Welcome to the Future

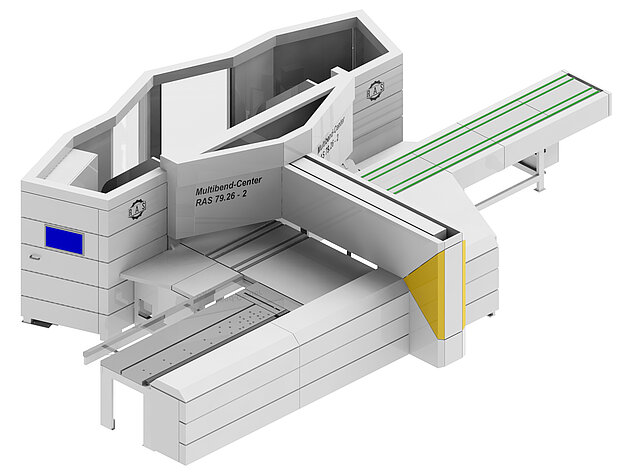

Are you facing a shortage of skilled workers in sheet metal processing, rising production costs, long setup times, or challenges in maintaining consistently high bending quality without rework? Then it is time to enter a new dimension of metal fabrication. The RAS Multibend Center fully automates your bending processes, from loading and positioning to precise alignment and unloading fast, scratch-free, accurate, and flexible, regardless of batch size.

Experience how maximum productivity and outstanding repeatability can transform your manufacturing operations sustainably. The Multibend Center is available in three working lengths: 2160 mm, 2560 mm, and 3060 mm.

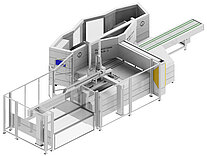

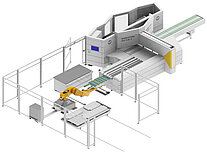

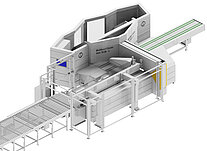

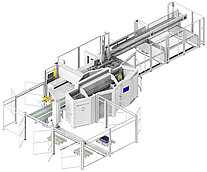

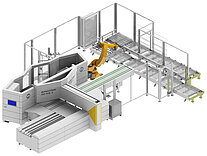

Layouts

In addition to manual loading and unloading, there are a variety of options for automatic blank loading and unloading and stacking of finished parts.

Depending on the requested degree of automation, the manufacturing conditions and the available budget, multiple handling systems can be added to the Multibend-Center. Automation components can be added on the loading as well as on the unloading side. A direct linking of punching and bending is also possible in various configuration levels. Due to the modular design of the panel bender, later upgrades are also possible.