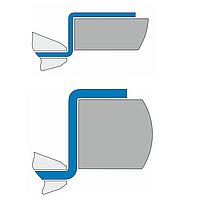

UpDown bending technology

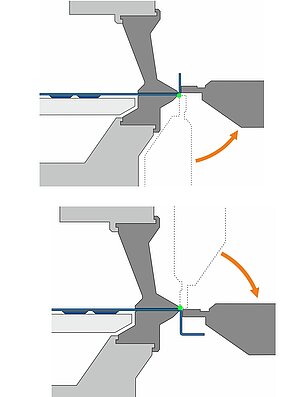

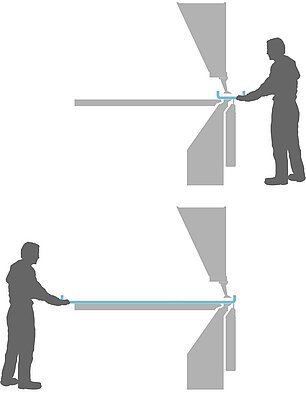

The XLTbend can be operated from the front and from the rear. With the new and double-monitoring safety system, even a front operation with UpDown bending technology is possible.

- No material flipping required

- Program controlled folding beam pendulum movement (zero setup time)

- Passing pre-bent flanges (150 mm folding beam stroke)

- Deep folding beam (perfect bending accuracy)

- Quick and easy operation. Short cycle times.

- Automatic folding sequence per station and part side

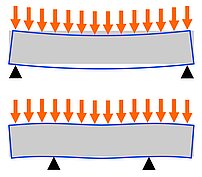

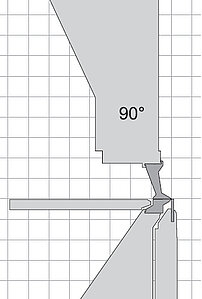

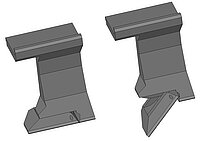

Revolutionary folding beam design

The patented “Beam-in-Beam” concept reduces the deflection of the folding beam to a minimum. This design achieves incredibly straight bends. An additional crowning axis is completely unnecessary, and the folding beam can be used as a stop in the pivoted 90 degree position. The adjustments for sheet thickness and bend radius are also performed automatically.

- Patented “Beam-in-Beam” folding beam design

- Minimum deflection of the folding beam

- Straight bend without a crowning system

- Folding beam can be used as a stop for angular parts

- No set-up times due to automatic adjustment to thickness and radius

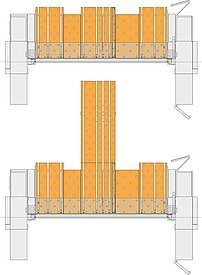

Hybrid gauging system

The RAS hybrid comes with a combination of stop fingers and suction cups. The stop fingers position the workpiece on the bending line. At the same time, suction cups hold the blank at the stop finger so that subsequent bends can be made without operator intervention. After one side of the part is finished, the suction cups pull the part back to the operator when working from the gauging system. This allows the operator to rotate and position the part conveniently. The modular gauging system concept allows a choice of a rectangular or an extended T-shape gauging system.

- Hybrid gauging system eliminates misalignment (precision parts)

- Stop finger rows separately controlled (fast positioning)

- Rigid stop fingers (long-term accuracy)

- Lockable stop fingers (coil material with warped or uneven edges)

- Active squaring arm (aligning of long and narrow parts)

- Small panel improves rear access

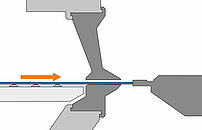

ViN (Virtual Navigator)

The ViN (Virtual Navigator) shows the operator the exact part loading position with an intelligent laser beam. The software calculates the position of the visible edge of the blank in accordance with the actual tool setup. When working from the gauging system, smaller parts can be easily loaded at the end of the gauging table (support function).

- Laser beam shows the exact part loading position

- ViN moves along the working length under program control

- Laser shows loading position on folding beam and gauging system side

- Loading position matches to the tool set-up (also with a multi-station setup)

- Quick and precise part loading

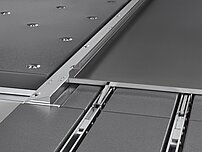

Universal tooling system

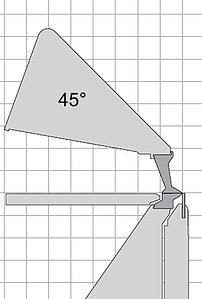

RAS has created a maximum free space in front of and behind the upper beam tools of the XLTbend. With tools up to 400 mm tall, the XLTbend is ready for all applications. A variety of folding beam tool are available for the smallest Z dimensions or thicker materials. Nevertheless, many users just need a single set of tools for their entire production range.

