Software versions

Have you signed a software update agreement?

This allows you to update your Machine and Office Software to the next level.

- Includes free Machine software updates

- Includes free Office software updates

- Machine software and Office software versions must match

- For updates of additionally purchased Office licenses, the update packages for subsequent licenses are required

- Online connection to the PC must be available

What do I need to do?

Please contact RAS. After checking the data, we will contact you. We need the following information:

- Adress

- Contact person with Email and Phone

- Machine number

Version 3.6.1.982

- New language files implemented

- New upper beam tools implemented

- New bending beam tools implemented

- New lower beam tools implemented

Version 3.6.00.884

- New language files integrated

- Conical bending has been integrated (currently only CAD import is supported)

- Menu option for automatic alignment of boxes during CAD import implemented

- New backgauge 255017 for the 62.25 integrated

- Two-line labels for the buttons in the drop-down menu are now supported

- Offset input in the hem dialog has been removed

Version 3.5.0.44491

- new language implemented

- Import category implemented

- New upper beam tools implemented

- New lower cheek tools implemented

- Dialog entry point moved and implemented in the job list

- Interior bends are supported during importing

- View setting changed to 2D as "Default

- Program optimization for step bending

- manual alignment during STEP import implemented

- during STEP import the material thicknesses valid for the machine are requested and not imported if exceeded or fallen short of

- Length and width of the sheet unwinding swapped in the job list

Version 3.4.3.42536

- Max. sheet thickness increased to 3.2 mm (for aluminum)

- Program lines reduced for step bending

- Tools to be changed are shown graphically

- Tool menu shows max. sheet thickness

- Upper beam opens as long as folding beam moves down (SpeedOptimizer)

- SpeedOptimizer can be selected and deselected

- Length and width of imported third-party formats are calculated correctly

- Upper beam hemming dimension adjusted for hemming calculation

- Improved GEO import: partly bending lines were not recognized

- Improved GEO Import: sometimes hems were shown upside down

- Improved GEO import: the bending radius is calculated on the basis of the sheet thickness

- Background color can be selected for DXF import

- Material selection possible during STEP import (correct development calculation)

- Improved selection of the base surfaces during import

- Improved expert menu: Behavior depending on import format

- Flanges and radii larger than 2x sheet thickness can be executed as "normal" bend or as step bending radius

- Possibility of saving manually modified programs immediately without simulation

- Parts bent before are always shown at the first position in the program list. By double clicking the triangle can be deleted

- Standard dimensions of blank length and width adjusted

- New upper beam tools implemented

- New lower beam tools implemented

Version 3.4.0.40805

- 4m machine model implemented

- Machine configuration with XL folding beam implemented

- Selection of folding and lower beam tools based on folding beam geometry (standard or XL folding beam)

- New upper beam tools also implemented for 4m machine

- New folding beam tools also implemented for 4m machine

- Russian language available

Version 3.3.2.40148

- Allowed protrusion of flanges beyond the bending line is calculated in relation to the sheet thickness

- For radius tools, where the tool radius does not extend beyond the bending line, the bending formula is used as for tools with sharp tool tip

- Linear calculation for stop finger positions for bends with open angles

- Parameter for bending angle ranges adjusted

- New upper beam tools implemented

- New gauging systems implemented

OpenEditor Version 3.6.1.982

- New language files implemented

- New upper beam tools implemented

- New bending beam tools implemented

- New lower beam tools implemented

OpenEditor Version 3.3.2.40148

- OpenEditor release number needs to be identical to the release number of the Bendex graphics software

OpenEditor Version 3.3.1.39606

- Change between mm and inch

- With new deliveries, both the graphics programming software and the OpenEditor software are installed on the control. The user can choose which programming software to start.

