Intelligent control

The intelligent RAS EasyFormer-3 swaging machines with AutoTeach Function "learn" from the operator how to swage and flange parts. This leads to repeatable parts of the highest quality.

- Operating modes: Teach, Automatic, Manual

- Manual: For one-time work

- Teach: When running the first part of a production lot

- Automatic: When applying the taught sequences for a series of parts

Practical functionality

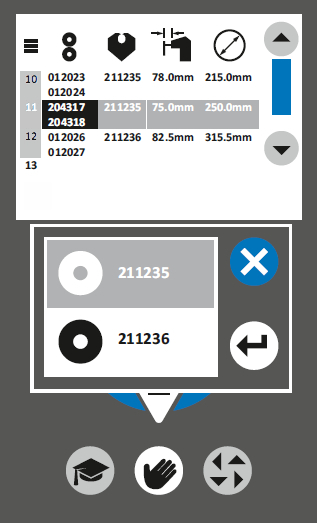

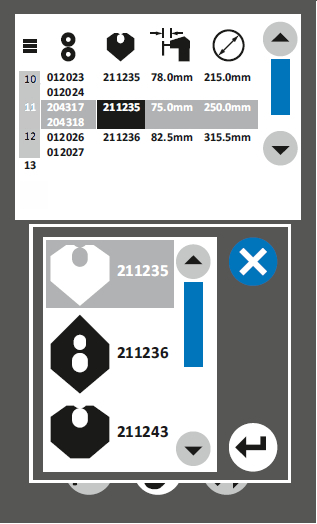

The EasyFormer swaging machines can be operated via a touch panel control. The 2-axes control automatically learns and memorizes the movement sequences from the operator. Saving and loading of standard programs takes on a whole new meaning.

- Storage and easy selection of up to 20 programs

- Clear program management menu

- If intended, the used wheels, the selected stop plate, the stop position and the pipe diameter can be stored

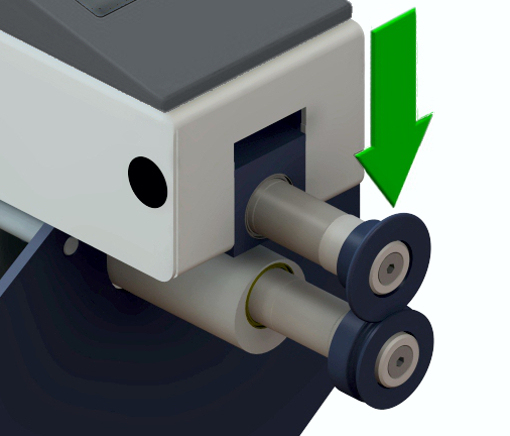

- Dimension-related setting of the upper wheel with digital display

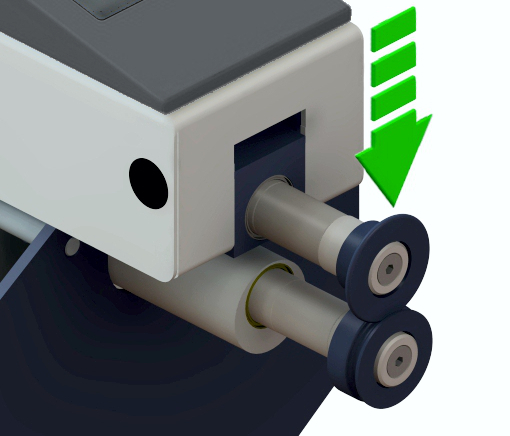

- Continuous or progressive upper wheel adjustment achieves best forming results for thin and thick materials

