Punching-bending lines

The Partners

RAS and Pivatic are well-known, top-performing and established manufacturers of sheet metal working equipment on the market. The two companies contribute their know-how in punching and bending and offer punching-bending lines as a joint solution.

Pivatic, based in Finland, was established in 1975 and is today part of the Ursviken Group. More than 450 sheet metal processing lines are a convincing proof of the efficiency in automatic punching.

RAS completes the lines with its Multibend-Center panel benders and can also palletize bent parts or forward them to downstream systems using additional automation components.

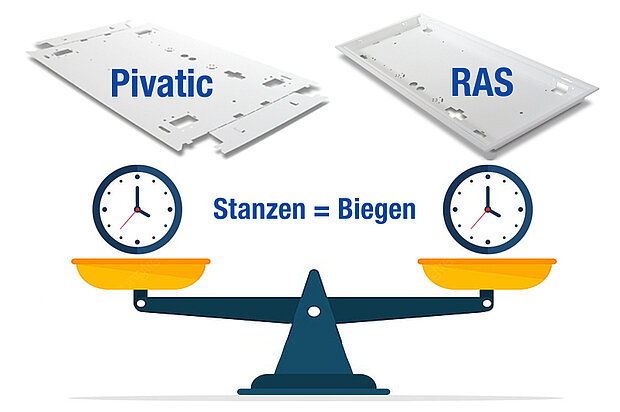

The Concept

The unique Pivatic-RAS solution integrates two sheet metal processing technologies in a single production line: punching by Pivatic - bending by RAS. Compared to other systems, the material moves only once through the Pivatic punching machine. The result is a punched part produced faster than with any other flexible flexible punching system.

This punching speed, combined with the bending speed and flexibility of the RAS panel bender, results in an automated manufacturing solution that features low cycle times, high productivity, low logistics and handling requirements, high part design flexibility, and low cost per part.

The integrated line is very compact and requires minimal shop floor space. Due to the flexibility of both technologies, this fantastic and modular line is suitable for high production batches as well as for small quantities down to batch size 1.

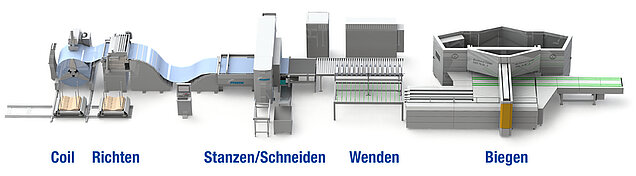

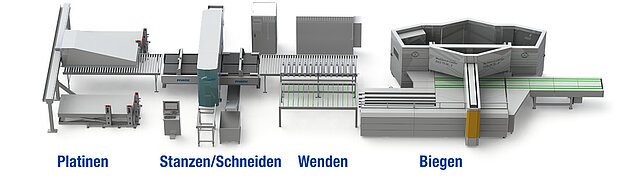

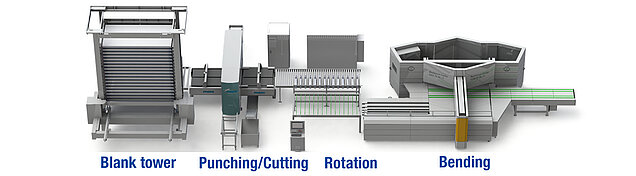

The Production Process

The punching process can start from sheet metal blanks or from coil. The RAS bending module can consist of one of three panel benders (RAS 79.22-2, 79.26-2, 79.31-2). Additional slitting and cut-to-length shears provide precise blanks for the bending process. After bending, the palletizer optionally stacks the finished parts.

The Software

A line control software organizes data communication to the components of the production line, sends information to an ERP system and generates statistical data. State-of-the-art technology complies with industry standard 4.0. Programming of the punching and bending sequences based on 3D and 2D CAD drawings can also be carried out automatically.

The Benefits

- Reduced logistics effort and improved material flow

- Reduced work-in-process inventory

- Reduced human errors due to automated processes

- Synchronized processes increase throughput and efficiency

- Low costs per part due to short cycle times

- Up to 120 punching tools simultaneously accessible (no changeover times)

- No punching skeleton

- Automatic blank loading, squaring, positioning, bending and unloading

- Fast up/down folding sequences without flipping the part

- Highest level of bending precision and repeatability

- Automatic tool setup

- Scratch free bending, no wear of toolsr

- Optional stacking or forwarding of finished parts

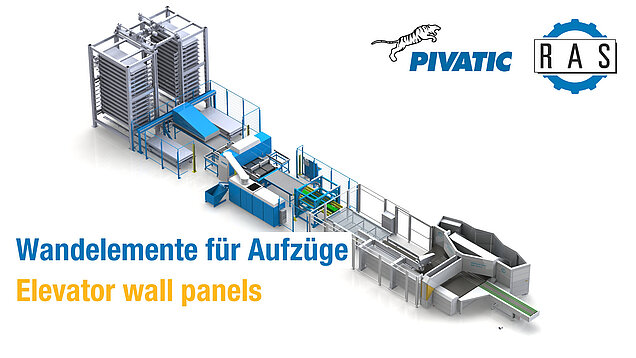

Applications

The video shows how an automatic production line punches and bends wall panels for elevator cabs. The Pivatic punching line starts from blanks and punches the panels in one pass through the punching machine. After rotation of the sheets, the RAS Multibend-Center panel bender automatically bends the wall panels. Each panel can be different in geometry, dimensions and material.