Roofer Johannes Schwaer from the Black Forest area in Germany is a dynamically growing roofing company. The growth does not come by chance. In fact, Johannes Schwär always thinks one step ahead and wants to be prepared with his decisions for current, but also future challenges. The investment in an RAS XL-Center with UpDown bending technology illustrates the company's progressive mindset.

www.blechnerei-schwaer.de

Eingesetzte Maschine:

XL-Center

Where formerly cable car stations were located in windy heights, skier and hiker nowadays expect a luxury ambience. Modern cable car station today are comfortable building that offer much more than just wind and weather protection. The lift stations of the Doppelmayr cable cars are known worldwide. Salzmann Formblechtechnik GmbH produces the sheet metal covers for cable car stations on a RAS GIGAbend folding machine.

www.formblechtechnik.com

Eingesetzte Maschine:

GIGAbend

Tecnic Metal Listes near Barcelona, Spain, is a metal builder specialized in the metal doors, projecting roofs, fireplaces, stairs and window frames. May the special requirements of the architects be extremely special, Angel Rodriguez and his team, will take any challenge. With the RAS GIGAbend and several sets of tool, the small company meets nearly all requirements. Angel Rodriguez appears perfectly satisfied with his decision for the RAS GIGAbend. “The machine has so much free space that we can custom-design parts profitably even in small batches.”

www.tecnicmet.com

Eingesetzte Maschine:

GIGAbend

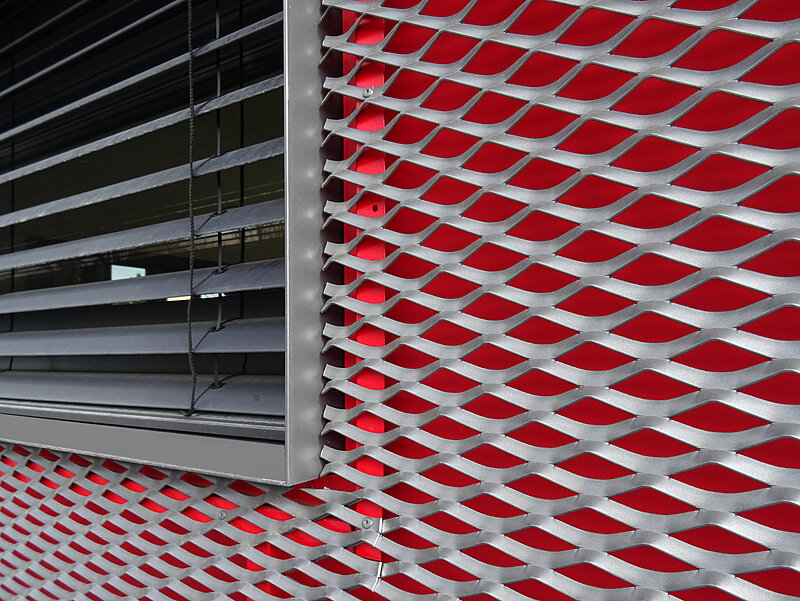

Geerds Metallbau GmbH brings over 40 years of experience and expertise to its façade projects. The façade specialists from Groß Welzin combine innovative product technology with state-of-the-art production technology. The RAS UpDownCenter complements the range of services offered by this leading provider of façade technology. The Bendex software programs the bent parts with a single mouse click. With the automatic tool change and scratch-free swivel bending technology, Geerds can also bend complex and visually sophisticated components in small quantities in a highly profitable manner.

www.geerds.de

Eingesetzte Maschine:

UpDownCenter-2

Die Firma AD-Tech aus Tschechien hat auf einer RAS FLEXIbend die kompletten Fassadenblech für das "The Diamond" genannte New Engineering Building der Universität Sheffield gebogen. Dieses fantastische Gebäude ist ein idealer Ort zum Lehren und Lernen. Die Fachrichtung Engineering hat das Gebäude bezogen, das mit Hörsäle, Seminarräume, Labore, eine Bibliothek, Sozialräume, sowie ein Cafe beherbergt.

Eingesetzte Maschine:

FLEXI2bend

The video shows the RAS UpDownCenter folding an aluminum composite facade panel. During the bending sequence the material clamping position for the upper beam tools needs to be considered.

Eingesetzte Maschine:

UpDownCenter-2

For the assembly of facade cassettes there are different techniques. Facade elements with suspension hooks can be quickly mounted on the construction site. The semi-automatic panel bender RAS UpDownCenter produces such facade cassettes from blanks with pre-formed hooks.