- Quick set-up due to handy tool segments

- Automatic tool clamping

- Sharp tool (for 45 degree upper beam)

- Tool heights: 155, 200, 250, 300 and 400 mm

- Front-free and rear-free tool geometries

- Folding beam tool widths from 6 to 18 mm

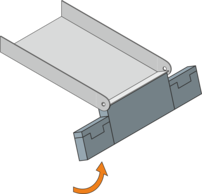

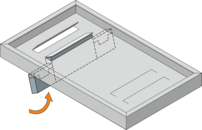

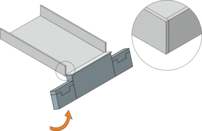

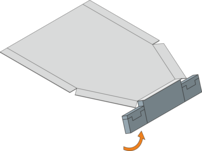

SnapTool corner tools

The SnapTool corner tools with a hinged foot automatically retract from parts with side flanges. The hinged foot moves down when the upper beam opens and snaps back into the working position as soon as the tool has moved out of the bent part.

- Automatic bending sequences: A manual rotation of the bent parts at the end of the bending cycle is not necessary

- Working from the gauging system: The bent part can be returned to the operator using the support function

- Side free space in the hinged area of the SnapTool is 30 mm

- Designed for the same sheet thickness as the other tools of the tool set

- Software calculates the SnapTool positions

Tools with radius

For some materials, material manufacturers recommend the use of radius tools. The larger bending radius avoids cracks on the material surface. Especially when bending thick aluminum, the radius tools lead to excellent bending results. For machines with UpDown bending technology, such as the XLTbend, the tools of the upper beam and the lower beam should have a radius.

- No cracking of the material surface

- Only slight paint thinning on pre-coated sheets

Folding beam tools with plastic insert

In contrast to press brake bending, which usually leaves clearly visible pressure and scratch marks next to the bending line, metal folding can also be described as gentle forming. This makes a considerable difference in quality for parts with a demand on the optical finish. However, if upper beam tools with a radius are used instead of sharp tools, the sliding section of the folding beam tool on the material surface will be also longer. In such applications folding beam tools with a plastic insert avoid pressure marks on high-quality material surfaces.

- Bending of pre-coated sheets and stainless steel parts (sometimes even without protective film)

- The parts shown are bent with radius tools and without protective film

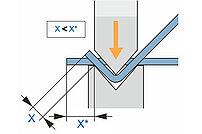

Incline folding beam tools

On metal folding parts with inside bends , the folding beam often cannot pivot to the programmed angle. The folding beam would be destroyed the part during its movement to the 90 degree angle. In such cases, incline folding beam tools are used. By the shape of the tool, the material will be pre-formed, while the upper beam clamps the part. The folding beam therefore only needs to pivot the remaining angular degrees to create a 90-degree bend. The body of the olding beam remains below the horizontal protruding part.

- Segmented offset tools allow for exact tool setup lengths

- Inclie corner tools for mitered window bends

- Bendex software considers incline folding beam tools

DownTools

With the DownTools in the folding beam, interrupted flanges can be bent without an additional tool setup. Simply move down the DownTool manually. The software programs the position of the DownTools and allows access for down or up positioning during the bending sequence. The DownTools can be used for:

- Louvers

- Parts with an angled base shape

- Flanges bent towards the inside

- Interrupted bending lines

- Protruding flanges

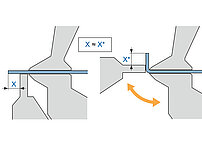

XL Folding Beam Tools

Some applications require additional free space in front of the folding beam tools. The XL folding beam tools provide the additional space for these applications. They are available for tool widths of 8, 10, 12, 14 and 18 mm.

Sometimes the clearance for negative flanges is needed on the rear end. A special folding beam tool with the XL clearance on the back side offers the solution in this case. [Video]

- Clearance for flanges directing towards the folding beam tool

- Extended part range for special applications

- Bendex software incorporates the XL folding beam tools

Higher folding beam tools

Optional higher folding beam tools can be added to the RAS XLTbend up-down folding machine. If, in some situations, more free space is required between the upper edge of the folding beam tools and the body of the folding beam, these higher tools expand the range of applications for the machine.

- Additional bending capabilities

- More free space between tools and folding beam

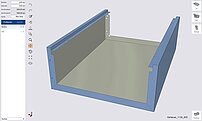

One-click programming of the bending sequence

Where experience and expertise were formerly required for programming, this intelligence is embedded in the machine software. Either the operator on the floor or the engineer in the office directly imports STEP, DXF, or GEO files … and that is it! A simple mouse click is all that is required to program the complete setup and bend sequence automatically.

- Exact and error-free transfer of CAD data

- Automatic programming of the bending process

- No expert knowledge required

- Software suggests the best folding sequence with a 5 star ranking

- 3D simulation of the bending process

- Highest bending accuracy due to material tables

- Loading individual programs or processing job lists

- Online support via TeamViewer