Maximum productivity

Speed in all aspects of operation ensures high throughput and productivity:

- Rapid sequence of up to 50 strokes per minute

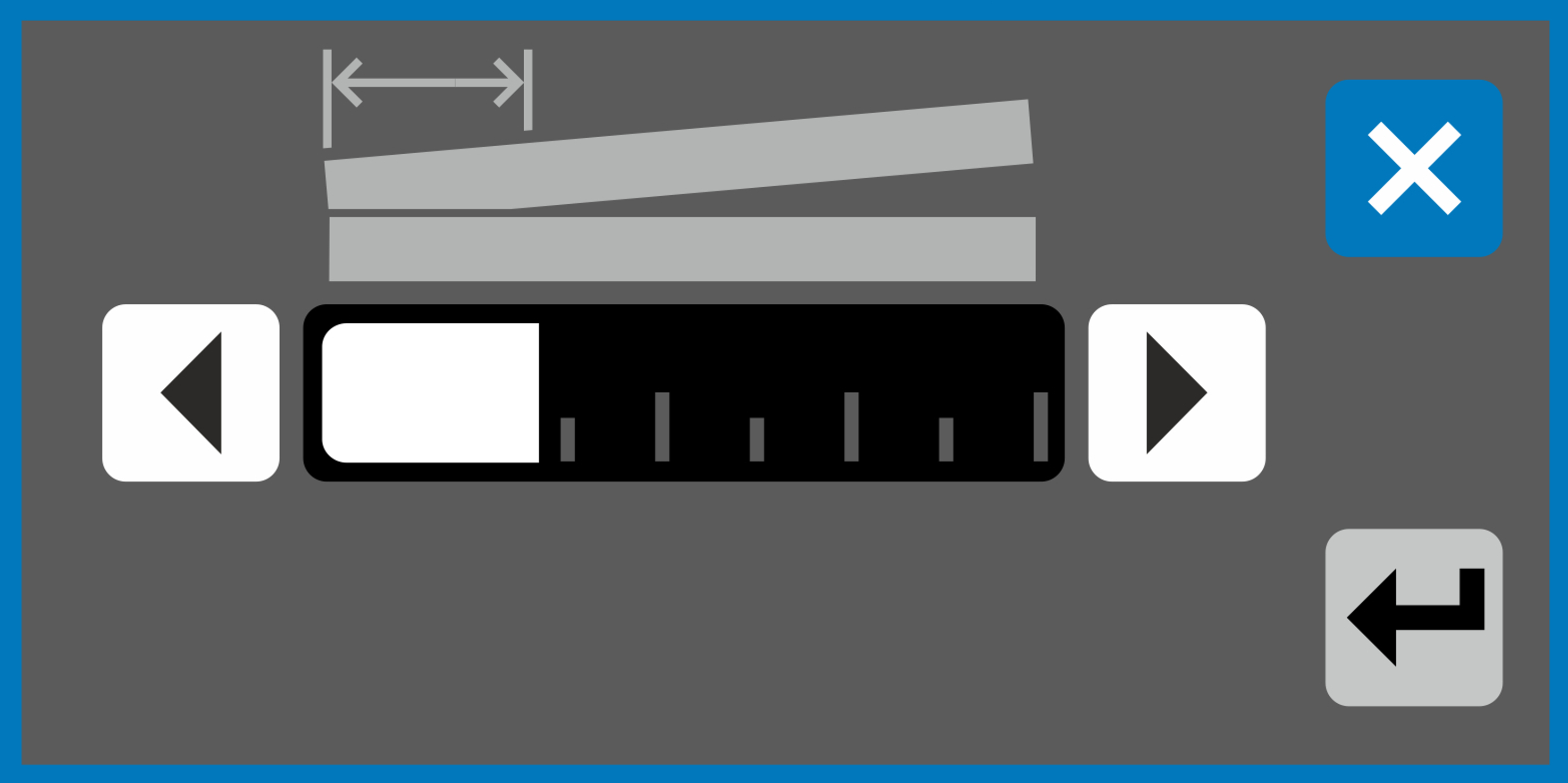

- Adjustable cutting length for short parts

- Fast backstop movement

- Fast and automatic blade clearance adjustment

- Sorting functions of the sheet support and sorting system

- Single stroke and continuous strokes

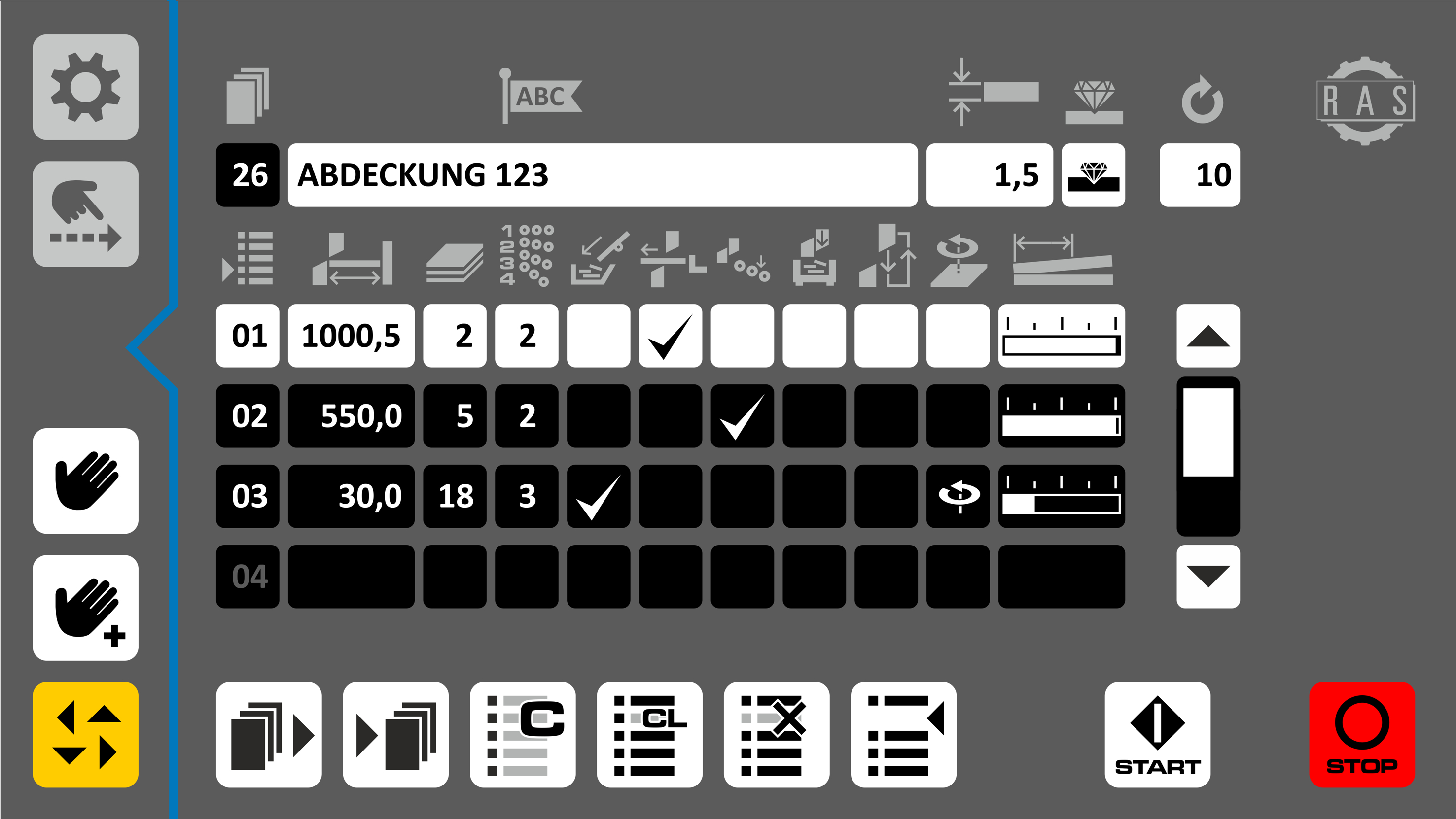

Individual operating concept

The 15" touch monitor offers maximum and individual operating convenience

- Large screen and purely icon based operating functions

- Simple, fast and intuitive inputs

