Effortless, precise bending

of thick sheets

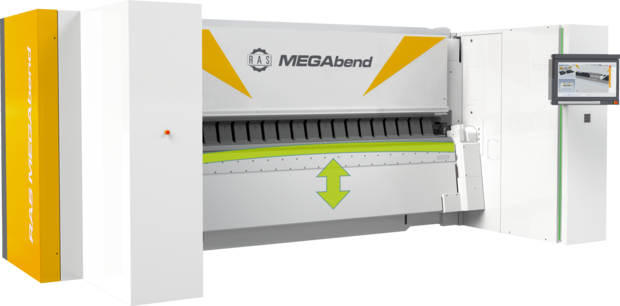

MEGAbend Bending centers

RAS MEGAbend: UpDown metal folding up to...

RAS MEGAbend cassette bending

MEGAbend with MetalLift

MEGAbend … extra powerful

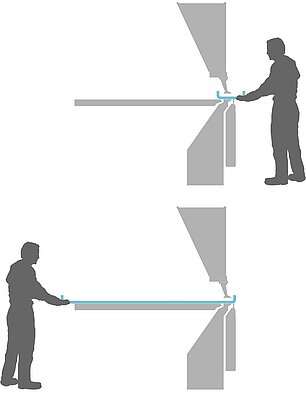

The MEGAbend metal folding system proves the precision of updown bending on thick and thin materials. Large-size parts, difficult and labor-intensive for press brakes, are ideal for the MEGAbend. The Bendex graphics software programs the bending sequences automatically. The stop system with fingers and suction bars allows automatic sequential bends. The ViN laser shows the operator the blank loading position. The tools offer plenty of free space for unique bending geometries.

- UpDown folding of up to 6 mm mild steel

- A single person can even bend large and heavy components

- ViN (Virtual Navigator) shows the loading position with a laser beam

- Automatic sequential bends without operator intervention

- SnapTools: automatic dipping from lateral legs

- Two automatic pop-up squaring arms

- Import of CAD file data (STEP, geo, dxf, dwg, etc)

- Automatic programming of the bending sequences

- PowerBooster for extreme upper beam clamping forces

- Intelligent folding beam crowning system

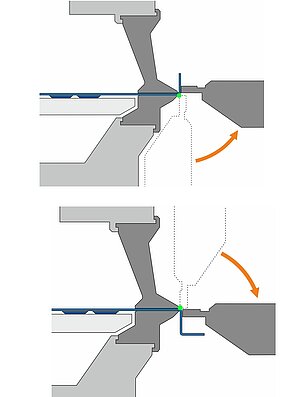

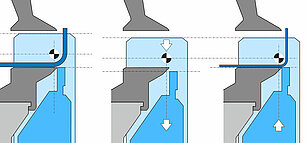

UpDown bending technology

The XLTbend can be operated from the front and from the rear. With the new and double-monitoring safety system, even a front operation with UpDown bending technology is possible.

- No material flipping required

- Program controlled folding beam pendulum movement (zero setup time)

- Passing pre-bent flanges (150 mm folding beam stroke)

- Deep folding beam (perfect bending accuracy)

- Quick and easy operation. Short cycle times.

- Automatic folding sequence per station and part side

Revolutionary folding beam design with intelligent crowning system

The folding beam is a true power component of the machine. Its extremely rigid design allows only very low deflection. The intelligent crowning system automatically optimizes the folding beam and automatically compensates for deflections caused by the bending forces. This enables the MEGAbend to achieve straight bends with thin or thick sheets, all material types, long or short flanges, when bending in the center of the machine or on the side. Fast movements ensure high productivity. Automatic adjustment to sheet thickness and bending radius increases productivity and flexibility when bending small batches.

- Minimal deflection of the folding beam

- Straight bends due to the intelligent crowning system

- Folding beam can be used as a stop for inclined parts

- No setting times due to automatic adjustment to thickness and bending radius

- No downtime for material change

- Fast movement: short cycle times

- SpeedOptimizer increases speed by releasing the part when the folding beam moves to its home position.

- Automatic clamping of segmented folding beam tools

- Gentle forming of coated materials

- Servo motors and absolute encoders: fast working, no calibration

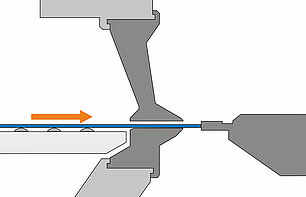

Rigid upper beam geometry

- Extremely rigid box shape upper beam projecting steeply upwards (high bending quality)

- Large clearance in front of the upper stringer

- Large clearance behind the upper beam (rear visibility and access)

- Automatic tool clamping (fast set-up)

- 3-axis servo drive (fast travel, high clamping forces)

- PowerBooster builds up to 120 tons of clamping force (secure holding of thick sheets, perfect hemming)

- Encapsulated spindle drive in oil bath (low maintenance)

- Servo-regulated motors right and left (ball screws)

- Programmable clamping position (hemming)

- Programmable opening height (fast operation)

|

RAS 76.30-2 |

RAS 76.40-2 |

|---|---|---|

| Working length | 3200 mm / 126" | 4060 mm / 160" |

| Material thickness max (400 N/mm² / 58,000 PSI) | 6.0 mm / 1/4" | 5.0 mm / 6 ga |

| Upper beam open height max | 850 mm / 33.5" | 850 mm / 33.5" |

| Box height max (four-sided) | 400 mm / 15.75" | 400 mm / 15.75" |

| Stop finger units in rectangular area | 10 (2 fingers each) | 12 (2 fingers each) |

| Stop finger units in T extension | 3 (3 fingers each) | 3 (4 fingers each) |

| Suction bars | 10 (8 suction cups each) | 12 (8 suction cups each) |

| Programming | automatic | automatisch |

| Machine dimensions (T gauging system) | 5400 x 5250 mm / 213" x 207" | 6260 x 6250 mm / 246" x 246" |

![[Translate to English:] Megabend mit MetalLift [Translate to English:] Megabend mit MetalLift](/fileadmin/_processed_/5/3/csm_Megabend-mit-MetalLift_5eafccc369.jpg)

![[Translate to English:] MEGAbend - Mega stark](/fileadmin/_processed_/d/4/csm_IMG_3614_8143b81766.jpg)