Eingesetzte Maschine:

UpDownCenter-2

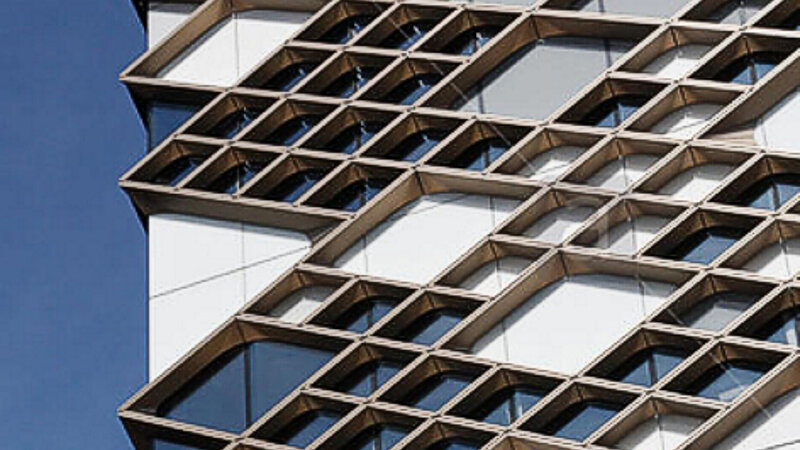

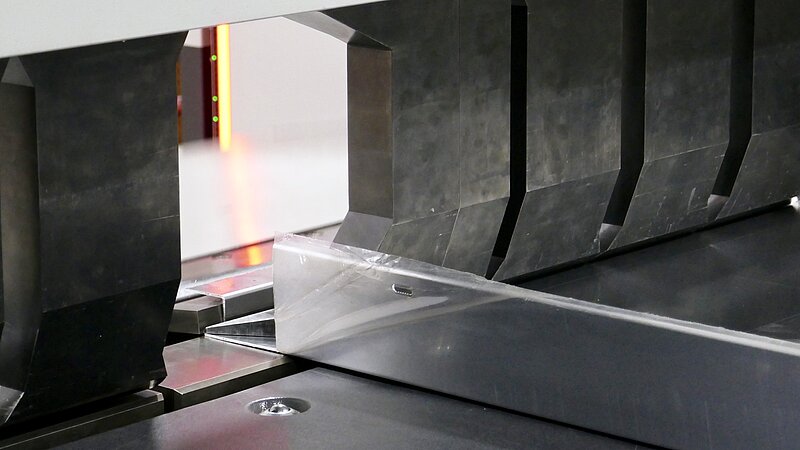

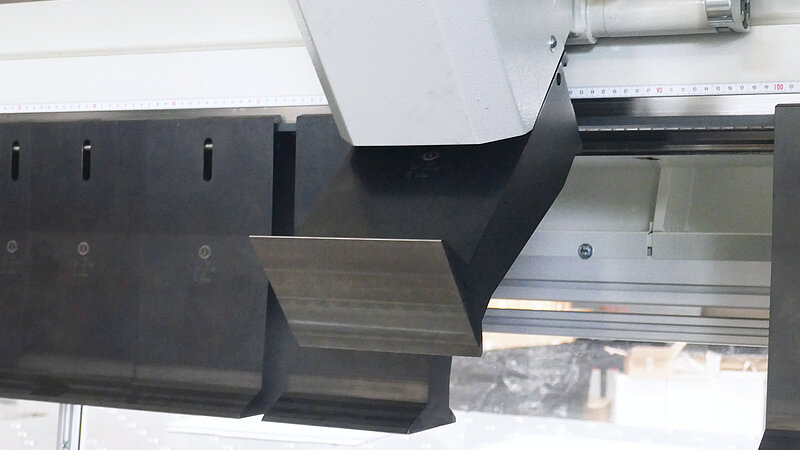

Anyone who imagines a skyscraper with a glass facade probably does not think about how many bent metal parts it contains. The Canadian company BVGlazing has specialized in this industry and bends the parts using an XLTbend UpDown folding machine. After importing a STEP file of the part, the Bendex software calculates the ideal bending sequence. The operator at the machine only calls up the provided program and places the tools in accordance with the setup instructions, Stop fingers position the blank for each bend on the bend line. Suction cups in front of the stop fingers hold the part in position. This allows the updown bender to automatically process complete sequences with multiple positive or negative bends without the operator being involved in the actual bending process.

www.bvglazing.com

Eingesetzte Maschine:

XLTbend

The company Les Ateliers de Yèbles as a job shop has specialized in the production of facade elements. The requests of the architects sometimes are very special and constantly require new part design variations from the technical department at Yèbles. Flexibility is also needed in production as the production quantities often only range between ten and forty identical parts. The RAS UpDownCenter meets these requirements brilliantly.