- Movable control panel along the front of the machine

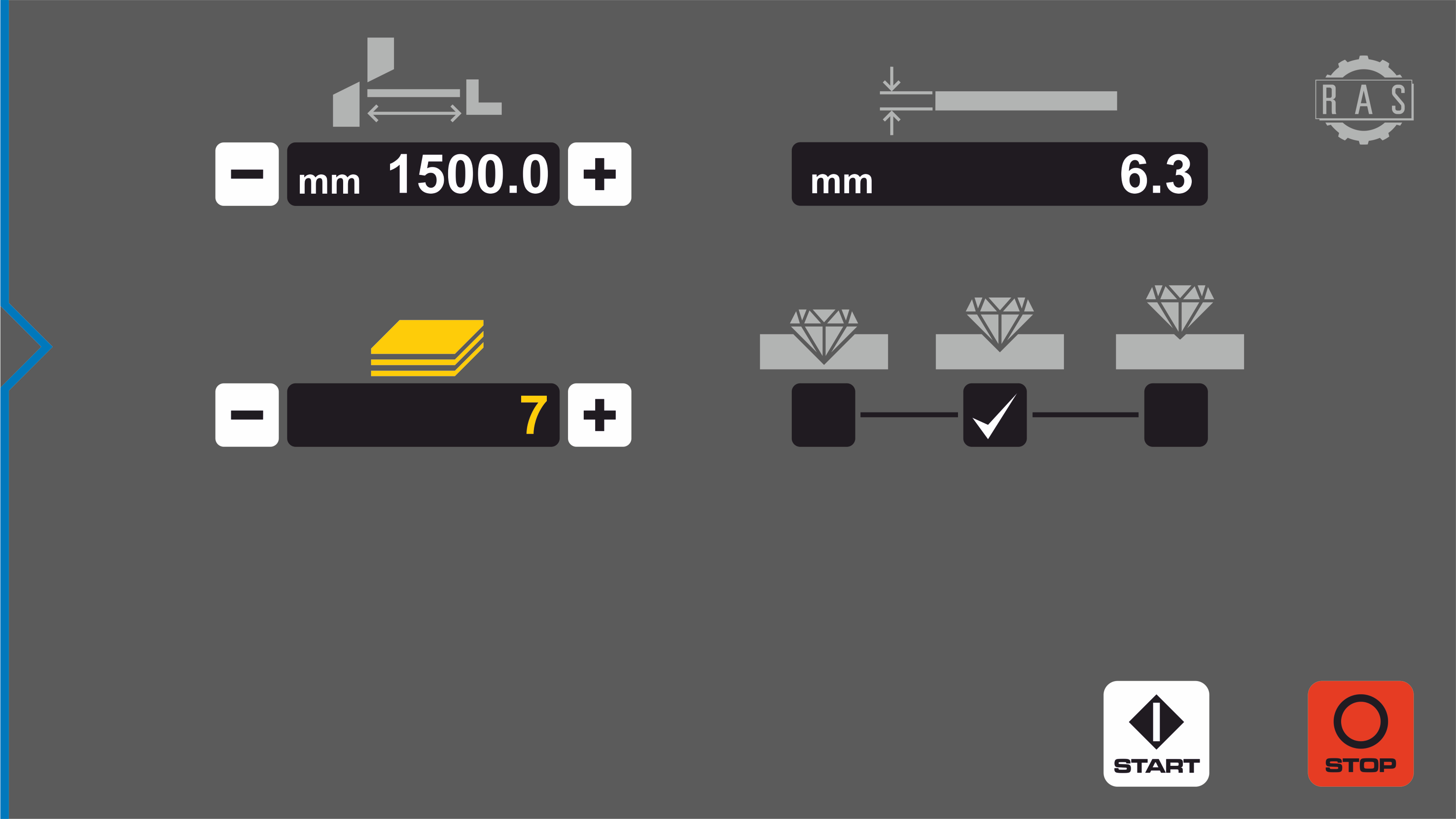

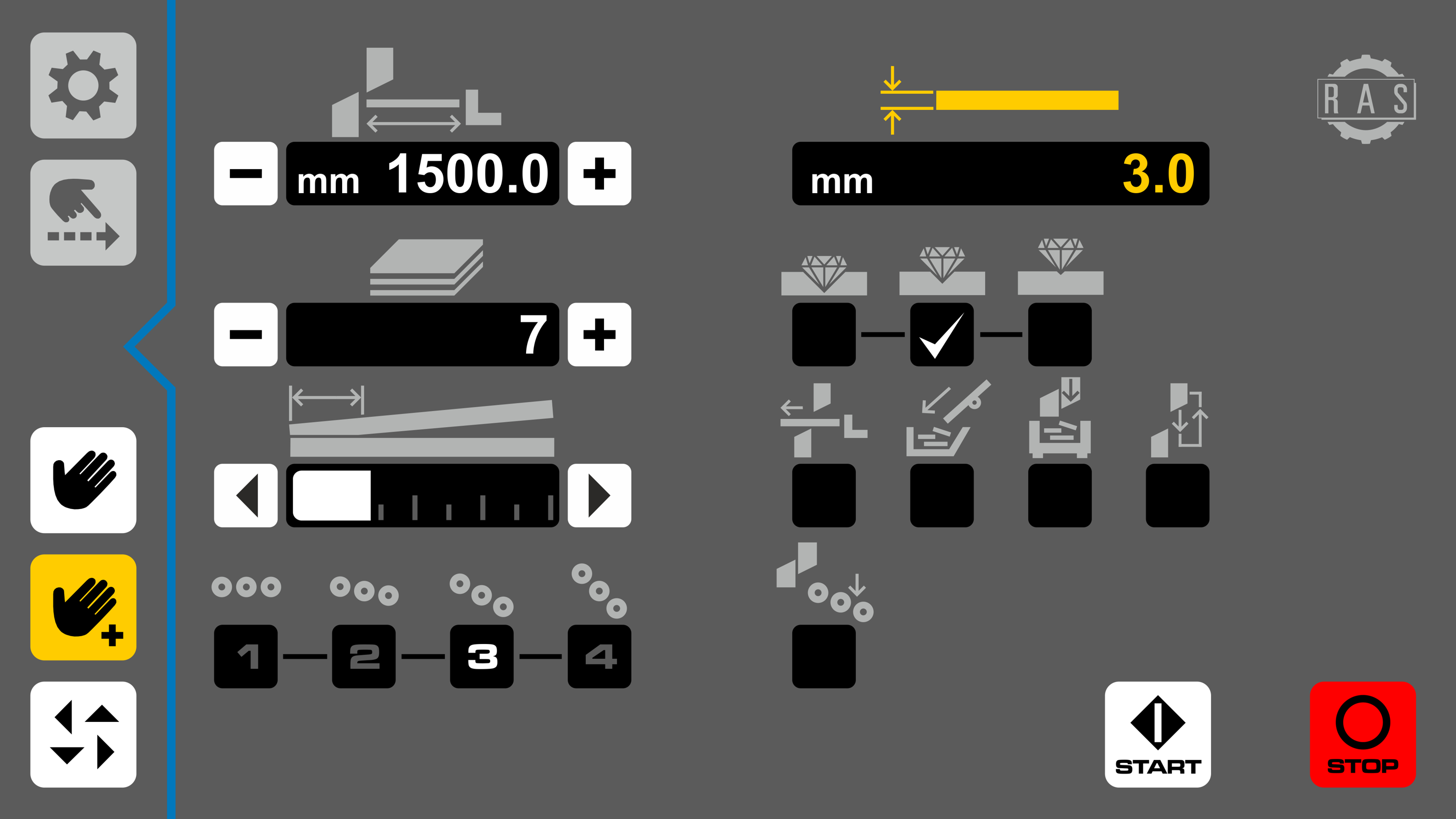

- 3 operating modes for occasional users, more experienced users, experts

- Simple mode: sheet thickness, material type, stop dimension and quantity

- Advanced simple mode: additional sorting functions and cutting length

- Program mode: Cutting programs with several program lines

- Save and load programs

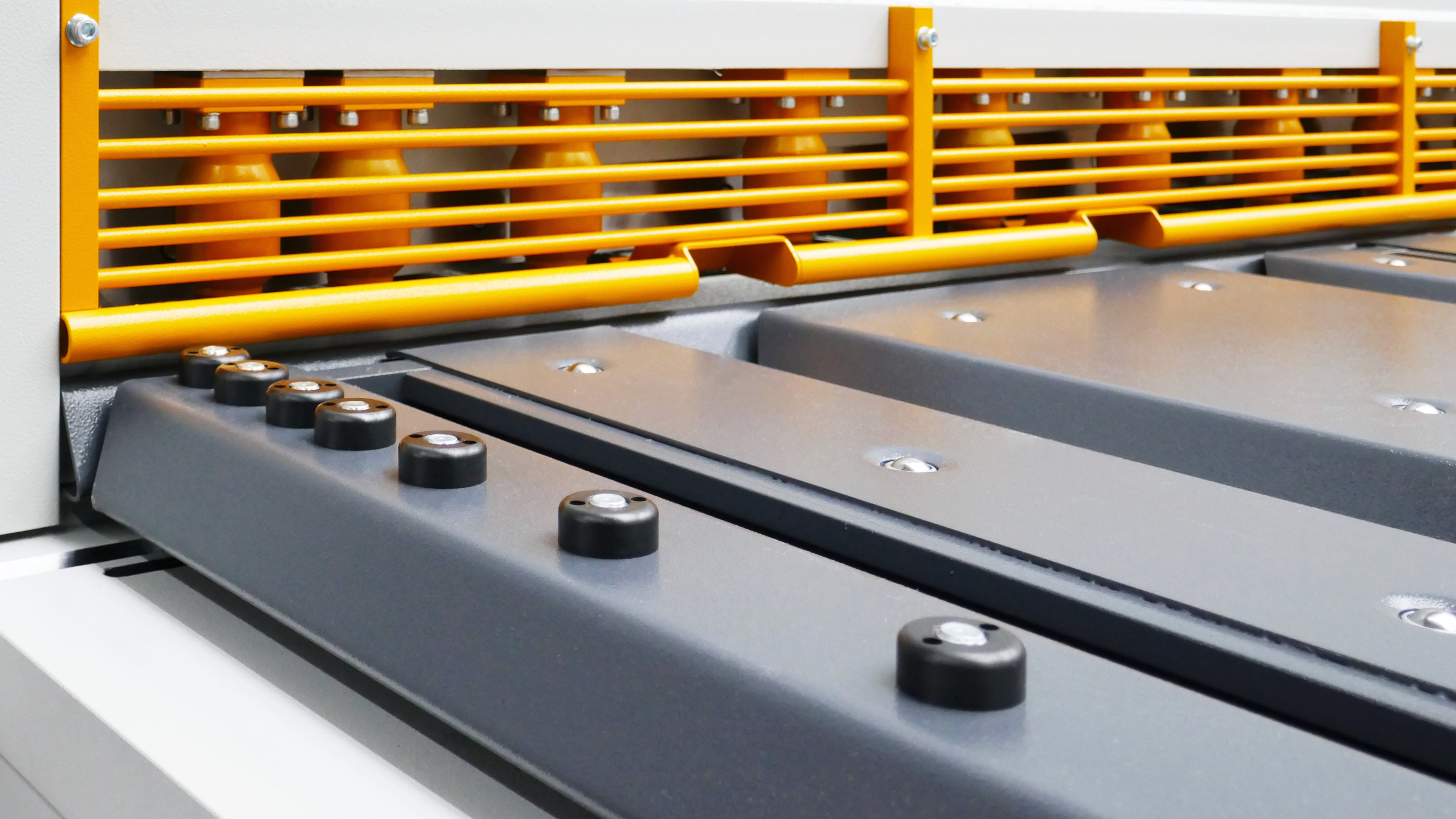

Best operator ergonomics

The shear table is the operator's direct working area. Its design ensures for easy, quick and efficient material handling.