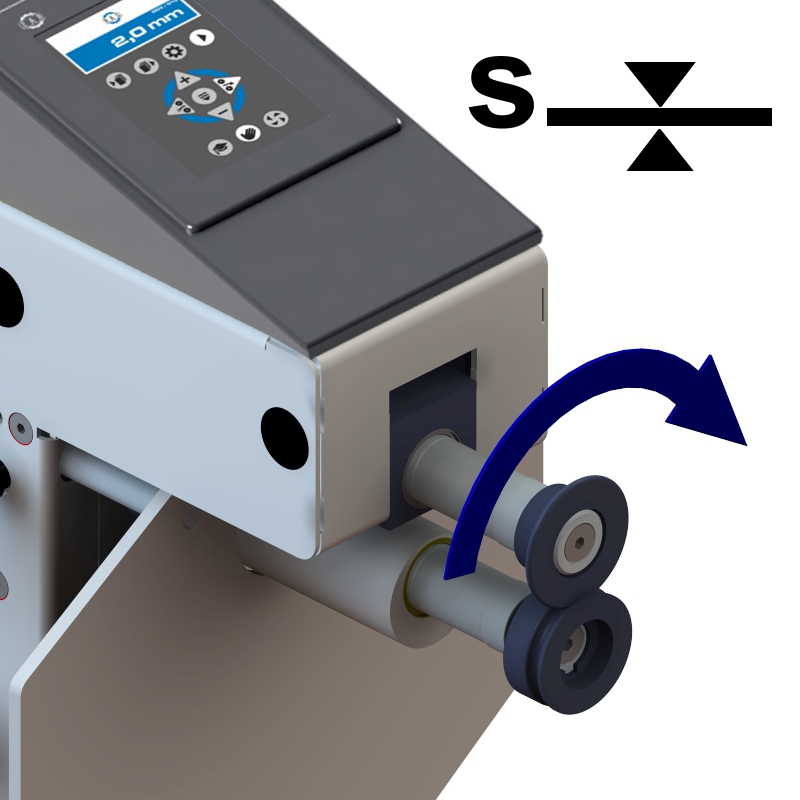

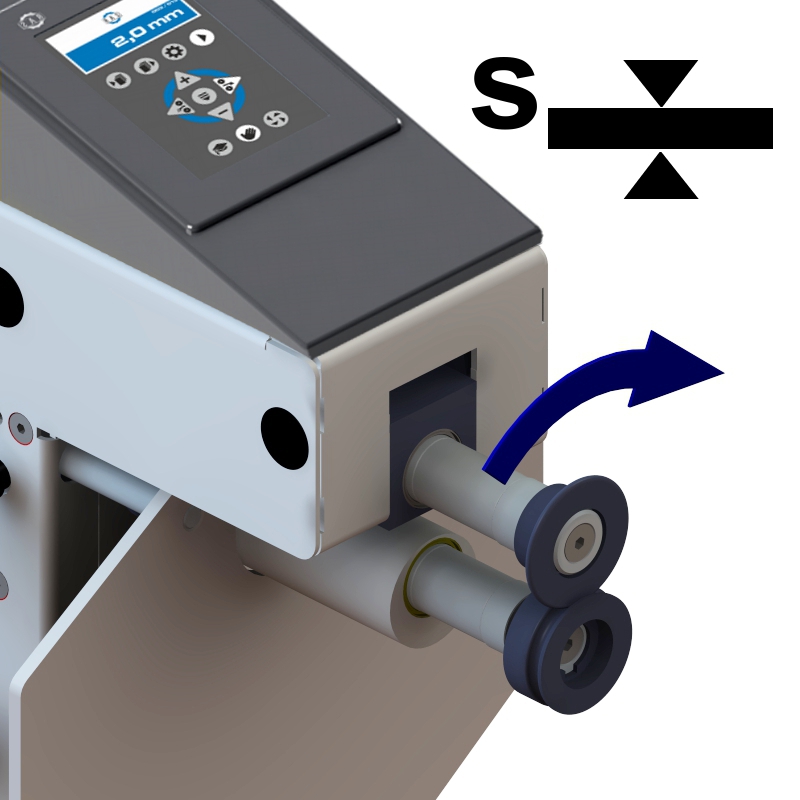

- Right-left-run

- Wheels reach their turning point in forward/reverse operation with high accuracy

- Soft speed-up and slow-down at start and at direction change

- Two speed ranges for fast or sensitive work

- mm/inch selection

Suitable stops

The high-strength and extra-large stop plate is designed for the highest demands. In addition, other stop plates are available.

- The divided stop can be used for almost all wheels

- Stop plate for insulating pipes (RAS 12.35-3 only)

- Special stop plate for bevel flanging wheels BD

- Round stop for internal flanges on blanks (RAS 12.35-3 only)

Setting made easy

A convenient hand lever allows positioning of the lower wheel, so that both wheels are precisely positioned over one other. A clamping mechanism assures that the shafts stay in position.

