Durable machine table

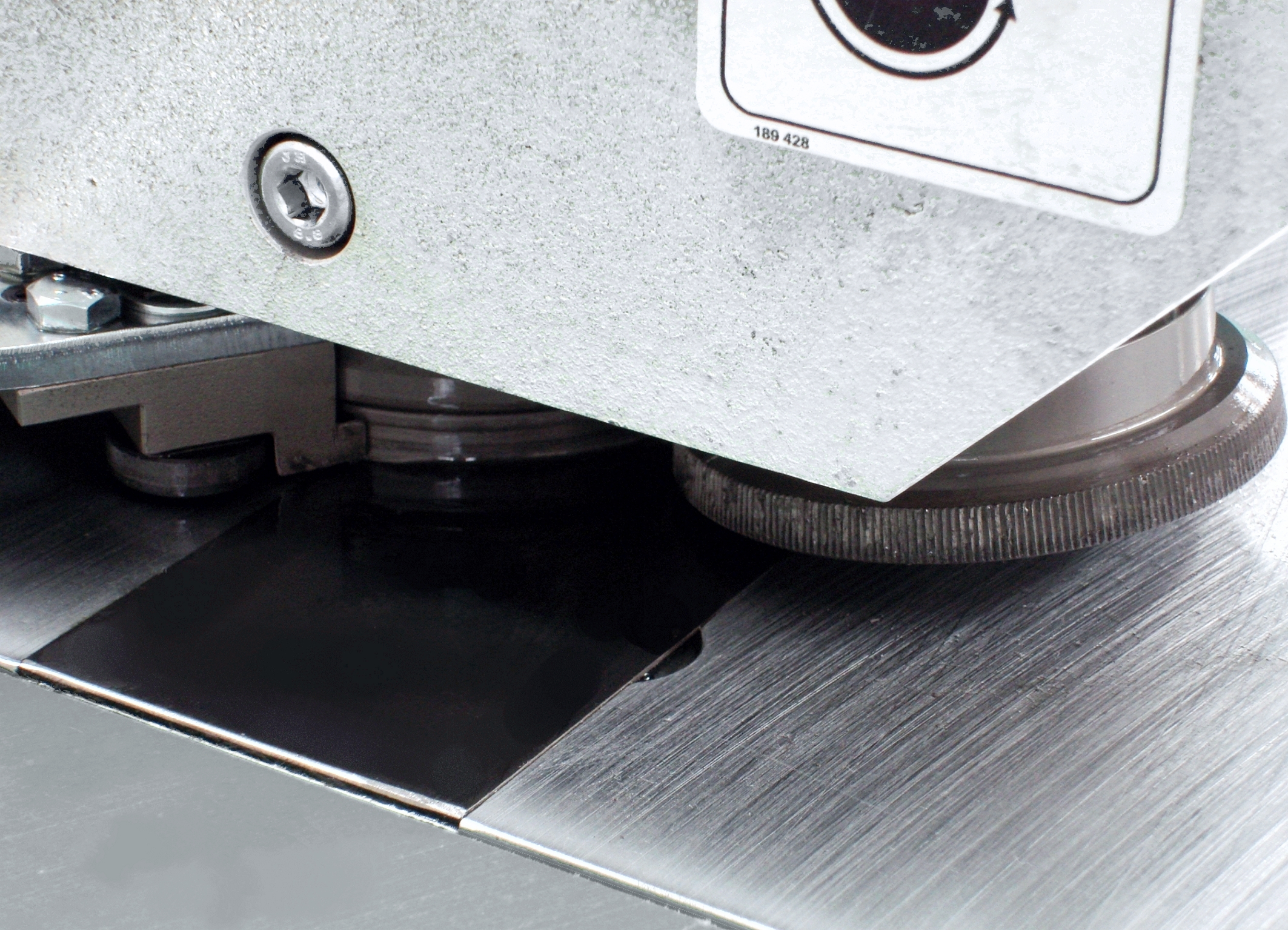

The wide support surface at the run-in and run-out side of the machine supports the air duct components. A wear-resistant pressure piece at the forming point ensures the long lifetime of the forming station. An additional spring steel insert in the table plate reduces wear caused by plasma-cut metal sheets.