- Improved program sequence for radius step bending

- Improved display of operator instructions for part rotation and flipping

- Improved positioning of the numerical input field

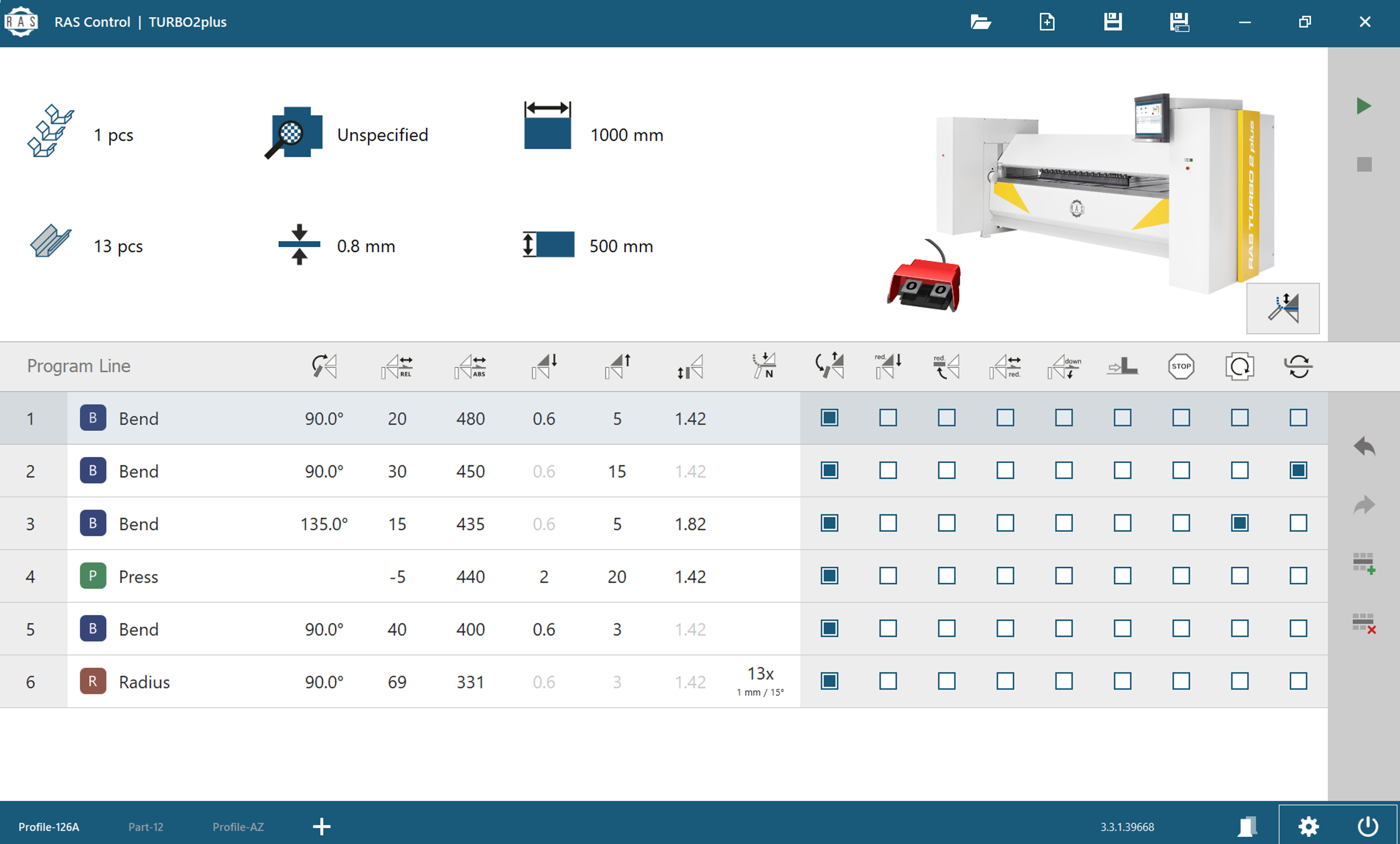

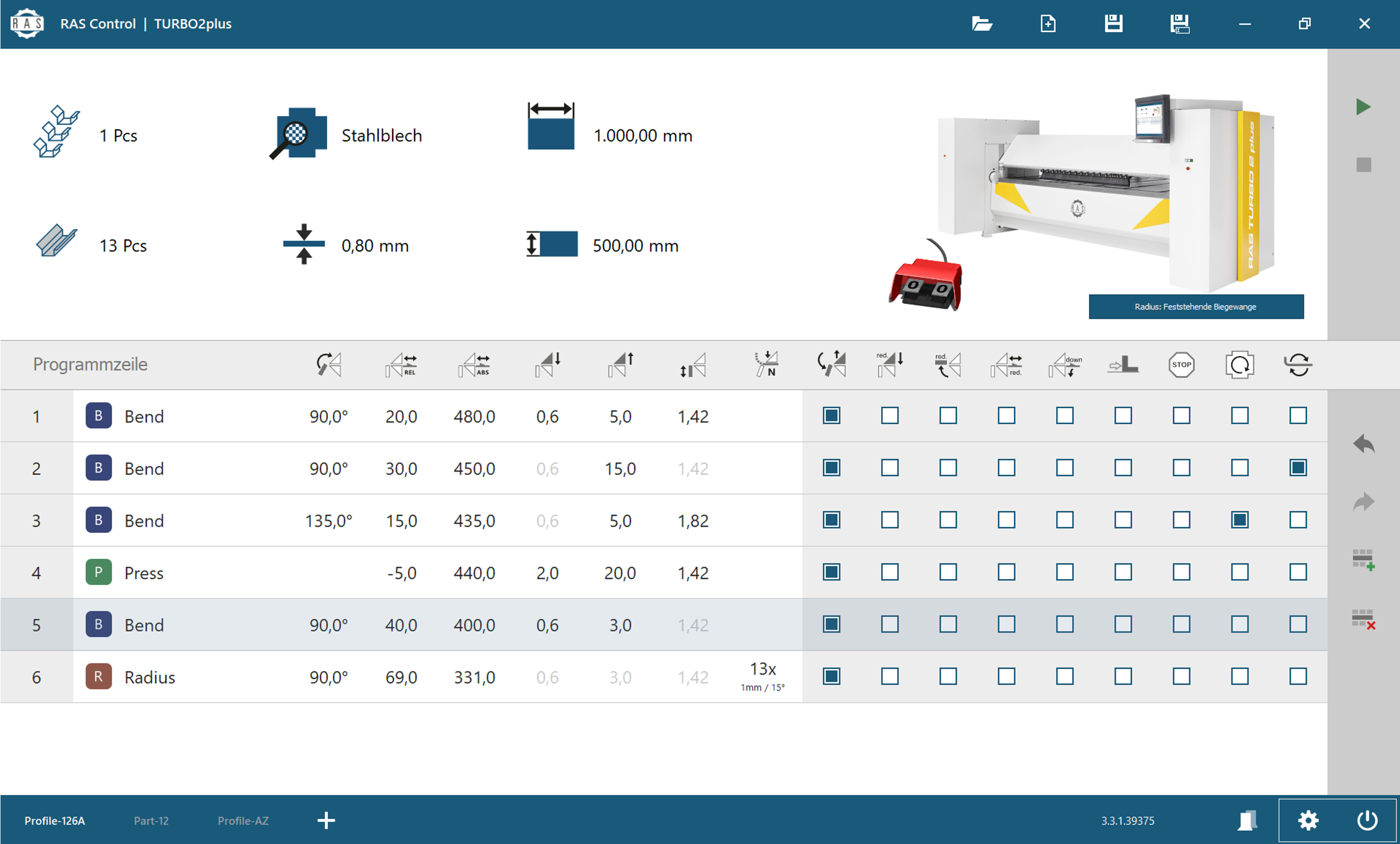

OpenEditor Version 3.3.1.39375

- Manual input of target positions for axes movements

- Bending modes: Normal bending, hemming, step bending

- Tabular display of the inputs

- Program sequence created by the operator

- No automatic program generation

- Additional functions for program optimization

- Material tables

- Tool selection for automatic tool height check

- Saving programs

Version 3.3.0.37988

- Program start possible in every program line

- During the bending process the cross section view is displayed. Other views can be selected.

- In the correction menu, the selected flange is colored

- Very narrow bent parts can be positioned with only one stop finger

- Individual part flanges can be deleted after a STEP file import.