- Sensitively lower shaft positioning

- Positioning of the lower to the upper wheel shape

- Central shaft adjustment with lever and scale

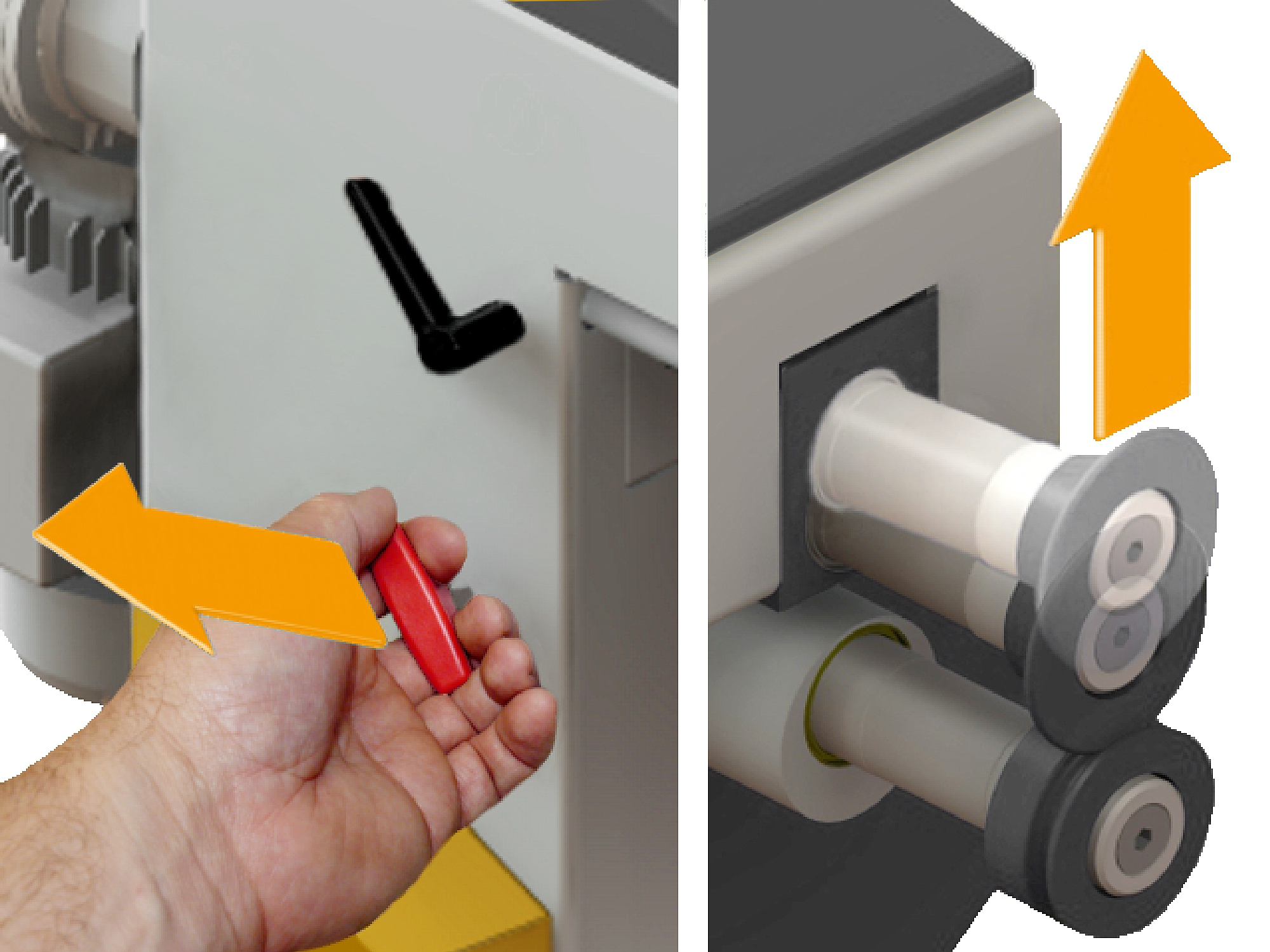

Unique UnLock safety function

If at risk, simply pull one of the UnLock levers left or right on the machine frame and the wheels open immediately.

- Mechanical shaft unlocking in case of emergency

- Quick release

- Also effective in case of power failure due to overload

- UnLock function meets the highest safety standards

Versatile operation

The multi-function foot switch can be configured. Thus, the machine follows the operation preferences of the worker. The foot switch can perform one of the following functions:

- Right-left run

- Continuous upper wheel adjustment

- Progressive upper wheel adjustment

- Advantage: The operator can always guide the part with both hands