Software versions

Have you signed a software update agreement?

This allows you to update your Machine and Office Software to the next level.

- Includes free Machine software updates

- Includes free Office software updates

- Machine software and Office software versions must match

- For updates of additionally purchased Office licenses, the update packages for subsequent licenses are required

- Online connection to the PC must be available

What do I need to do?

Please contact RAS. After checking the data, we will contact you. We need the following information:

- Adress

- Contact person with Email and Phone

- Machine number

Version 3.1.2.27436

- New step bending interface for radii bending incl. correction tables

- New upper beam tools implemented

- New folding beam tools implemented

Version 3.1.1.25907

- New bending strategies (bending flanges longer than folding beam stroke)

- New folding beam, upper beam and lower beam tools

- Integration of the pneumatically actuated safety window (toolcover)

- Configuration level implemented

- New machine models implemented

- Unnecessary tool changes eliminated

- Installation routines for models and versions adjusted

- Web interface extended with "getmachinedata" function (Industry 4.0)

Version 3.0.13.23985

- New folding beam tools implemented

- New upper beam tools implemented

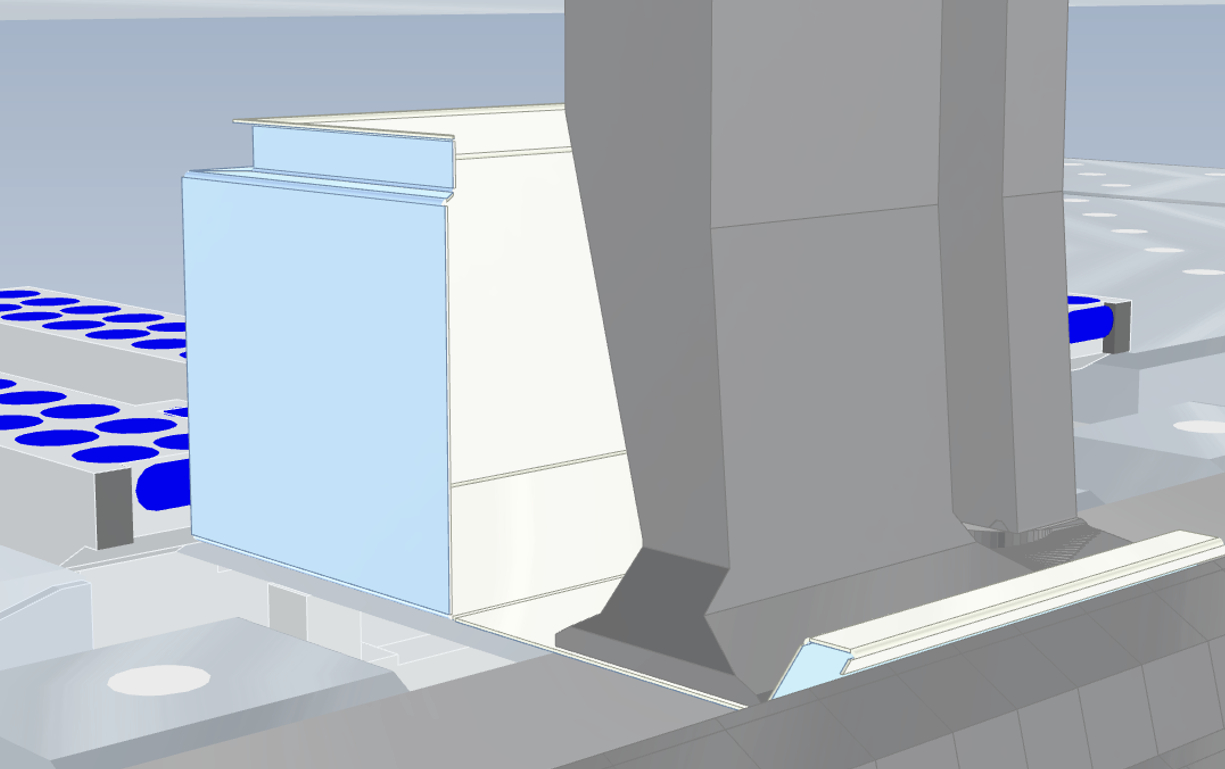

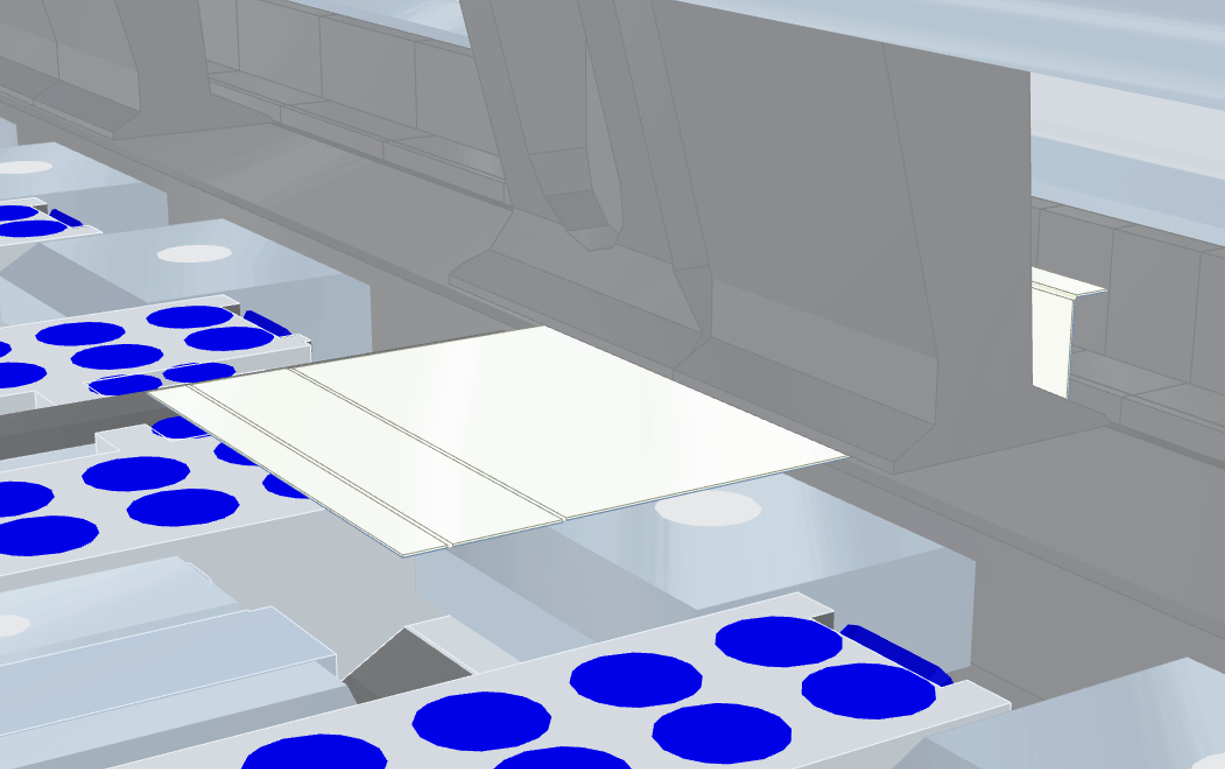

- New machine models with table extensions

- Tool meta data implemented

- New calculation formula for folding beam and pivot point adjustment

- New and improved collission calculation

- Folding sequences optimized

Version 3.0.11.23097

- New folding beam tools implemented

- New upper beam tools implemented

- Folding strategies optimized

Version 3.0.7.20475

- New folding beam tools implemented

- New upper beam tools implemented

- Front stop at oblique edges

- Improved gauging strategies for complex bending strategies

- Calculation of the folding beam and pivot point adjustment, depending on the bend radius instead of the sheet thickness (lower limit 1 x sheet thickness)

- Collisions considered between suction table and ToolCover during unloading

- Automatic foot switch display updated

Version 3.0.6.20152

- New folding beam tools implemented

- New upper beam tools implemented

- New upper corner tool 80mm wide implemented

- More bending strategies: front stop on oblique part edges

- Parts with hems closed with the tool heel (improved tooling strategy)

- More bending strategies: Parts with negative closed profiles

- More bending strategies for min bending width (center piece as corner piece)

- Algorithms extended: more bending strategies (calculation time longer)

Version 3.0.4.19122