Flexible forming

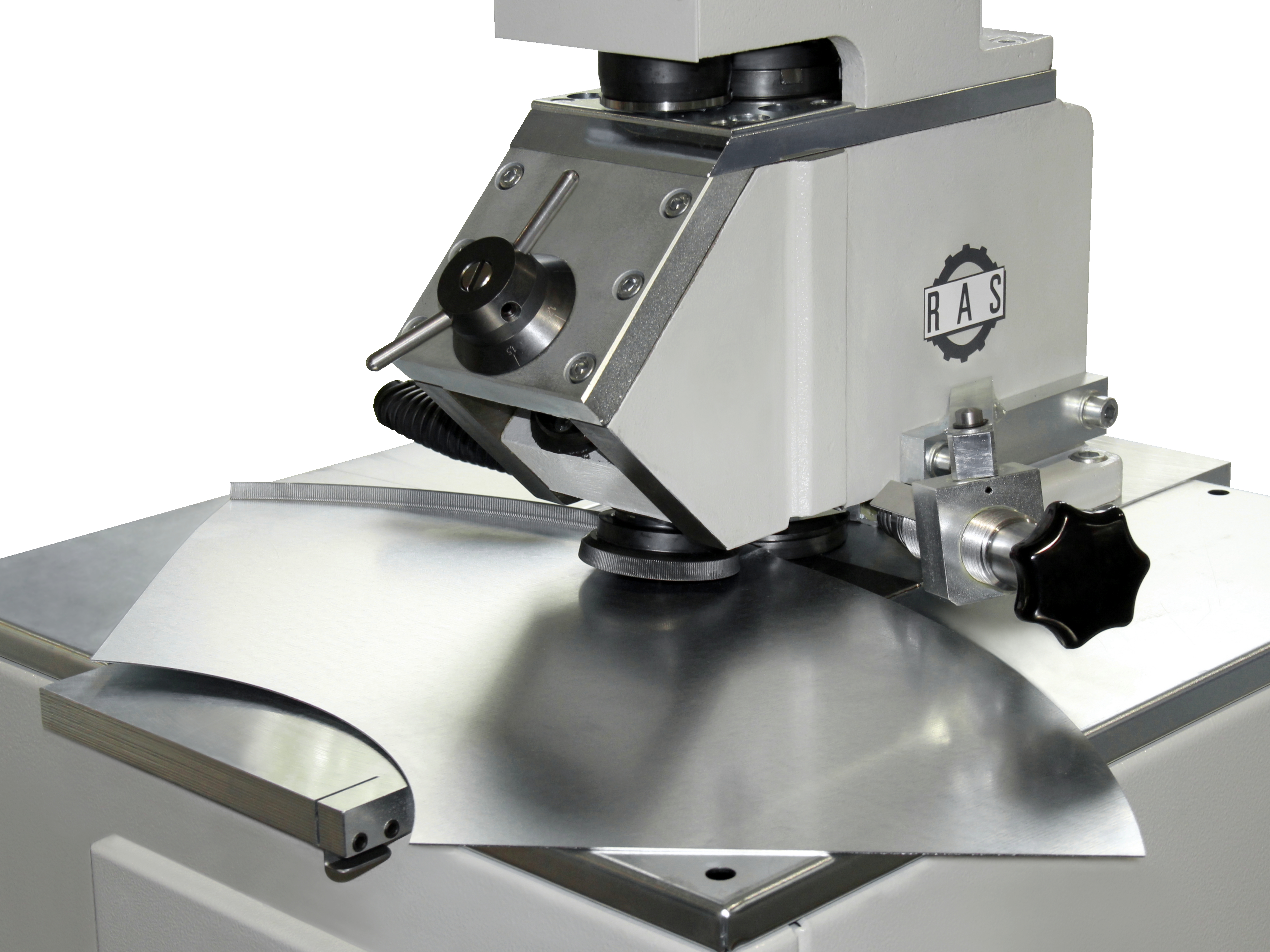

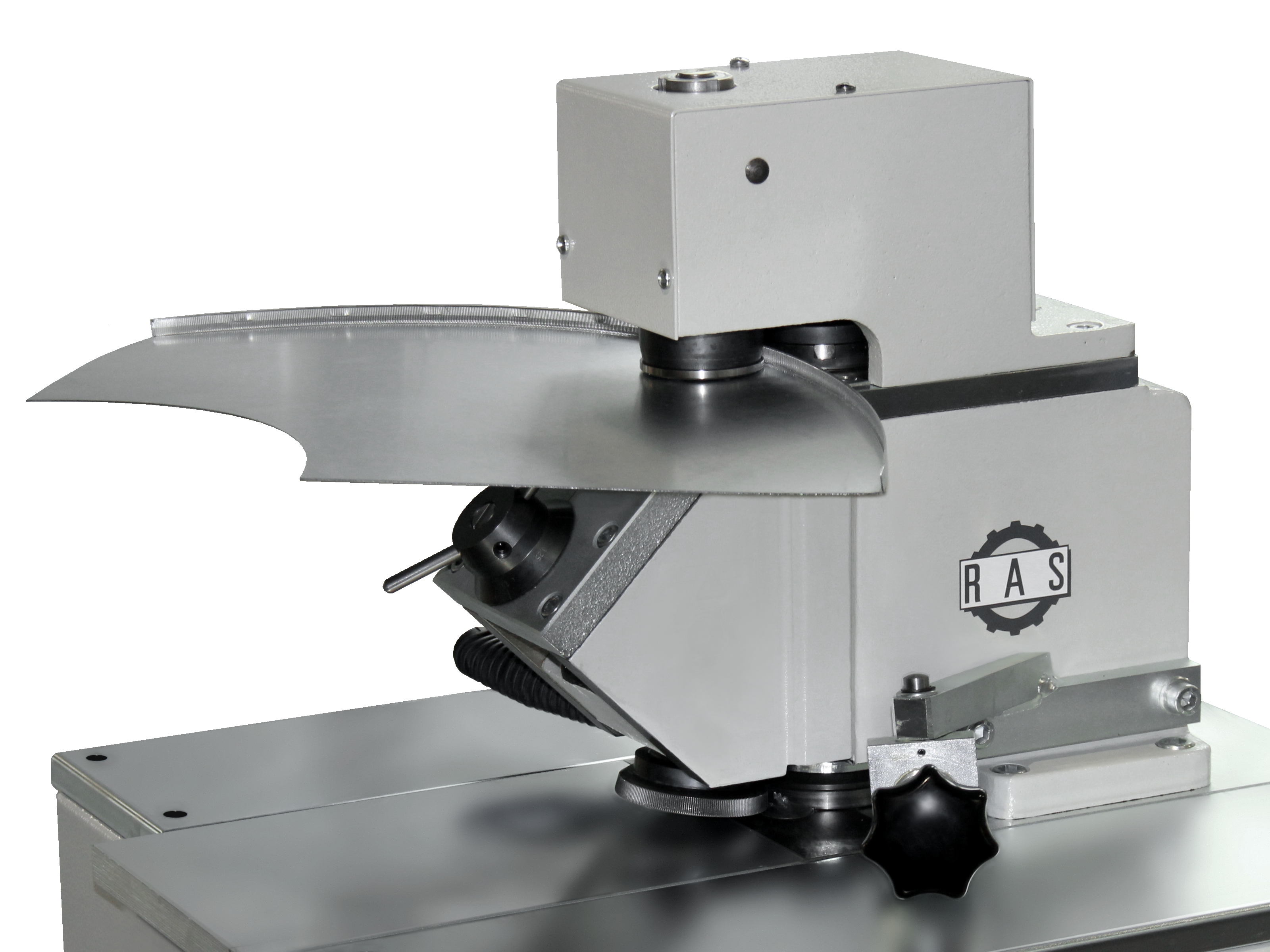

The forming rolls of the RAS flanging machine can create different flange heights - matching the required joints. For Pittsburgh joints flange heights of 8 and 10 mm should be selected. Snap-lock joints require flange heigths of 10 and 11.5 mm. The automatic sheet guide simplifies the workflow so that even less experienced operators achieve constant forming results.