- Graphic function "Follow sheet" implemented in bending and job list menu

- Automatic opening height of the upper beam optimized

- New upper beam tools implemented

- New folding beam tools implemented

Version 3.2.4.36285

- Manual engagement in the bending program made possible

- Programs with manual engagement are marked with a blue triangle

- On four-sided parts, sharp tools can soft clamp on the side hems

- Improved bending strategy for hems inside a profile

- Upper beam opening varies depending on the stop position

- Upper beam also opens for parts when center of gravity is outside the machine

- New upper beam tools implemented

- New gauging system configuration implemented

- Upper beam tool setup remains after changing material thickness

Version 3.2.3.35341

- Generation of programs for profiles with side hems that are bent with the sharp tool.

- Additional strategies when bending hems: Long flange protrudes from the machine when pre-bending the hem. Clamping on the short flange .

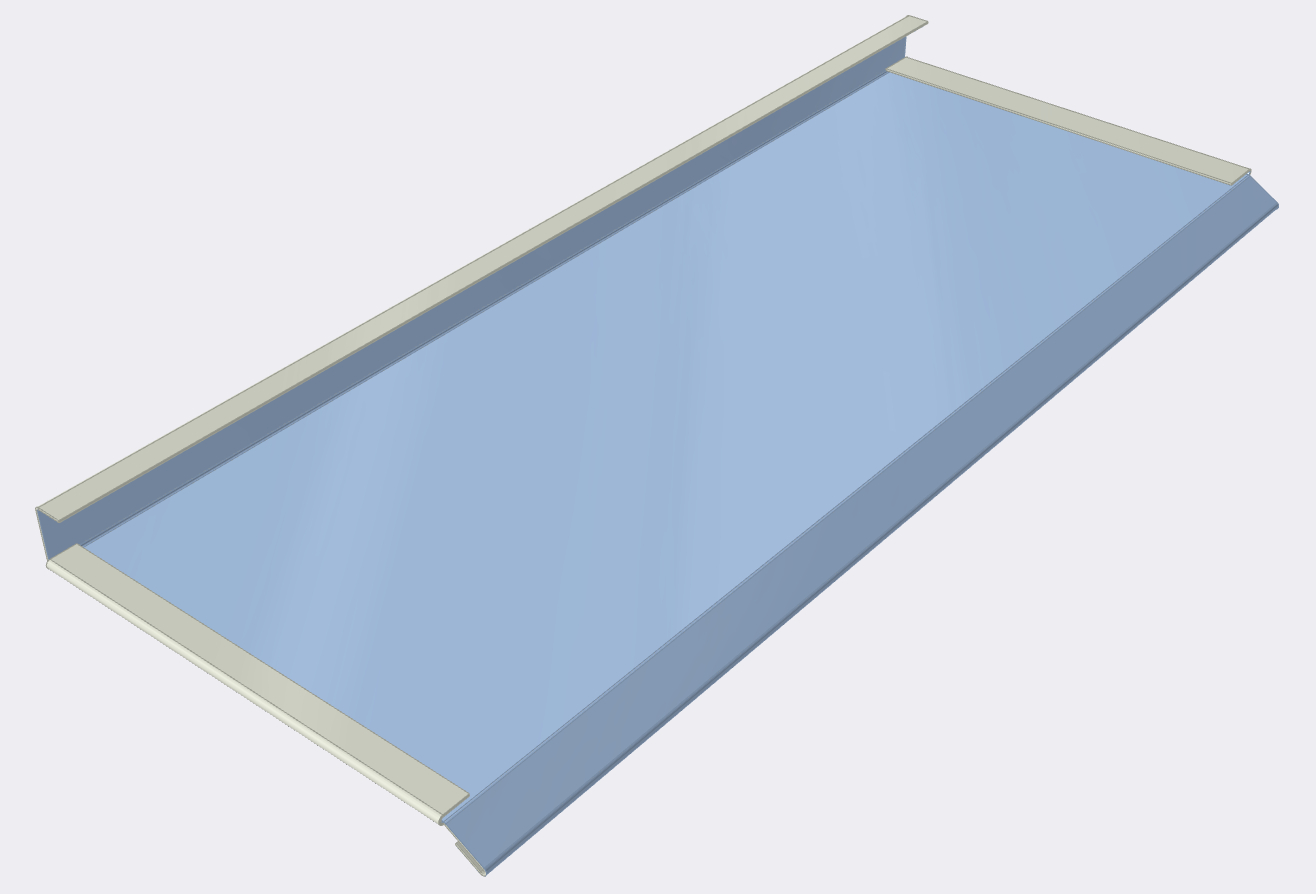

- Radius step bending:

- Material tables optimized for entering the springback correction

- Criteria for interpolation of the springback correction optimized

- Radius bending with the radius tool:

- Software takes into account that the bending radius widens after bending

- Simulated and bent parts are marked in the strategy selection

- Programming can be stopped with "Cancel". Programs that have already been generated are shown.

