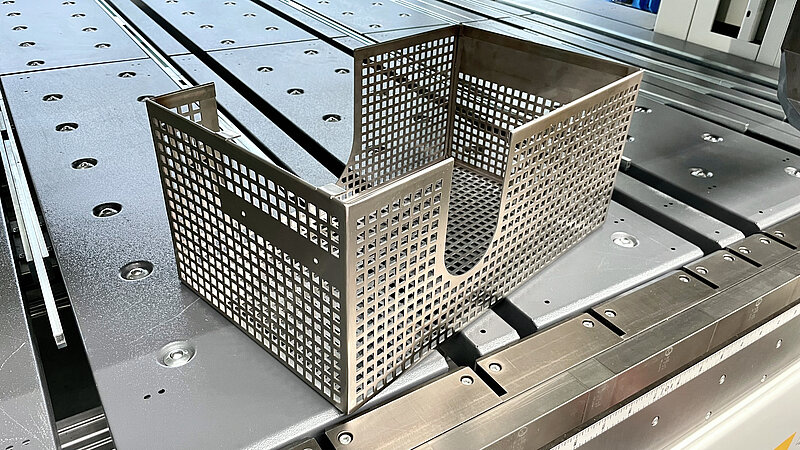

This video shows how the small parts bending center RAS MiniBendCenter bends a series of case components. The tool changer sets up the machine for the individual jobs and the manipulator positions and rotates the parts for each bend. The intelligent loading robot—no need to teach or program the robot—feeds the blanks from pallets with stacks of different blanks.

Eingesetzte Maschine:

MiniBendCenter-2

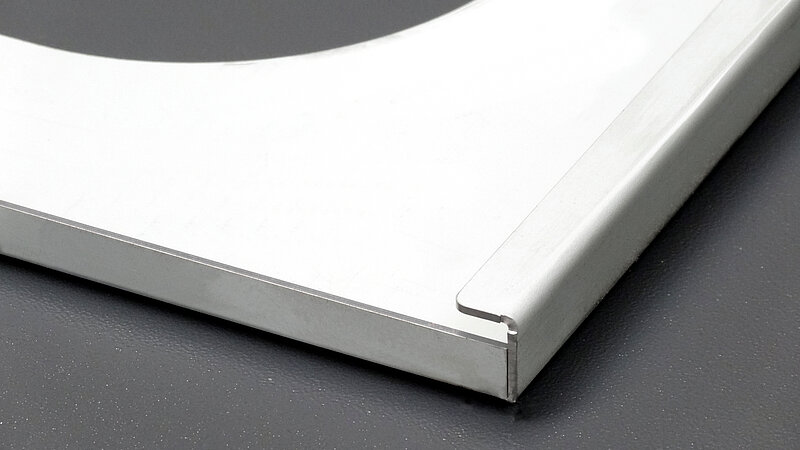

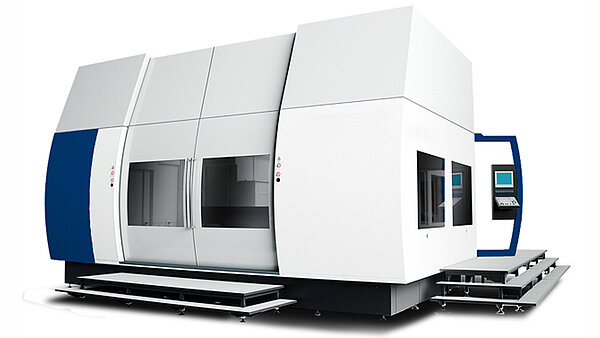

The RAS Multibend Center panel bender folds aluminum treadplates and creates tool boxes, as they are often used on pickup trucks. Due to the unique 3D bending technology the treadplate material surface will not be scratched during bending.

Eingesetzte Maschine:

Multibend-Center

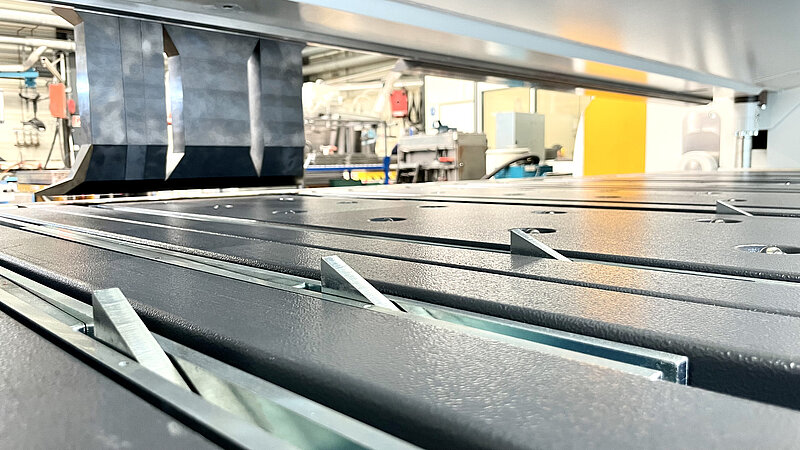

The RAS Multibend Center at the job shop Omega Blechbearbeitung AG bends machine covers and metal furniture, among other metal components. The video shows how the machine bends a belt guard for an agricultural vehicle. An intelligent loading robot loads the panel bending center with punched or laser cut blanks.

www.omega-blech.de

Eingesetzte Maschine:

Multibend-Center

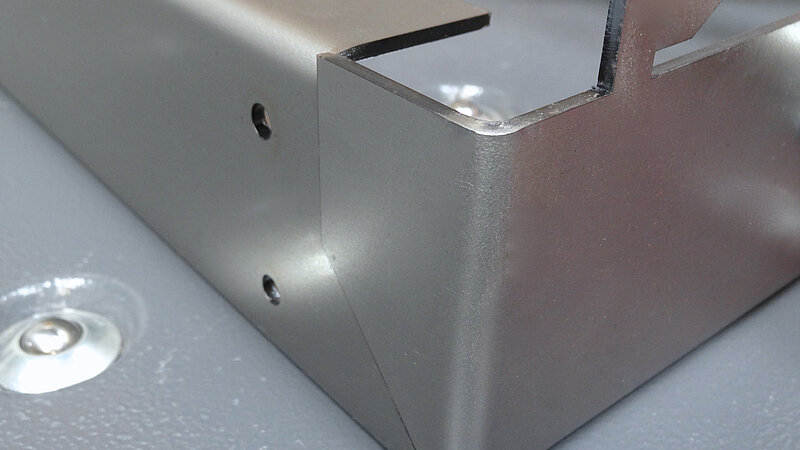

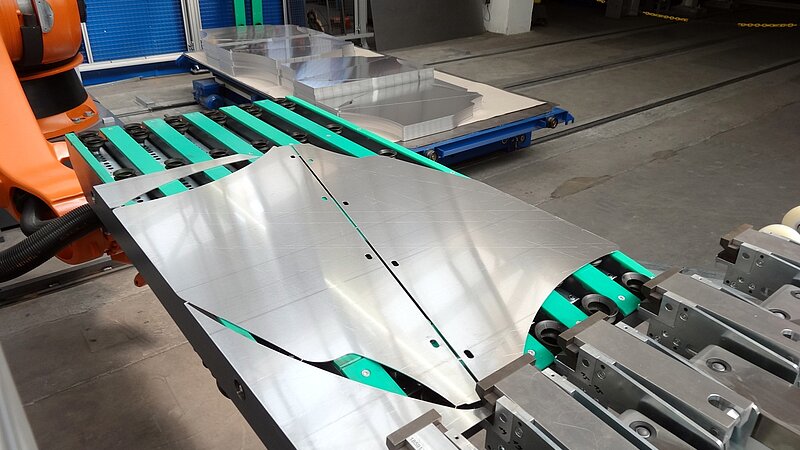

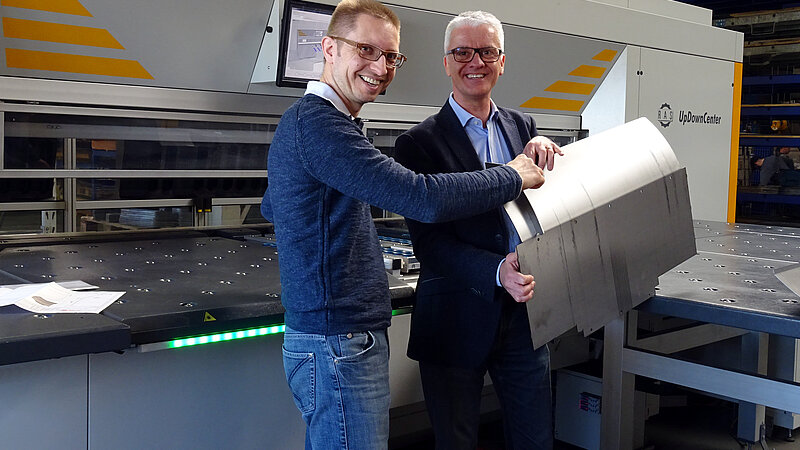

The Roessler GmbH from Mertendorf in Germany is a job shop that specializes in enclosures of machine tools. The variety of housings and small batch quantities requires high production flexibility and a high level of vertical integration. When Roessler's customers changed their product to a design with large radii, the previous production with press brakes reached its limits. Today, a RAS UpDownCenter folding system bends the radii automatically.