Eingesetzte Maschine:

UpDownCenter-2

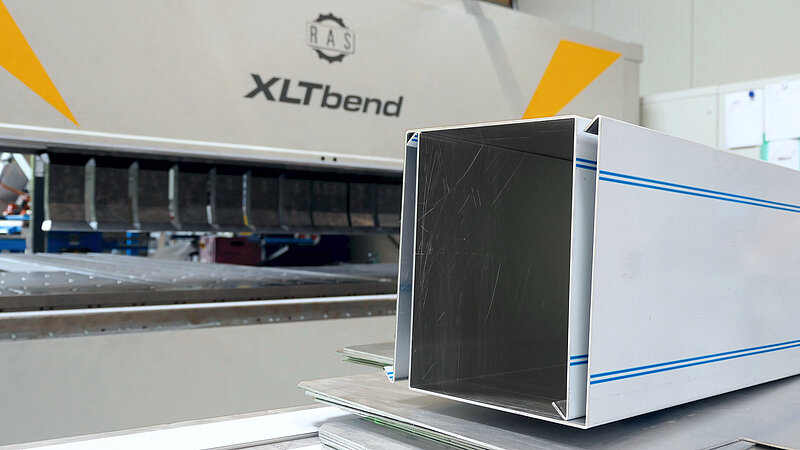

The Germany based Burckhardt Group is a specialist for metal facades, windows, doors as well as metal profiles and panels. On the other hand, the metal construction specialist acts as a job shopper for cut, punched, bent and coated sheet metal components. Both areas have in common the digital consistency in sheet metal production. automatically programmed parts get directed to the UpDown folding machine RAS XLTbend. Burckhardt produces all facade panels up to 3 mm aluminum on the XLTbend. The 6 mm RAS GIGAbend folding machine processes thicker and larger sheetmetal parts. Only even thicker, and mainly structural profiles, are scheduled for the press brake. "On large facade panels with positive and negative bends, the XLTbend is 2-3 times faster than the GIGAbend and only requires one operator. A press brake could not even come close to the cycle of the GIGAbend."

Eingesetzte Maschine:

XLTbend

For two generations, Begoin GmbH has stood for solid and reliable roofing. Due to the precise processing of high-quality materials, the Bad Hersfeld company has made a name for itself in the regional roofing market. Three RAS machines help to keep the performance promises regarding quality and delivery reliability. The cuts are done by a RAS SMARTcut swing beam shear. For bending, a RAS TURBObend plus and the updown profile bender RAS XL-Center are used.

Eingesetzte Maschine:

XL-Center

Several industrial companies think that metal shears have no future. However, there is no economical way around shears when it comes to cutting strips and rectangular blanks. Neither punches nor lasers can compete with the efficiency of the shears for such jobs. This is also the case at Gramm GmbH & Co. KG, a specialist for modern, innovative metal roof and facade solutions, who invested in a RAS Powercut2 swing-beam shear.

Eingesetzte Maschine:

POWERcut2

![[Translate to English:] Inhaber Johannes Schwär und Maschinenbediener Timo Schweizer](/fileadmin/_processed_/6/7/csm_Schwaer_Schweizer_7755b718c3.jpg)

![[Translate to English:] Verschiedene Biegeteile eines Bauprojekts](/fileadmin/_processed_/a/6/csm_Biegeteile_2_9e60e173d2.jpg)