- Working height 850 mm

- Wide, beveled and rigid tables for quick material handling

- Ball rollers for gentle metal plate movement

- Recessed grip between shear tables

- Table extensions and table supports for easy access

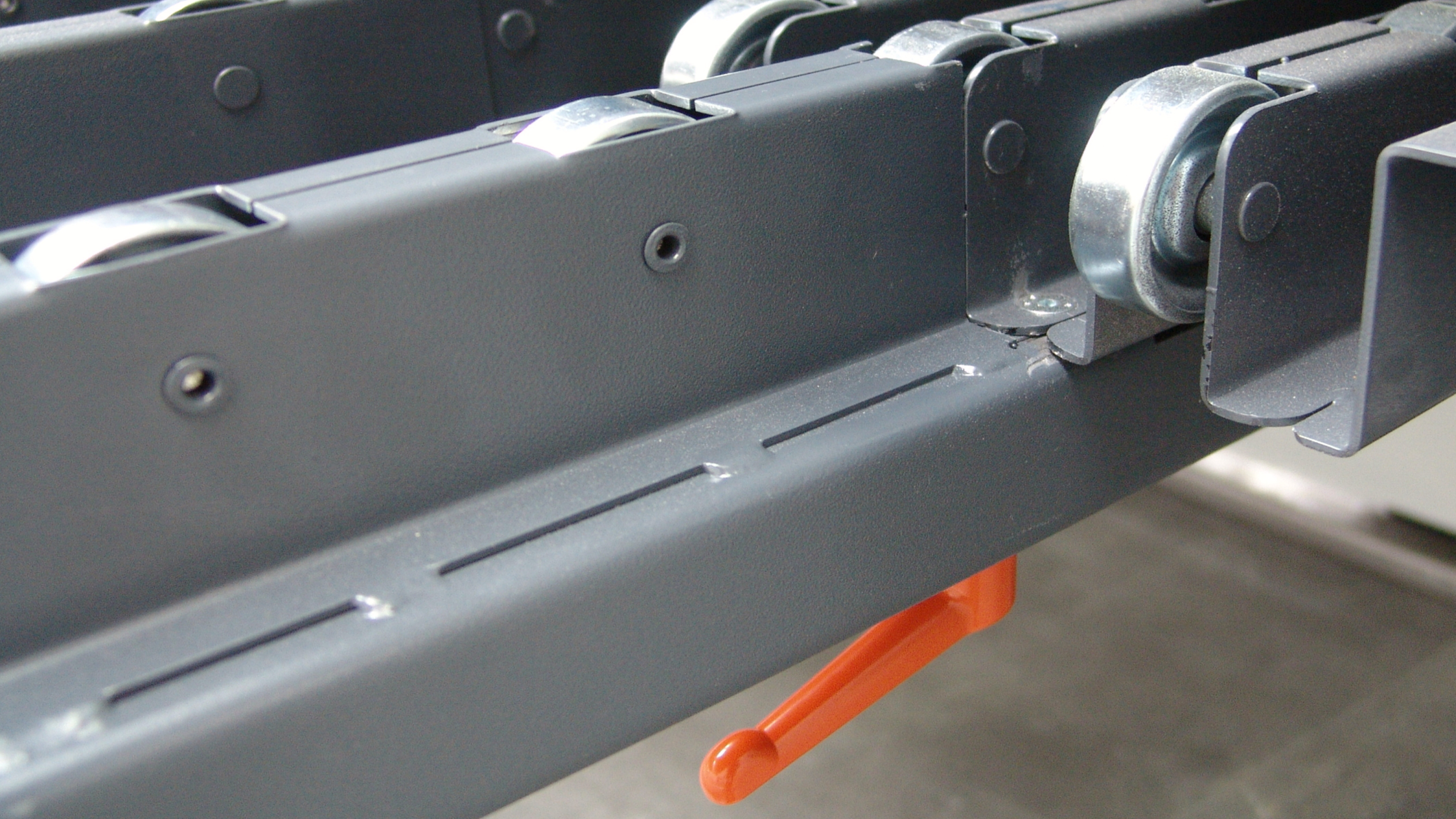

- Moveable table extensions can be added within seconds