- Radius tools implemented

- New upper beam tools implemented

- In the "Manage tools" menu:

- Sorting the tools according to several criteria

- Segmented folding beam tools implemented

- Improved view color of the part base when importing step files

- Color marking of the selected flange in the correction menu

- Strategies without stars are no longer shown

Version 3.2.0.33089

- Clamping on hems possible with automatic calculation of upper beam clamping dimension

- Opening heights of the upper beam optimized for shorter bending times

- Calculation of bending strategies for parts with hems inside the part

- Optimized upper beam upstroke after hemming

- New gauging system configuration implemented

- Squaring arm can be selected in loading options

- Smallest stop dimension reduced from 6 mm to 5 mm

Version 3.1.7.31782

- Additional blank development for radius tools implemented

- Parameters added to Office software

- Shift of the bend line for radius tools improved

- Webserver: additional XML messages implemented

- New upper beam tools implemented

- New lower beam tools implemented

- Backgauge with brushes and w/o squaring arm implemented

Version 3.1.7.31597

- New upper beam tools implemented

- Upper beam opens at the end of a program (without considering the part's center of gravity)

- Software considers a shift of the bend line when using radius tools

Version 3.1.6.30564

- New bending strategies for profiles implemented

- Upper beam opening heights optimized

- Foot switch acknowledgments reduced

- Strategy selection for parts with "flips" improved

- Strategy selection for profiles with Z-bends improved

- Factor adjusted for blank calculation

- Material-specific blank calculation implemented

- Stop fingers remain in position control

- Min. stop dimension changed to 6 mm

- When flipping the part, the stop fingers remain in up position

- Part input extended by table input

- Number of shown table lines extended

- Input dialog for table input improved

- Sheet thickness for US market adjusted to "gauge"

- For new parts without material specification "steel" is set

- New upper beam tools implemented

- New folding beam tools implemented

- New stop configurations for 2.5 m and 3 m machine models

Version 3.1.05.29368

- New upper beam tools implemented

- New folding beam tools implemented

- New bending strategies for profiles implemented

- Input of negative angles in the dialog is no longer possible

- New gauging system configurations implemented

- Calculation blank dimension for different materials implemented (when importing STEP files the inside bend radius will be set to 1x sheet thickness)

- Field for radius input hidden

- Scale on the beams is shown in the simulation

Version 3.1.4.28164

- New upper beam tools implemented

- Closing of hems improved

- Swedish and danish language implemented

- Gauging system with brushed implemented

- Machine configuration menu extended

Version 3.1.3.27878

- New upper beam and radius tools implemented

- T-shape gauging system implemented

- Minimum sheet thickness set to 0.5 mm

- No folding beam adjustment within a program. At the beginning of the program the maximum required folding beam position is set.

- Texte bei Biegen von Umschlägen im manuellen Modus angepasst

- Texts adapted when bending hems in manual mode

- Dutch language

- Office version: Machine configuration menu implemented

Version 3.1.2.27441

- Editor for customized bending sequence implemented

- Hemming in the editor with separate two steps: pre-bending - closing the hem

- Hemming position adapted to tools

- New step bending interface for radii bending incl. correction tables

- Speed Optimizer: Opening the upper beam after the folding beam is <90° and the part's center of gravity is inside the machine

- When creating a part: visible side outside

- Bending angle shown positive/negative according to the bending direction

- Configuration "sheet thickness unlimited" implemented (example: bending of plastic material)