www.roessler-gmbh.com

Eingesetzte Maschine:

UpDownCenter-2

The von Arb AG SAS produces sound proof enclosures. In addition, the company has established itself as a highly flexible job shop. Even special orders can usually be provided with same day delivery. "If you want to produce single customized parts, you have to consider machines that can handle Step files and automatically program the component," says Roman von Arb and adds: “For small production batches, alternating bending directions, large formats and heavy parts the UpDownCenter is unbeatable.”

www.vonarb-ag.ch

Eingesetzte Maschine:

UpDownCenter-2

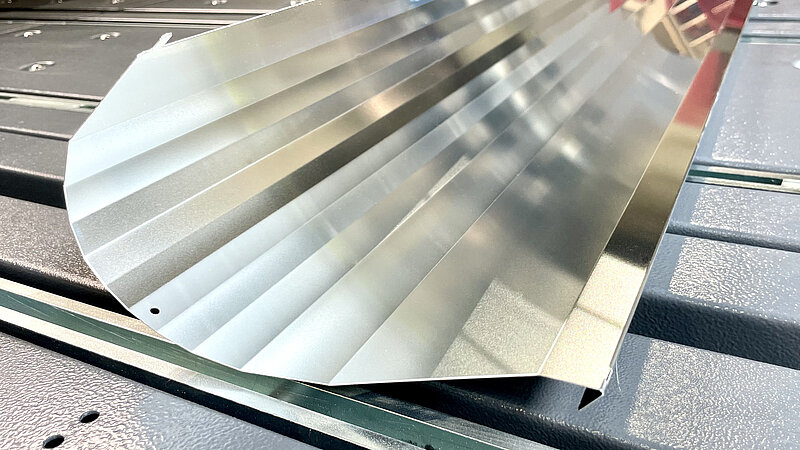

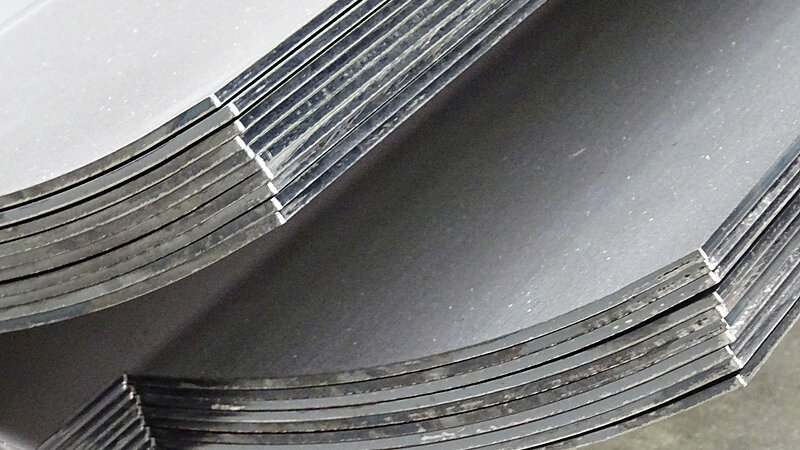

A job shop with a focus on machine cladding and containers has to be able to cover a wide range of sheet thicknesses in the bending process. The sometimes large and heavy components with large surfaces are ideal for metal folding. A wide range of challenges need to be mastered in terms of bending geometries. This includes hems, radii, inside bends, sheets with sensitive surfaces, and the full range from very thin to very thick materials. The RAS GIGAbend metal folding machine manages this balancing act perfectly.

Eingesetzte Maschine:

GIGAbend

![[Translate to English:] Die Platine bleibt immer auf dem Tisch liegen. "Die Zeiten mit Rückenschmerzen sind vorbei", bestätigt Maschinenbediener Fabian Arn.](/fileadmin/_processed_/0/7/csm_DSC00352_257aebd417.jpg)