- Table extensions can be easily docked with a lever

- Front stop with fine adjustment

- Adjustable and self-cleaning squaring stop

- Finger safety protection with good visibility

- Deep finger pockets for an optimum material use

- LED workspace illumination

- Hold-down pressure automatically adjusts for slip free cutting

- Easy maintenance and good accessibility when changing the oil

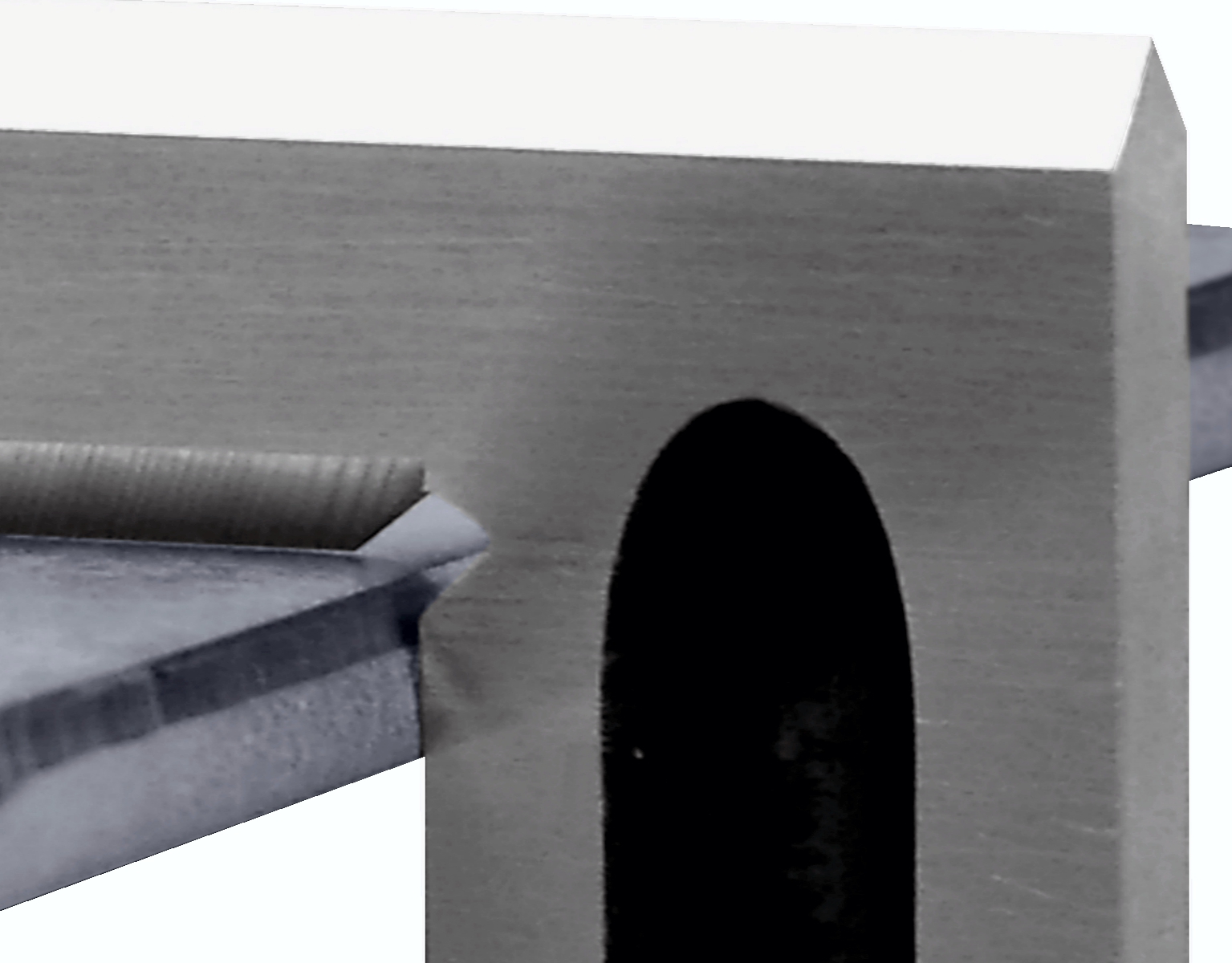

- Large frame cutout for easy blade change

- Highest safety levels by two-channel queries

Precise cutting dimensions

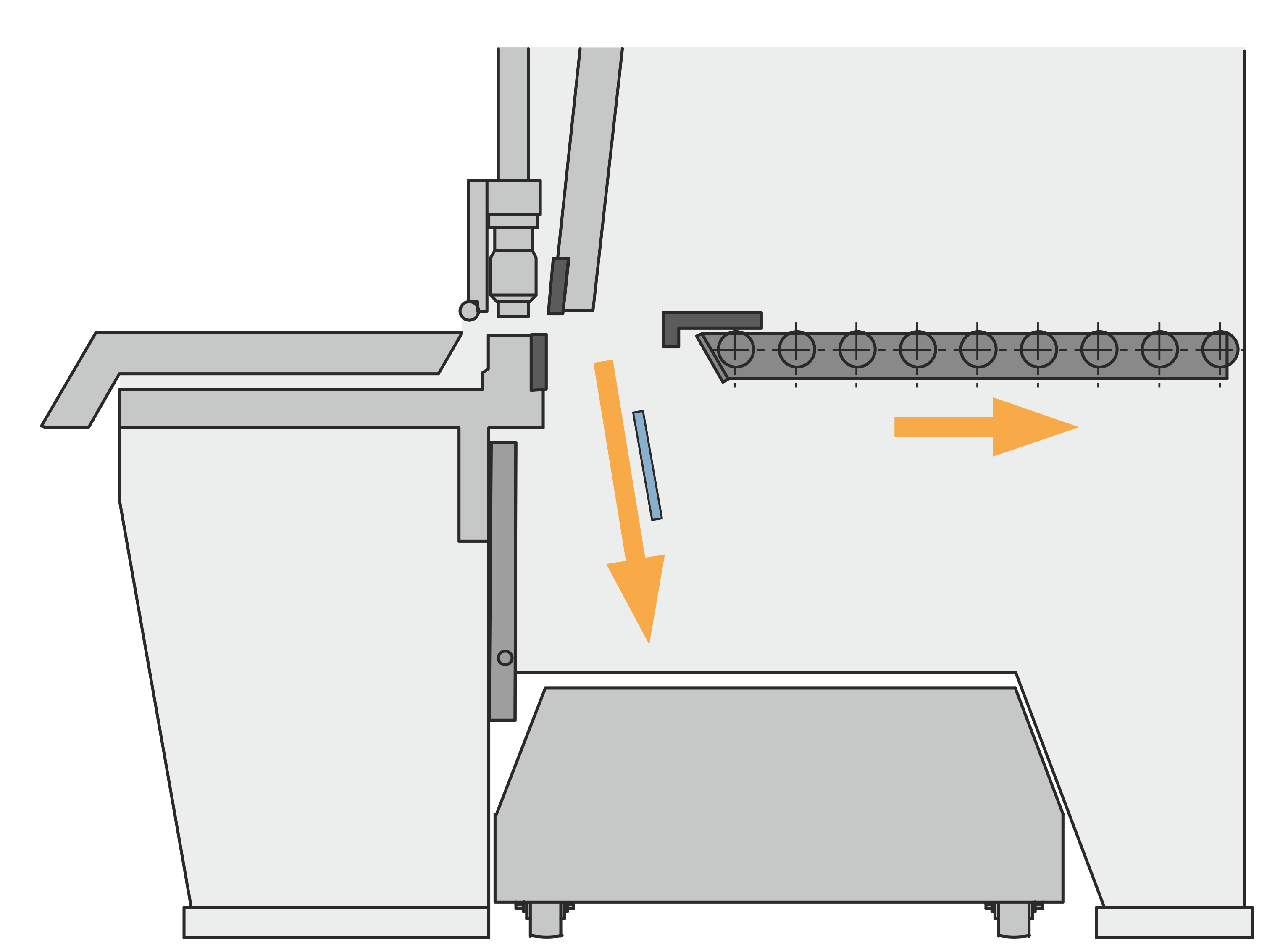