- New upper beam tools implemented

- Machine models adapted to modified machine design

- TURBO2plus RAS 62.25-2 implemented

- Improved part representation in the simulation

- Adjusted columns in the part selection

Version 3.1.0.25172

- Standard material thickness set to 0.5 mm

- Profileditor for the input of part profiles

- Upper beam tool 40V implemented

- Folding beam CrownTool implementiert

- Indication of folding beam adjustment

- Material tables added (without negative angles)

- Gauging at obtuse angles

- Stop finger support while closing hems

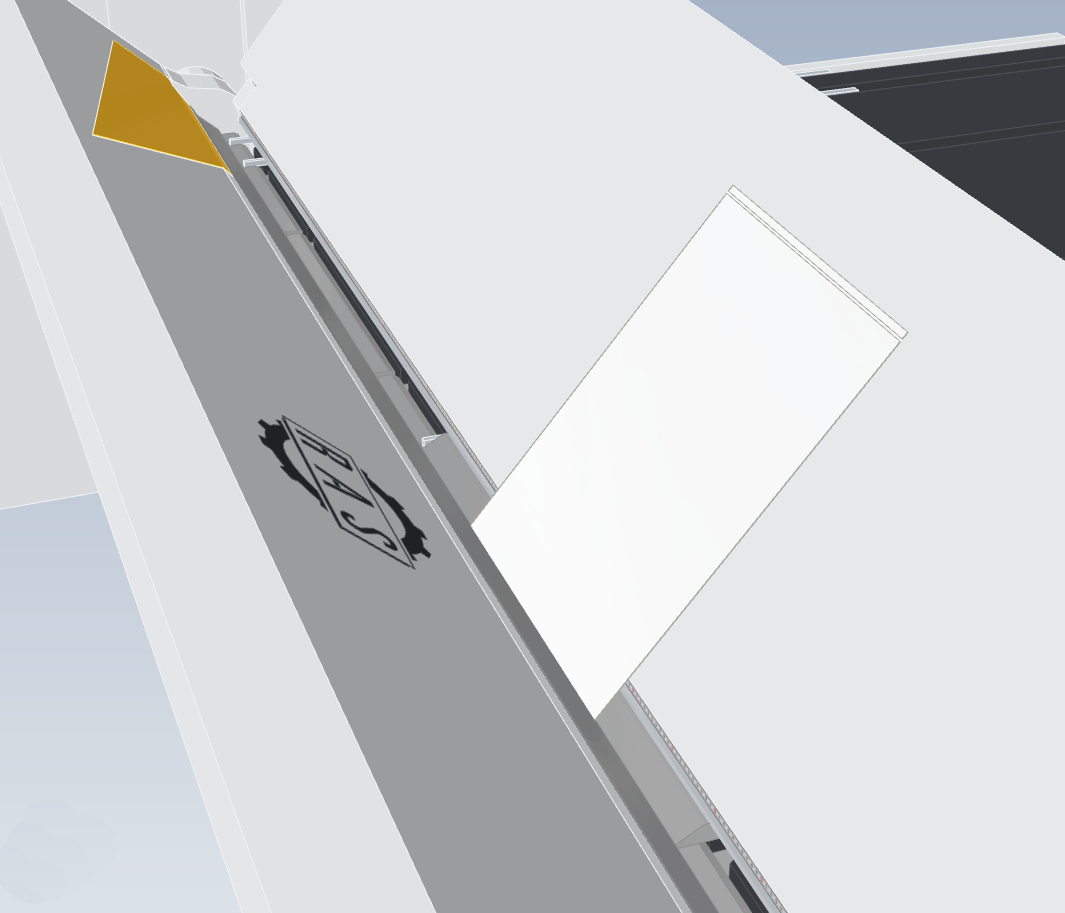

![[Translate to english:] Schmale Biegeteile mit nur einem Anschlagfinger positionieren [Translate to english:] Schmale Biegeteile mit nur einem Anschlagfinger positionieren](/fileadmin/user_upload/Ein-Anschlagfinger.jpg)

![[Translate to english:] Während des Biegeablaufs wird die Schnittdarstellung angezeigt [Translate to english:] Während des Biegeablaufs wird die Schnittdarstellung angezeigt](/fileadmin/user_upload/Querschnitt_Biegen.jpg)