- Additional geometries for upper beam and folding beam tools

- Upper beam tool with 300 mm height

- Improved suction calculation for narrow parts

Version 3.0.3.18858

- Program start possible at any blank referencing situation

- Program exit possible after a side of the part is completed

- Additional folding strategies with front suction cups

- Additional folding strategies with optional suction cups. Used for small parts with a base dimension of 300 x 200 mm*

- Function changes speed up the overall process

- Machine data logging implemented

- Additional 350 mm upper beam tool height implemented

* For these part dimensions a special upper beam center tool is required

Version 2.3.6.15402

- Folding strategies include programs with 180 degree rotated folding beam tools

- Import of profile cross-sections

- Center bend line as the default setting for STEP import

- Turkish language

- Visual/dynamic graphic adaptation when changing the hem height

- Bends on one line will be executed all together

- Modification of the rectangular base and flange height will not result in new programming

- Improved strategy for the closing and opening of the safety screen

- STEP import of too small radii are always adjusted to 1x sheet thickness

Version 2.3.0.13502

- Software can import and program closed profiles

- Pre-bend angle for hemming with heel of the upper beam tool implemented

- Select when a profile is to be closed: program end, end of part side, in program sequence

- UpDownTool sequences improved

- 16 mm folding beam tool implemented

- STEP import shows design mistakes (red colour)

- Improved folding strategies

- If loading or storing takes unexpectedly long an hourglass is shown (eg slow network speed)

Version 2.2.3.13010

- All messages in one status window: RED = fault, YELLOW = warning, BLUE = note

- Foot switches and their actual function also shown in step mode

- Improved STEP import

Version 2.1.6.11589

- Upper beam tool dimensions and positions are always shown in mm

- Folding beam tool dimensions and positions are always shown in mm

- Gaps between tools are shown in inch, when "inch" is selected

Version 2.1.6.11584

- Calculation of suction cup allocation for smaller holes and cutouts improved

- Collision calculation with upper beam tools at oblique parts

Version 2.1.5.11460

- Folding beam height axis can be set inclined to compensate for angle differences from left to right

- Speed increase on step bending sequences

- Material tables will be linked to a programs after folding strategy selection

Version 2.1.2.10310

- STEP import of parts with intersecting bend lines

- Import of STEP files in inch dimensions: If the software cannot clearly identify the dimension, a prompt appears.

