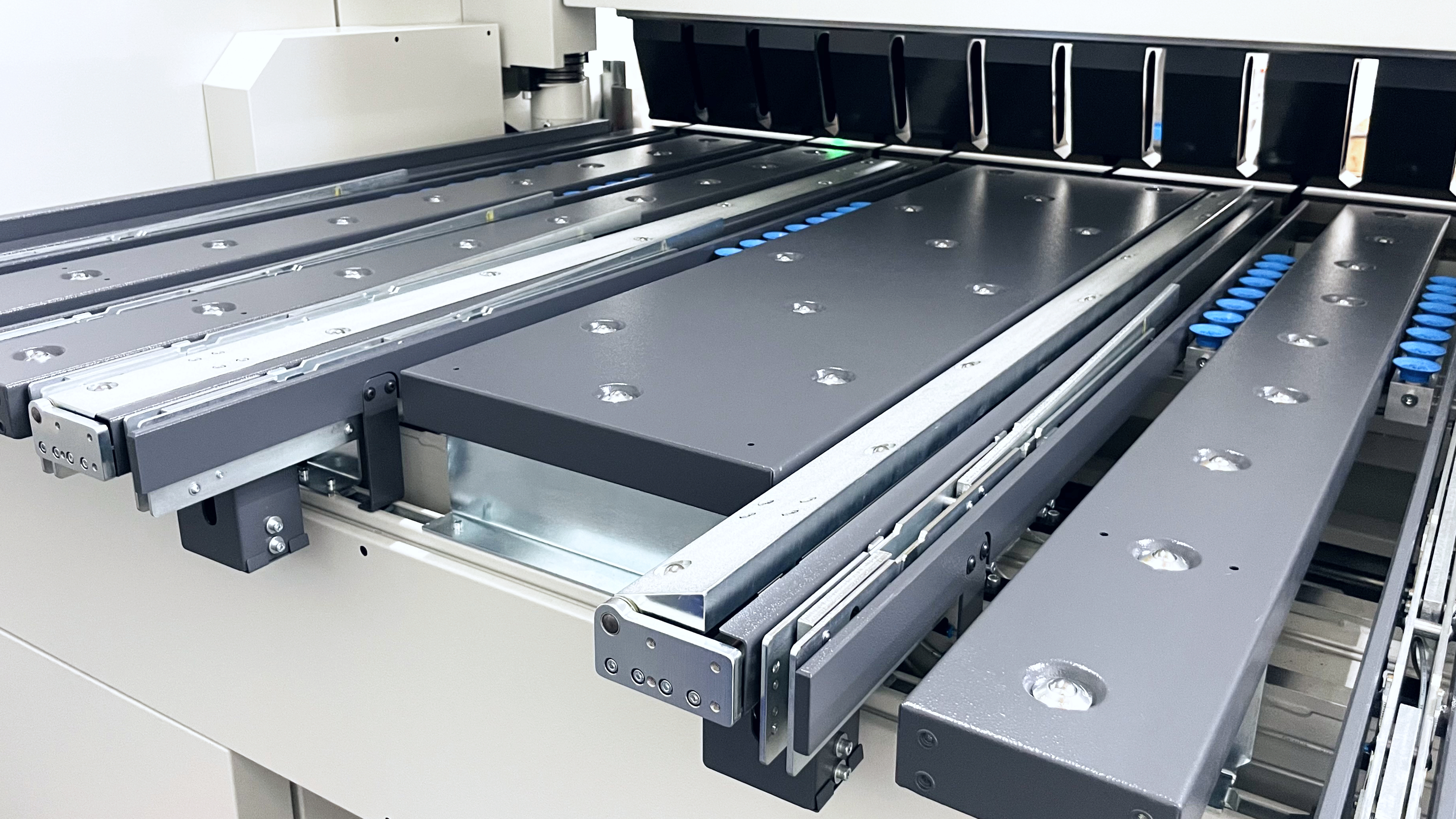

Stop fingers and suction bars

With the RAS hybrid gauging system, the stop fingers position the workpiece on the bending line. At the same time, suction bars hold the part against the stop fingers during the bending process so that subsequent bends can be made without operator intervention. The extended T-shape gauging system provides maximum support even for large parts.

- Automatic bending sequence per station and part side

- Hybrid gauging system eliminates gauging mistakes (precise bent parts)

- Finger rows separately activated (fast positioning)

- Suction bars hold the sheet metal part during the bending sequence. Each bar with 8 suction cups moving as an independent axis.