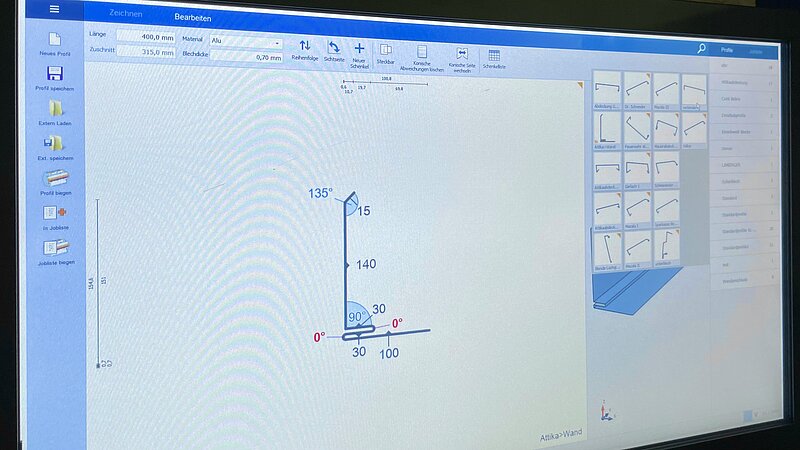

![[Translate to English:] Aufrufen eines Biegeprogramms aus der Bendex-Software](/fileadmin/_processed_/3/8/csm_Bildschirm_1_307229510c.jpeg)

![[Translate to English:] Konische ineinander steckbare Biegeteile](/fileadmin/_processed_/b/0/csm_Konisch_biegen_Schwaer_5c41906f7b.jpg)

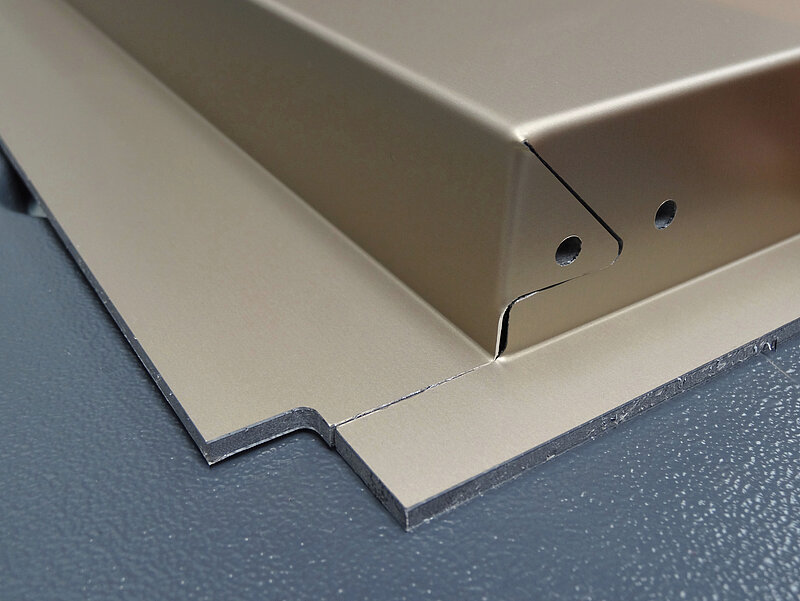

![[Translate to English:] Mauerabdeckung](/fileadmin/_processed_/f/b/csm_Ausfuehrung_Mauerabdeckung_2bef6a856b.jpg)

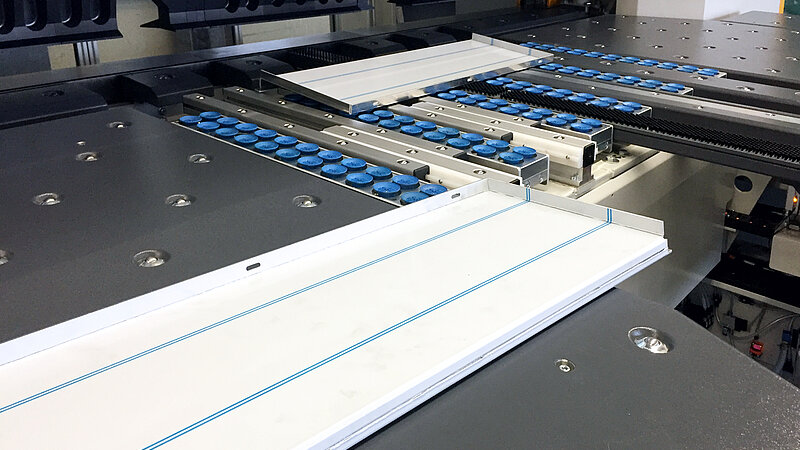

![[Translate to English:] Einlegen eines Zuschnitts in das XL-Center](/fileadmin/_processed_/a/c/csm_Blech_einlegen_2_8117dba61b.jpg)

![[Translate to English:] Biegen einer Aluminiumbox mit hohen Werkzeugen](/fileadmin/_processed_/5/1/csm_Biegen_Box_2_37cb0f04bb.jpg)

![[Translate to English:] Programmierung der Biegeteile wahlweise im Büro oder an der Maschine](/fileadmin/_processed_/a/7/csm_Progammierung_94676a81d5.jpg)