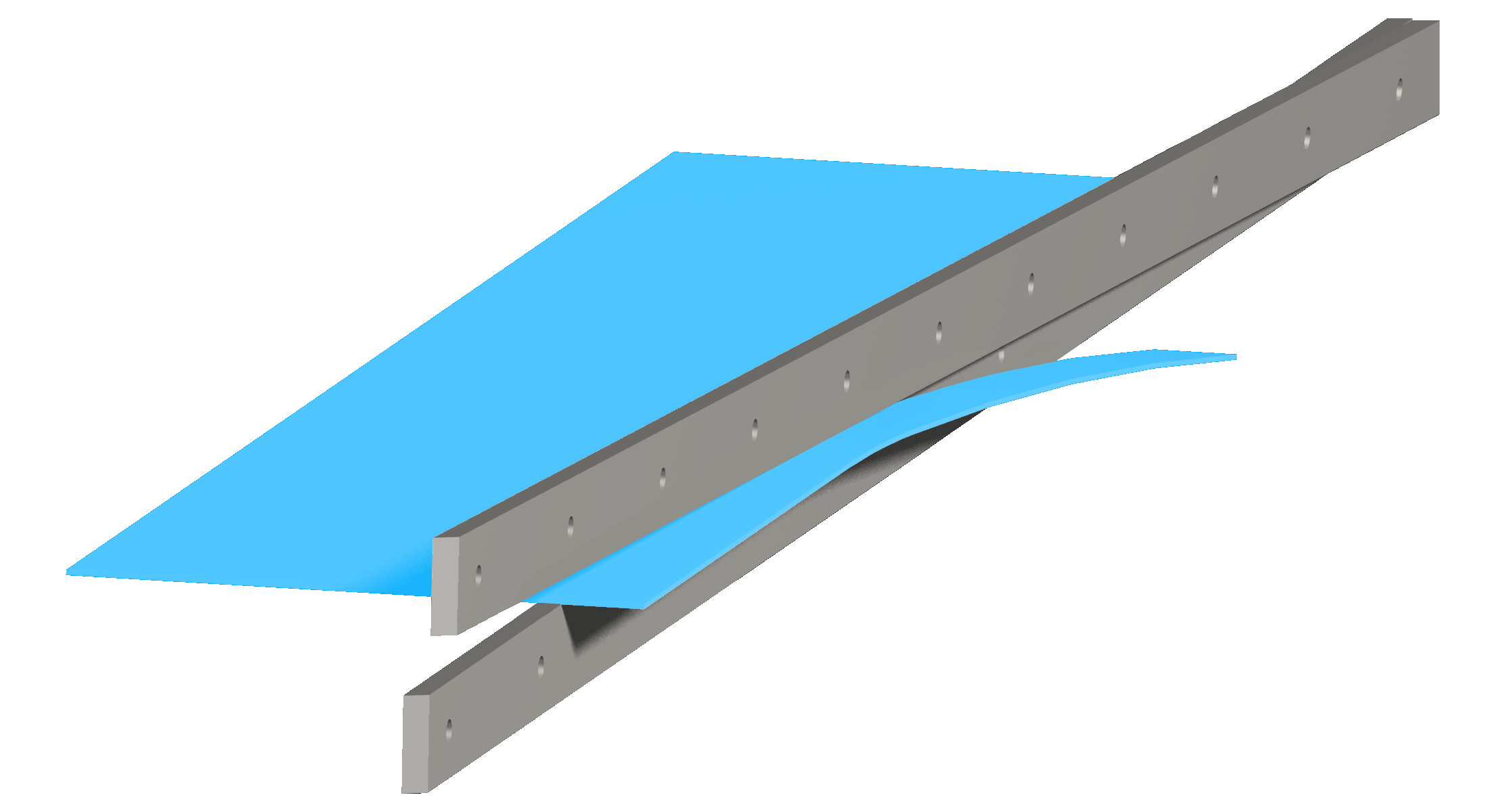

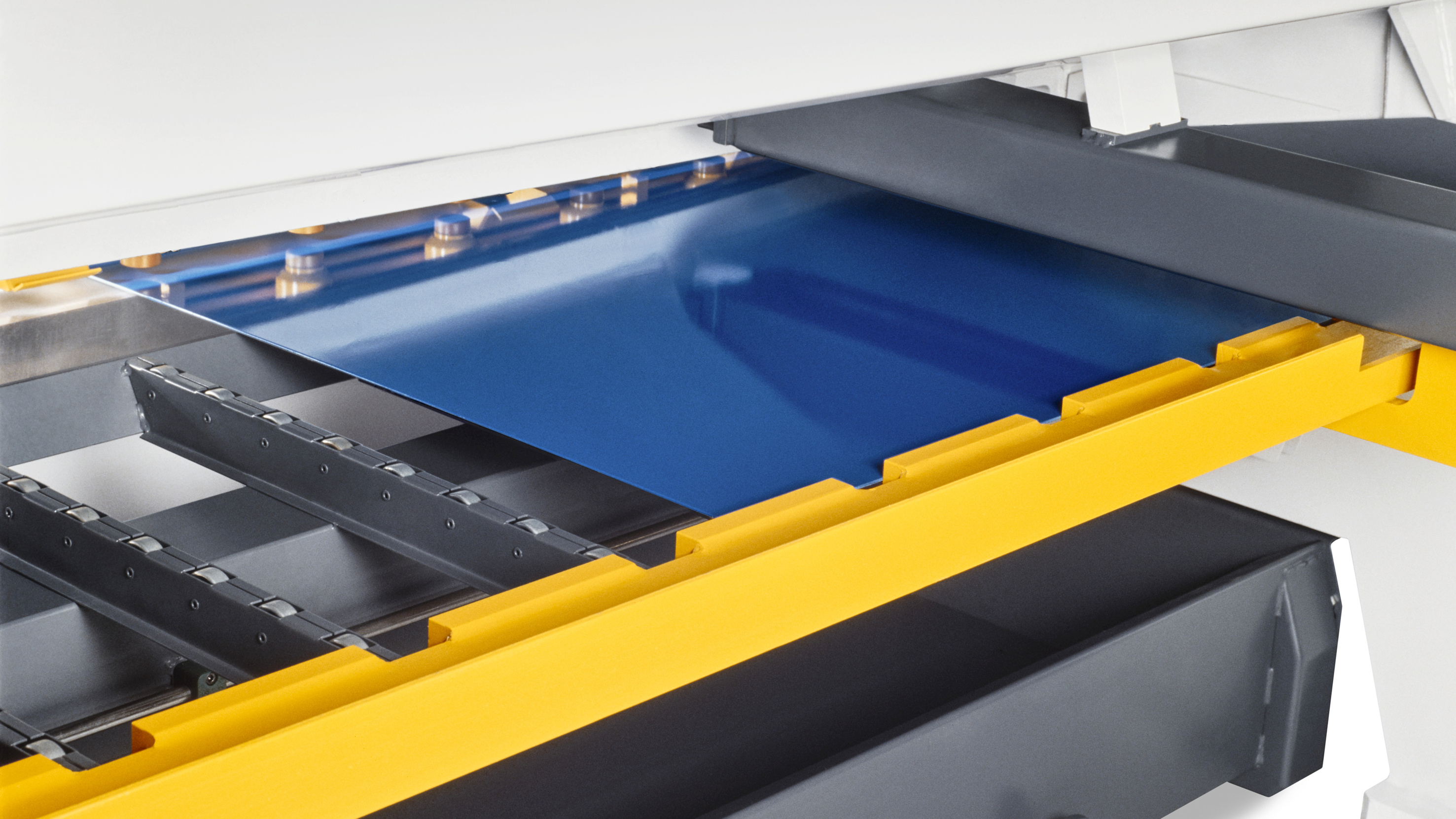

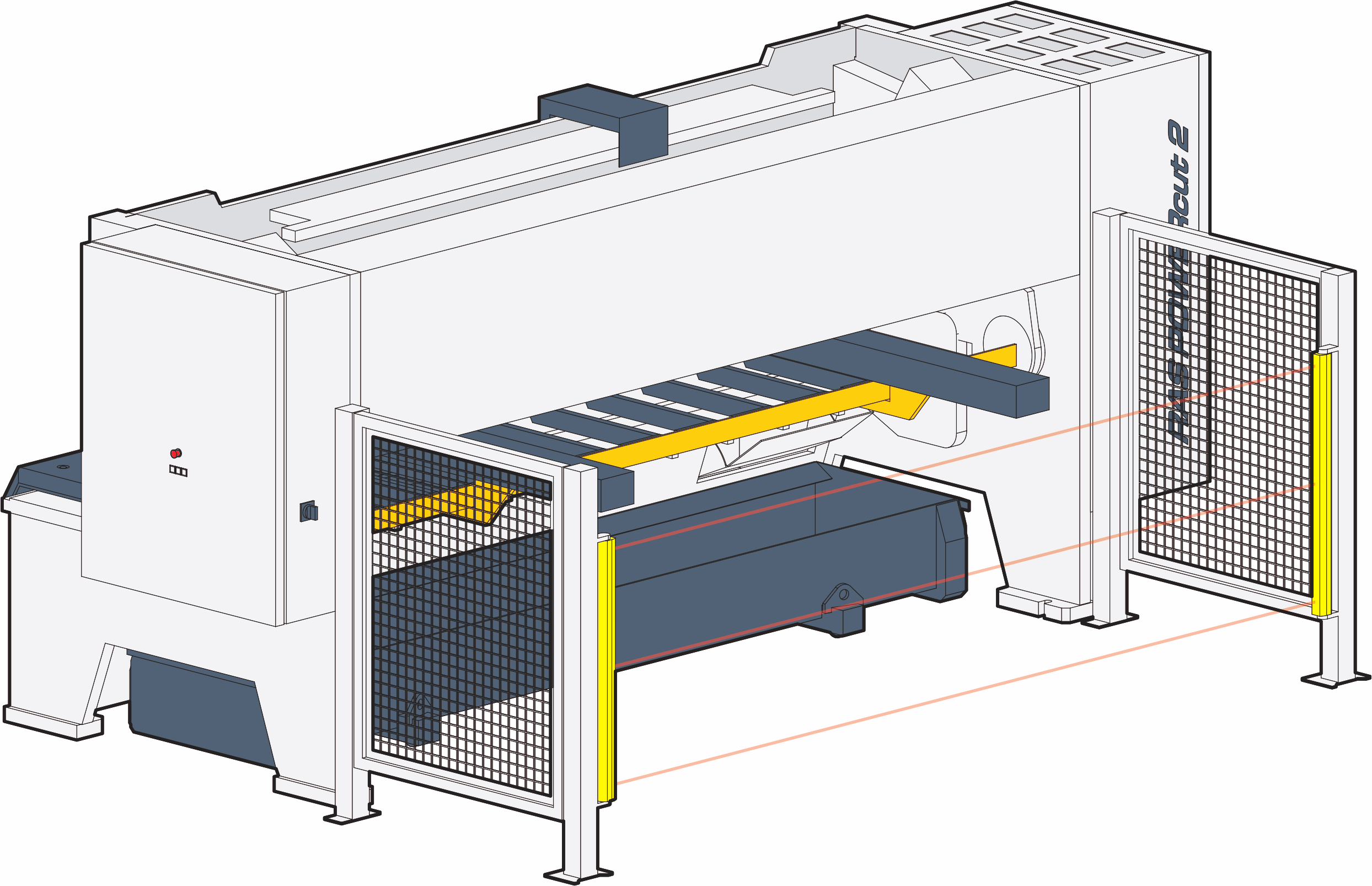

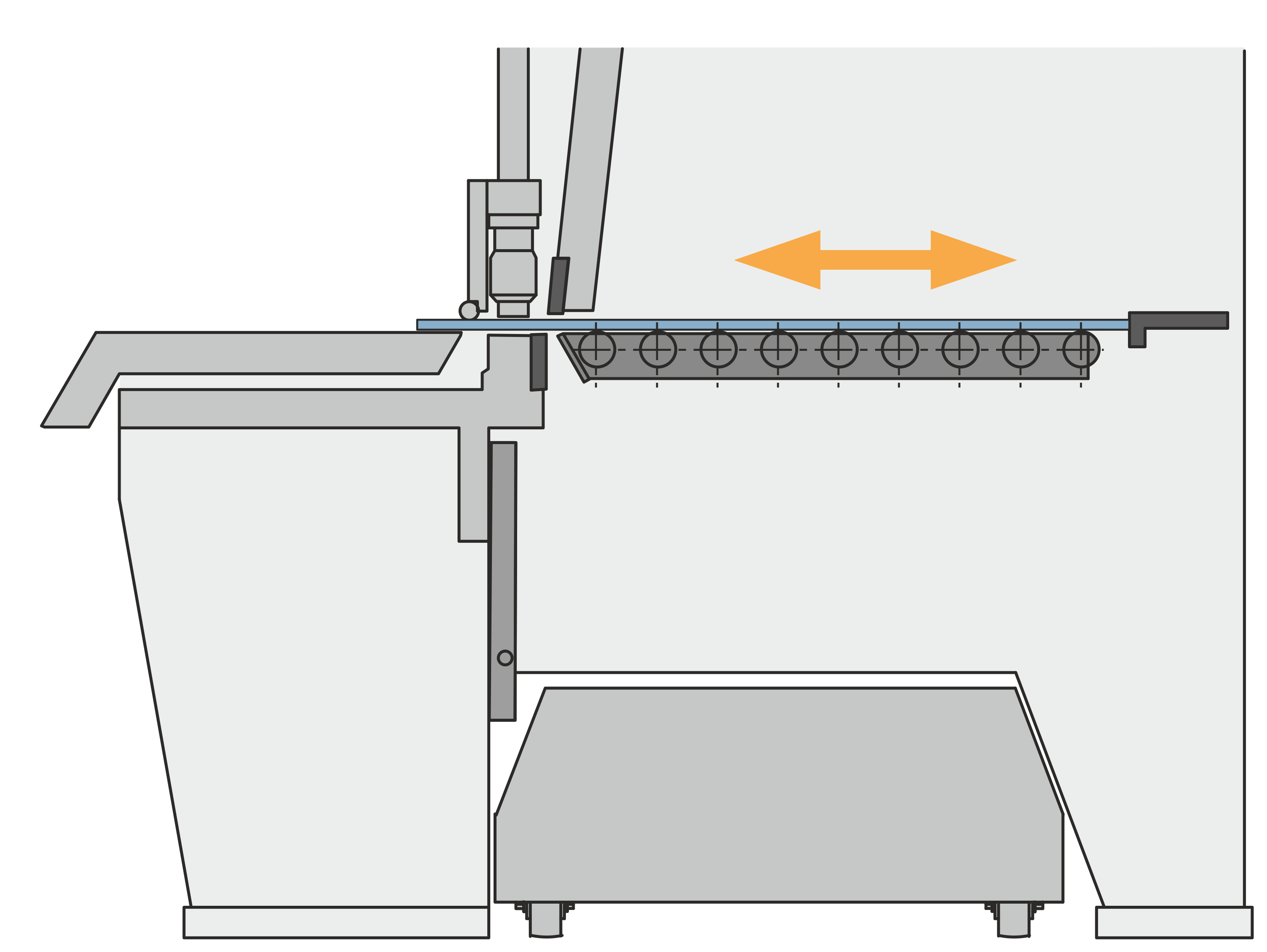

The combination of CNC backstop and sheet support system ensure precise cutting dimensions. The sheet support system guides the sheet to the backstop.