- Operation from the gauging system side: the suction bars pull the finished part to the rear for convenient unloading (requested: use of SnapTools for boxes with C flanges)

- Automatic programming of the suction bar movements

- Rigid stop fingers (long lasting accuracy)

- Each individual finger in the rectangular area of the gauging system can be manually locked (coil material with wavy outer edge)

- Two pop-up squaring arms (alignment of long and narrow parts)

- Folding beam can be used as a stop (max stroke 150 mm)

- Table surface 3200 mm wide (T-extension 940 mm wide)

- Two shorter sheet support tables for best accessibility

- Sheet supports powder coated with ball rollers

- Stop dimension 20-3250 mm

- Light control indicates working condition of the machine

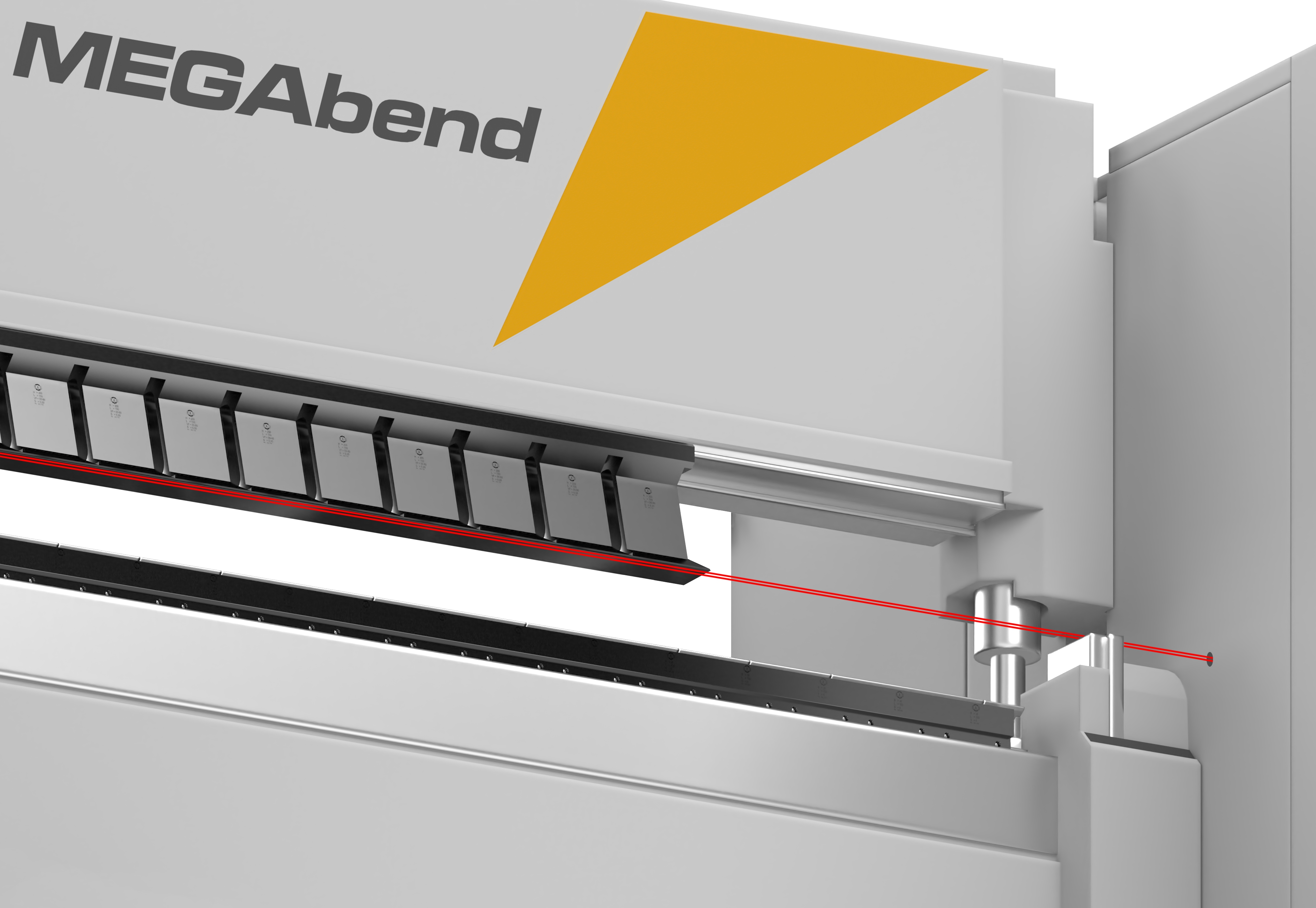

ViN (Virtual Navigator)

The ViN (Virtual Navigator) shows the operator the exact part loading position with an intelligent laser beam. The software calculates the position of the visible edge of the blank in accordance with the actual tool setup. When working from the gauging system, smaller parts can be easily loaded at the end of the gauging table (support function).

