Bending sequence

Amazing clamping pressure

The upper beam moves down and up with a spindle drive. For clamping the parts PowerBoosters are activated. They create 120 metric tons of clamping pressure, hold thick workpieces in position and have sufficient reserves for hemming.

- Large-volume upper beam for straight bends

- Large open space around the upper beam (design freedom)

- PowerBooster (secure material clamping, hemming power)

- Long and deep guiding system (high bending accuracy)

- Encapsulated spindle drive in an oil bath (low maintenance)

- Large free space behind the upper beam (view from behind)

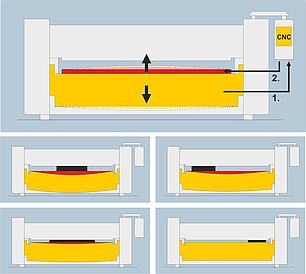

High-Tech folding beam

The folding beam is the heart of each folding machine. The intelligent crowning system of GIGAbend automatically compensates elastic beam deformation caused by the bending forces. Sensors measure the beam deflection. The results are straight bends and precision parts.

- Fast movements: short cycle times

- Deep folding beam: Excellent bend results

- Automatic clamping of segmented folding beam tools

Straight bends without test bends and without programming for:

- Thin and thick materials

- all material types (mild steel, stainlessm aluminum, etc)

- long and short flanges

- in the machine center or close to the machine stands

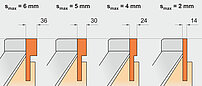

Automatic material thickness and radius adjustment

On a program change, the machine automatically adjusts in 5 seconds to the new sheet thickness and bending radius. A digital display provides additional comfort during the folding beam initialization.

- Automatic folding beam adjustment to material thickness

- Automatic pivot point adjustment for perfect bend radii

- High productivity due to less change-over time

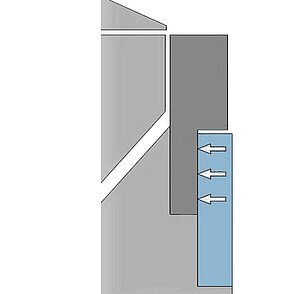

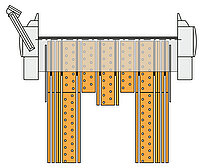

Versatile gauging system

The gauging system positions the part for each bend. It supports the weight of the large and heavy components. The stop fingers can be lowered in any program line so that the workpiece does not collide during rotation.

- Accurate and repeat bends

- No 2nd operator (50% cost)

- Fast positioning by changing from a front to a rear stop finger

- Ball casters in table for easy movement of the workpieces

- Space-saving stop configurations: Rectangle stop, J-, U-shape systems

- Squaring arm for narrow and long parts

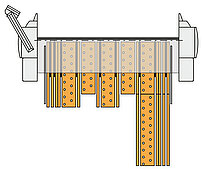

Tools for every application

The tools of the upper beam, folding beam and lower beam are segmented. The front-free or rear-free geometries provides plenty of space for long C-flanges or narrow components. Different tool heights and shapes cover the variety of bending challenges. In case of a focussed part analysis a single tool set is often sufficient for the entire range of parts.

- Tool segments can be easily handled by a single person

- Short set-up times due to automatic tools clamping

- Perfectly fitting tools segments (retrofittable at any time)

- Folding beam tool width selected for sheet thickness and smallest Z dimension

- XL-folding beam tools with extra-large free space

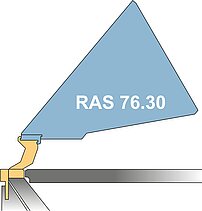

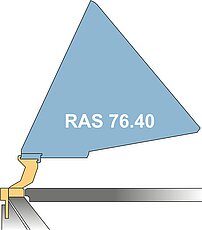

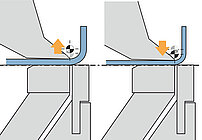

Radius tools in the upper beam

For some materials, material manufacturers recommend the use of radius tools. The larger bending radius avoids cracks on the material surface. Especially when bending thick aluminum, the radius tools lead to excellent bending results.

- No cracking of the material surface

- Only slight paint thinning on pre-coated sheets

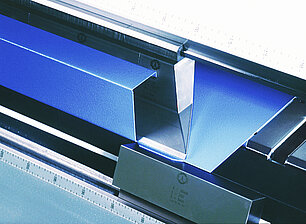

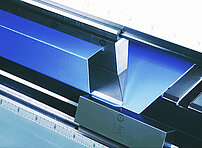

Folding beam tools with plastic insert

In contrast to press brake bending, which usually leaves clearly visible pressure and scratch marks next to the bending line, metal folding can also be described as gentle forming. This makes a considerable difference in quality for parts with a demand on the optical finish. However, if upper beam tools with a radius are used instead of sharp tools, the sliding section of the folding beam tool on the material surface will be also longer. In such applications folding beam tools with a plastic insert avoid pressure marks on high-quality material surfaces.

- Bending of pre-coated sheets and stainless steel parts (sometimes even without protective film)

- The parts shown are bent with radius tools and without protective film