- Sheet in a horizontal position: exact cutting dimensions

- Backstop depths selectable: 1000 mm, 1250 mm and 1500 mm

- Snap-on extensions of the sheet support arms

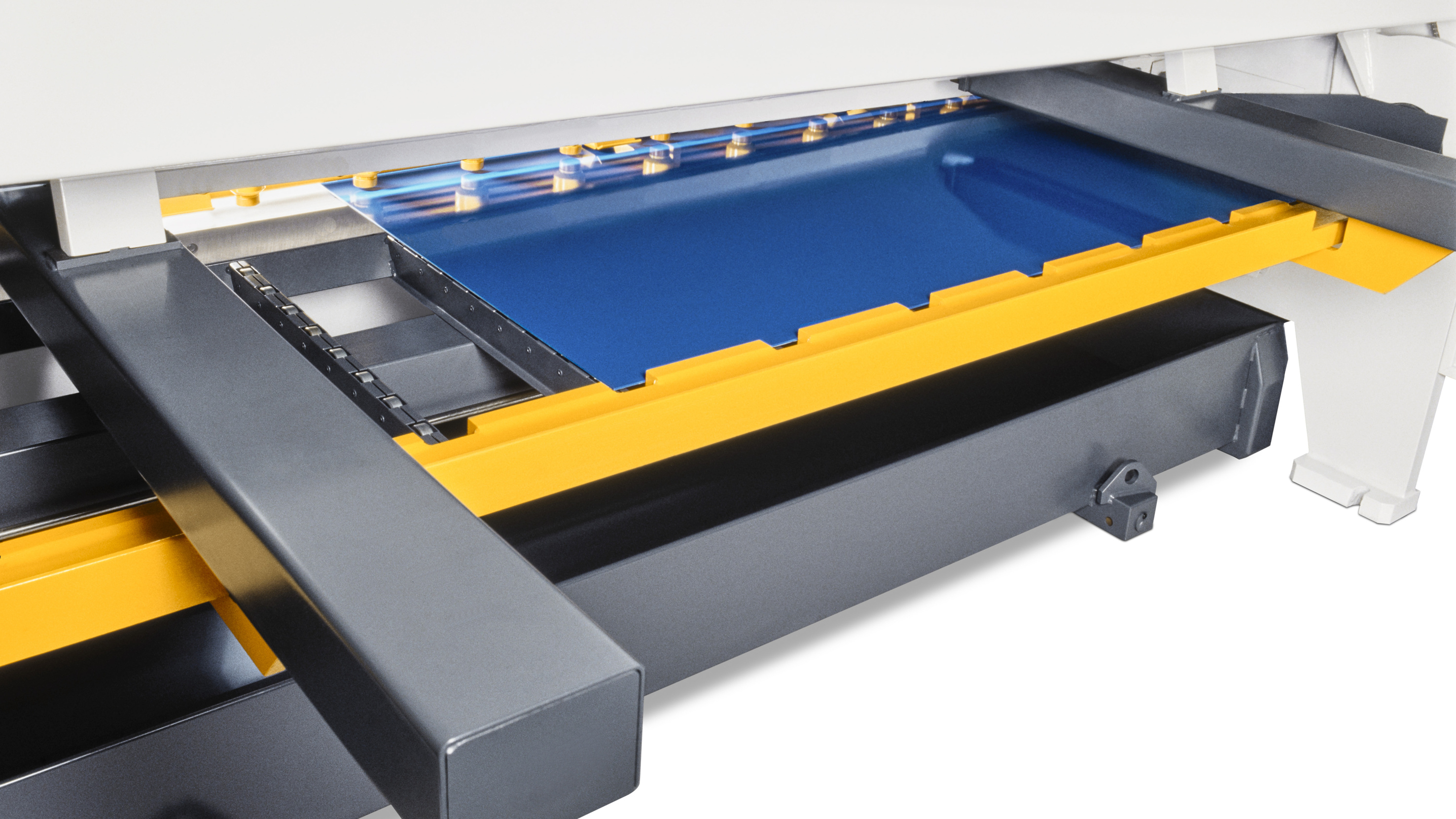

Sorting while cutting

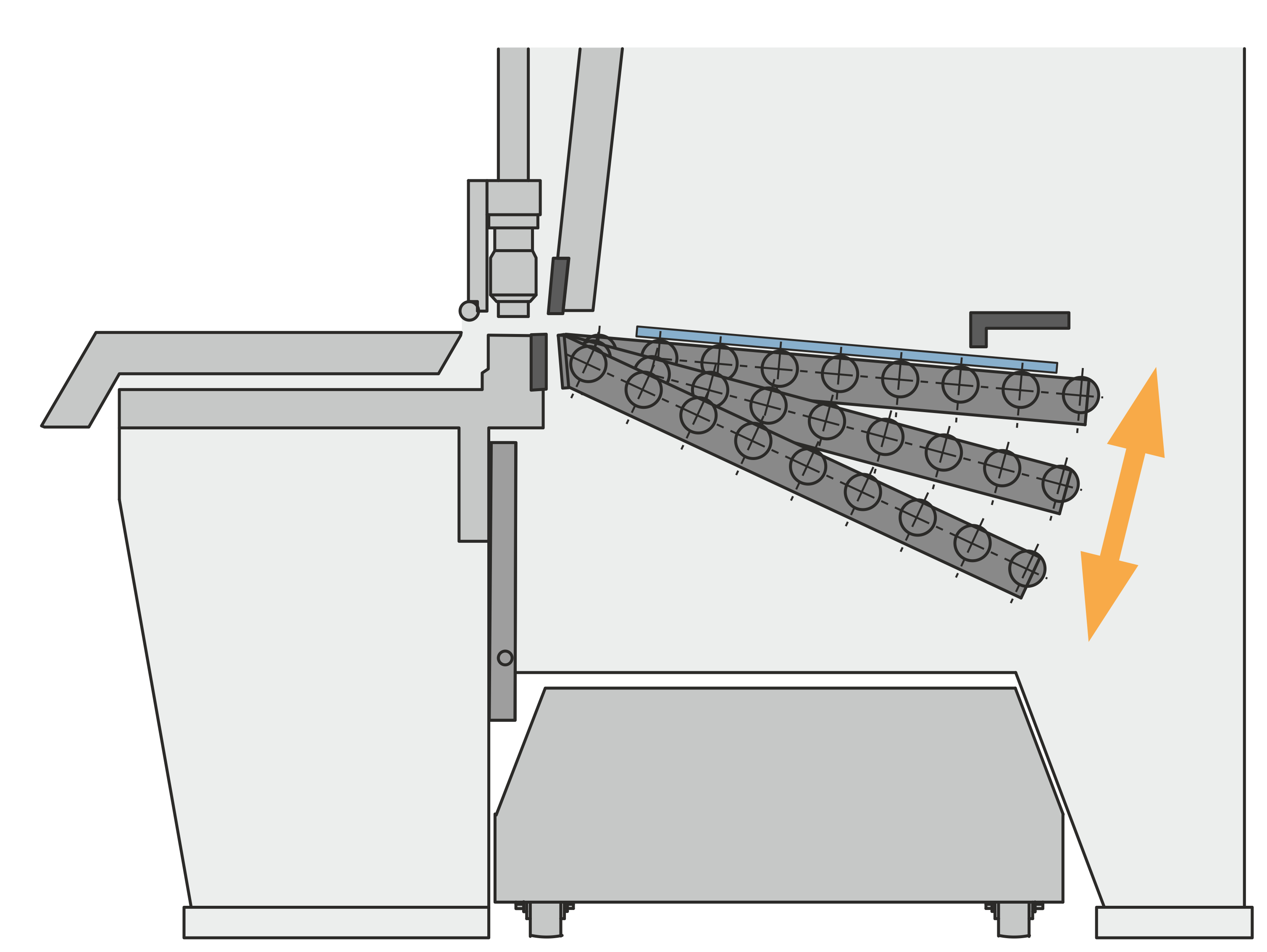

After the cut is made, the sheet support system shows its superiority with multiple material sorting functions:

- Sorting the blanks while cutting increases productivity

- Blanks rolling off in 3 angular positions

- Low angle for sensitive parts: smooth and gentle delivery

- Steep angle for normal blanks: fast delivery, rapid sequences