- Laser beam shows the exact part loading position

- ViN moves along the working length under program control

- Laser shows loading position on folding beam and gauging system side

- Loading position matches to the tool set-up (also with a multi-station setup)

- Quick and precise part loading

Universal tooling system

RAS has created a maximum free space in front of and behind the upper beam tools of the MEGAbend. With tools up to 400 mm tall, the MEGAbendis ready for all applications. A variety of folding beam tool are available for the smallest Z dimensions or thicker materials. Nevertheless, many users just need a single set of tools for their entire production range.

- Quick set-up, due to handy tool segments

- Automatic tool clamping

- Front-free and rear-free tool geometries

- Folding beam tool widths from 14 to 36 mm

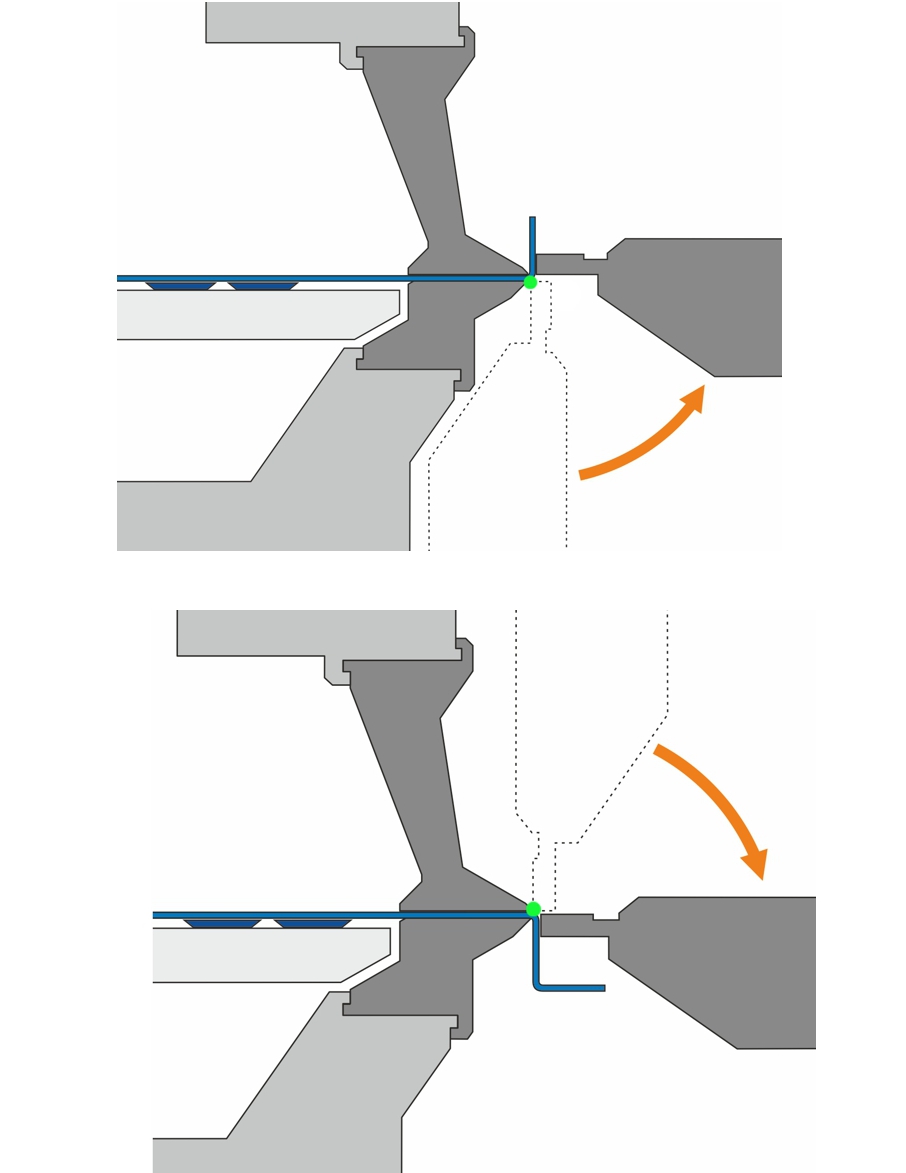

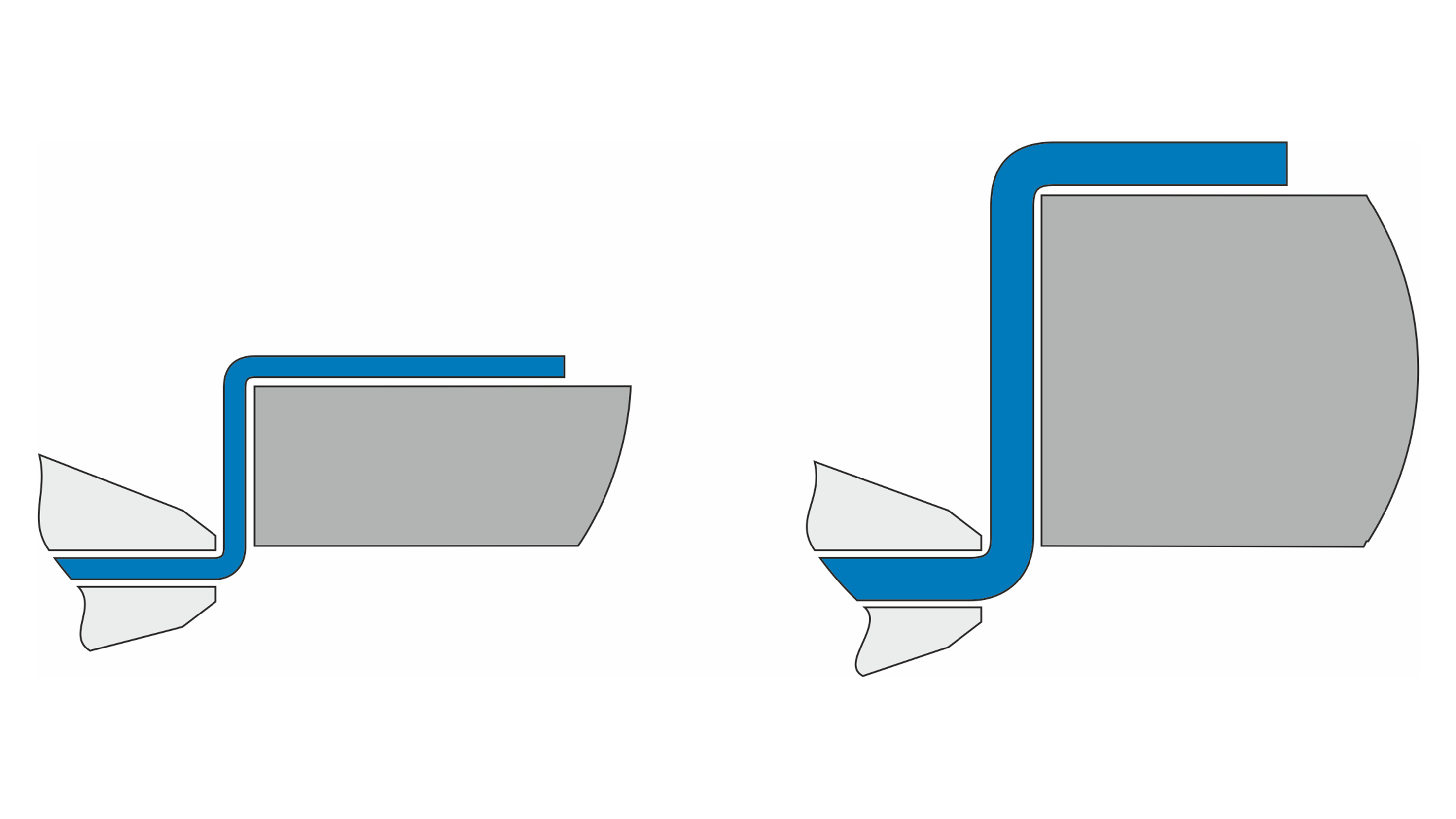

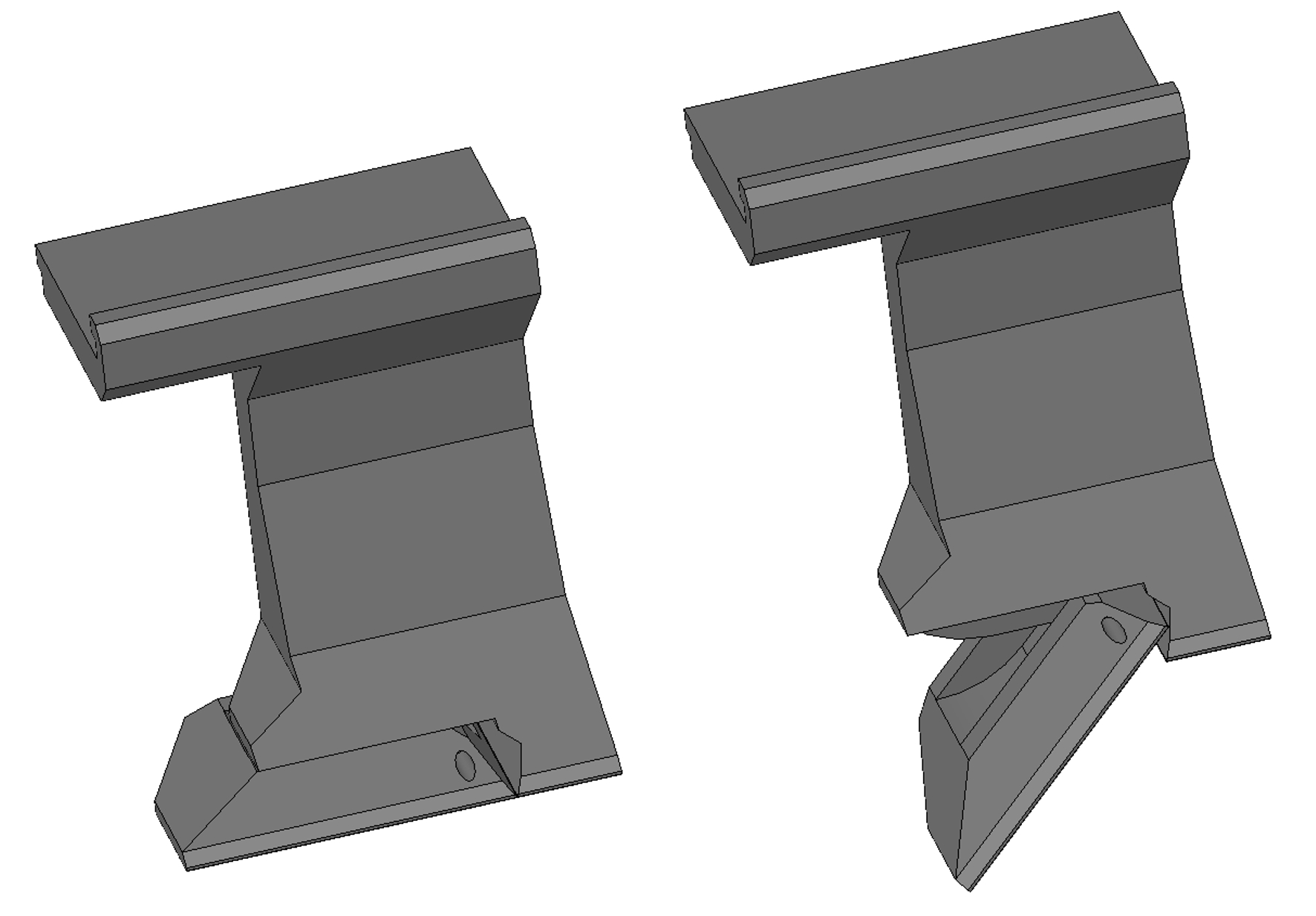

SnapTool corner tools

The SnapTool corner tools with a hinged foot automatically retract from parts with side flanges. The hinged foot moves down when the upper beam opens and snaps back into the working position as soon as the tool has moved out of the bent part.

- Automatic bending sequences: A manual rotation of the bent parts at the end of the bending cycle is not necessary

- Working from the gauging system: The bent part can be returned to the operator using the support function

- Side free space in the hinged area of the SnapTool up to 55 mm

- Designed for the same sheet thickness as the other tools of the tool set

- Software calculates the SnapTool positions