XLTbend 2

The new XLTbend 2 sets new benchmarks in modern folding technology.

It is the ideal solution for users who need to produce complex precision parts such as cassettes, panels, and boxes efficiently and economically — even in small and medium batch sizes.

Its intelligent crowning system, reinforced folding beam, and an overall optimized machine structure ensure maximum precision and open up new possibilities in modern sheet metal processing.

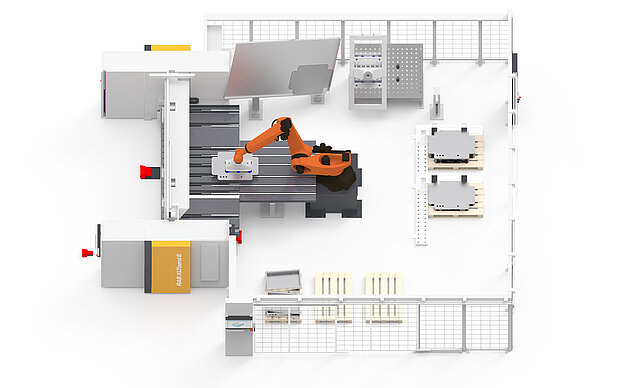

With innovative robot integration and the powerful RAS automation platform LUNA, the XLTbend 2 enables fully automatic loading, operation, and unloading. This makes the entire production process faster, more ergonomic, and significantly more efficient.

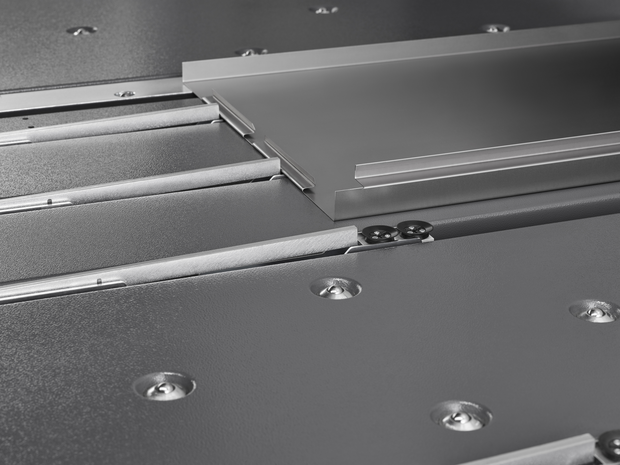

- Intelligent crowning system for perfect bending angles

- Reinforced folding beam

- New servo drives (IE5+) for maximum efficiency

- 3-in-1 hybrid backgauge with stronger suction force and integrated vacuum pump

- Robot integration + LUNA for fully automated processes

- XL tools, SnapTools, and DownTools

- ViN (Virtual Navigator): shows the part loading position

- Ideal solution for users with high demands on flexibility

XLTbend 2 is an

impressively flexible

UpDown folding machine

Automated sheet metal processing with robot integration

The XLTbend 2 is perfectly suited for automated production processes.

- Optional robotic loading with automatic part feeding

- Seamless integration into existing production lines via LUNA

- Easy robot control through the LUNA software

- Reduced setup effort and highly reproducible results

Ideal for increasing productivity and ensuring consistently high quality.

More power, precision, and energy efficiency

The new XLTbend 2 delivers maximum performance on every level, combining state-of-the-art technology with a clear focus on precision, automation, and energy savings.

One of its key highlights: significantly improved energy efficiency.

Thanks to the transition from IE3 asynchronous motors to modern IE5 or higher servo drives, the XLTbend 2 achieves a major technological leap forward. The result: more power, less energy consumption, and a truly sustainable contribution to efficient and eco-friendly production.