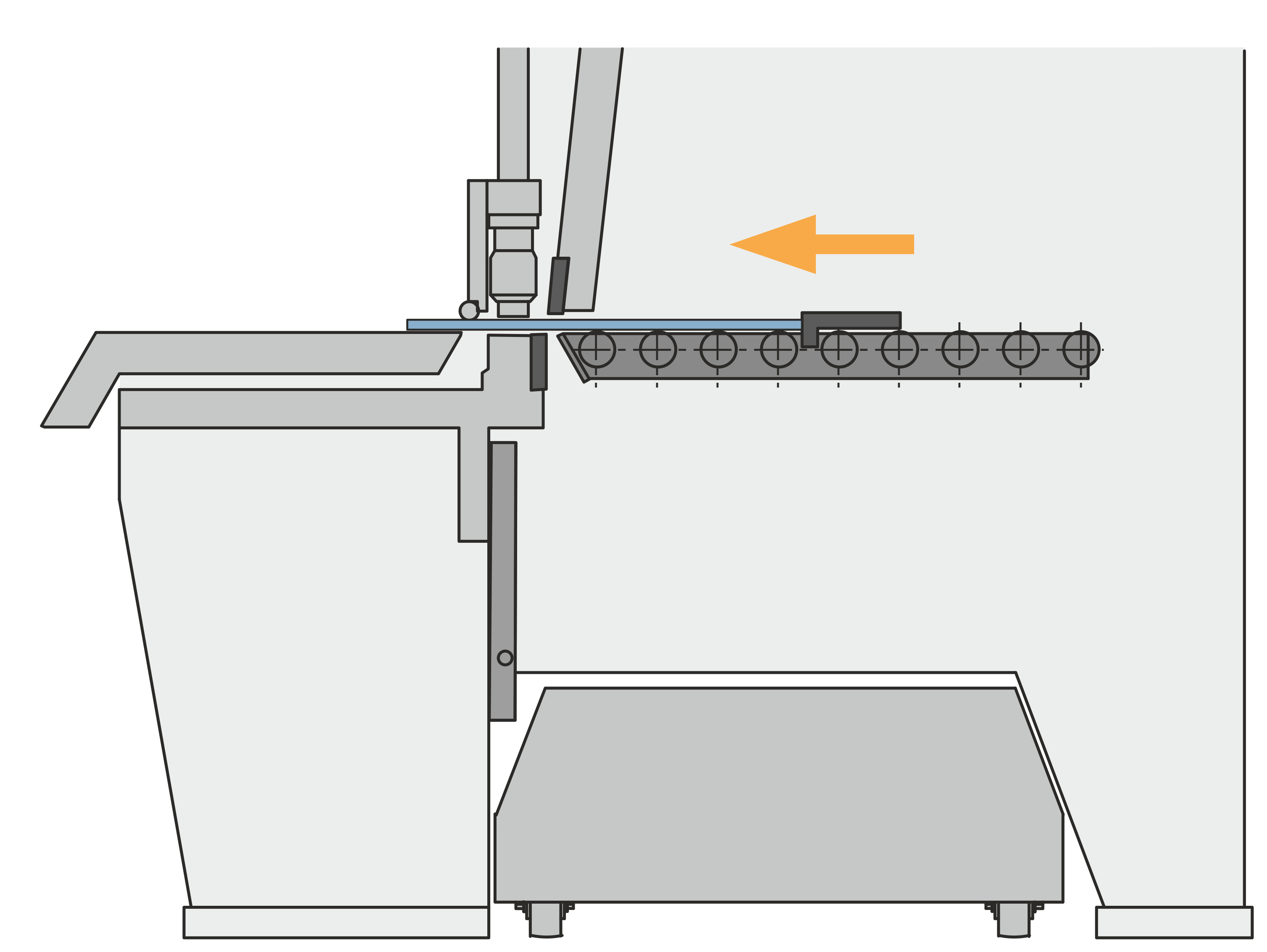

- Return-to-Sender brings cut parts back to the operator

- Safe small parts sorting to the front (max 200 x 500 mm)

- Trim cuts fall into large volume scrap box

- Separation of good parts and scrap during cutting

- Removal of full scrap box to the rear, the right or the left

- No material sorting required below the shear

![Small parts sorting to the front (max 200 x 500 mm)en Behälter vor der Schere geleitet [Translate to english:] Trennen von Großteilen und Kleinteilen schon beim Zuschneiden](/fileadmin/user_upload/86xx_Kipproll-Funktion_04.jpg)