- Technology tables of the machine can be loaded into the Office software version with overwriting dialogue

- Scaling Wizard for corrected CAD File units

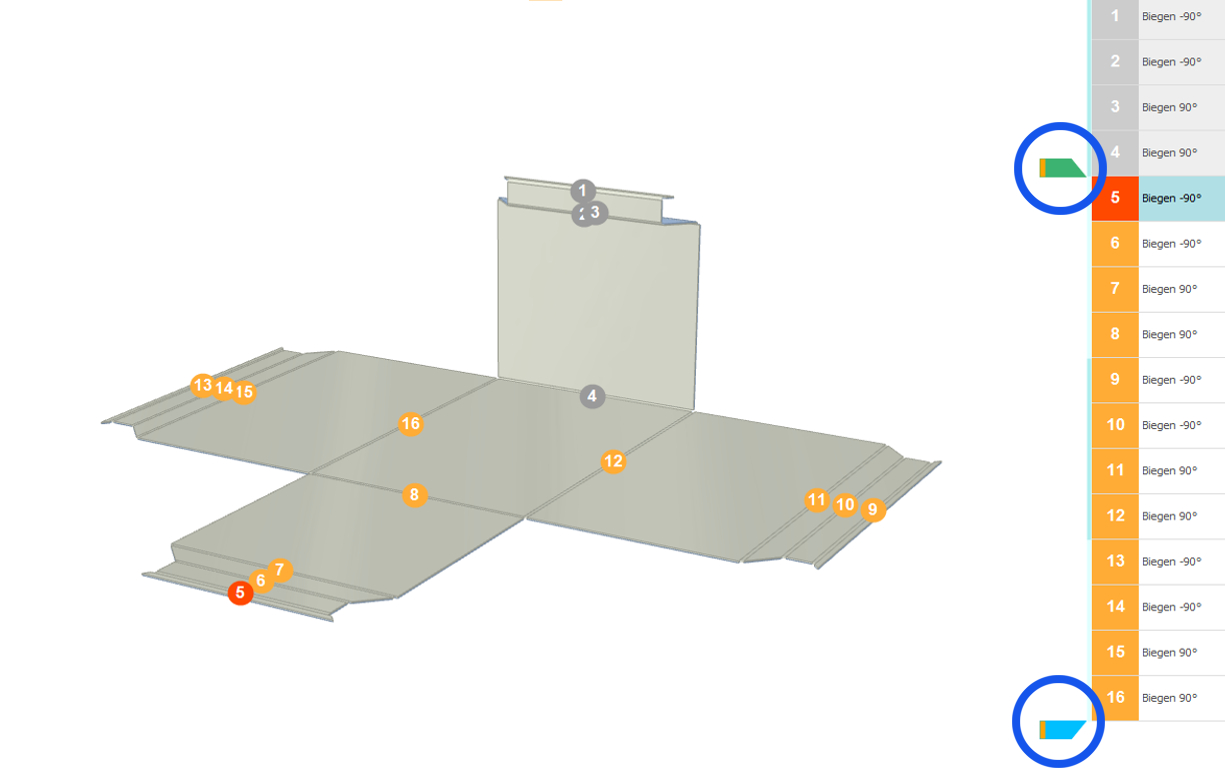

- Step bending: max. sheet thickness and step length as a parameter for the bend angle limit

- Step bending: Soft start and end of the radius

- Max overbend angle in the correction menu limited to max angle

- 9mm folding beam tool added to tool library

Version 2.0.10.9463

- Vacuum level settings and display in Bendex

- Correction of the pivot point position when folding beam is used as a stop

- Suction cup repositioning within a step bending sequence

Version 2.0.10.9405

- Parameter for the lifting negative hems. The hem height is calculated. This parameter will be added to the calculation to eventually compensate hanging down material or material springback.

Version 2.0.10.9251

- Integration of step bending sequence with parameter for min bend angle and parameter for min step dimension

- Note: Step bending is based on pure mathematical calculations

Version 2.0.8.8163

- Improved STEP import function

- Integration of option: Table extension with selection choice

Version 2.0.0.5924

- New graphical interface based on Windows Metro Design

- Import of STEP, DXF and GEO files

- Automatic repositioning of the PosLift gauging system suction cups

- Automatic part programmierung

- Automatic evaluation of alternatives (ranking)

- 3D simulation of the folding cycle

- Setup instruction for folding beam (tool positions and UpDownTools)

- Intelligent control of the tool cover (Operator instructions)

Note: Hardware requirements (also for all subsequent updates needed)

- Automatic quaring arm

- Triggering color LEDs for access control into safety area

- Third monitor in folding cell (setup instruction for folding beam and UpDownTools)