Gerüstet für die Zukunft

Die Blechnerei Johannes Schwär aus dem Schwarzwald ist ein dynamisch wachsendes Handwerksunternehmen. Das Wachstum kommt nicht von ungefähr. Vielmehr denkt Johannes Schwär immer schon einen Schritt voraus und will mit seinen Entscheidungen gerüstet sein für aktuelle, aber auch zukünftige Aufgabenstellungen. Die Investition in ein RAS XL-Center mit UpDown-Biegetechnologie zeigt das fortschrittliche Denken des Unternehmens. [mehr] [Video]

Investment in the future

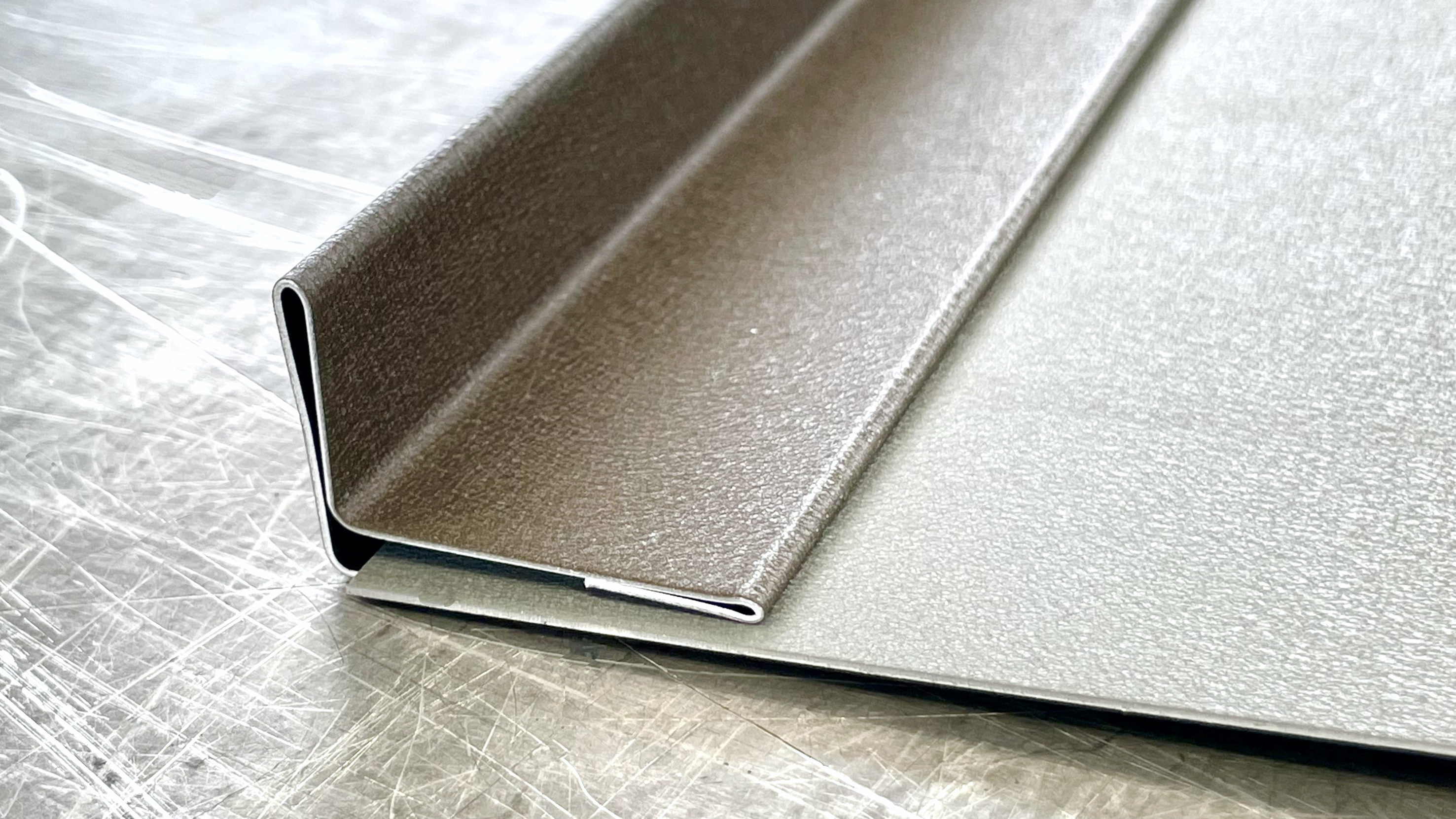

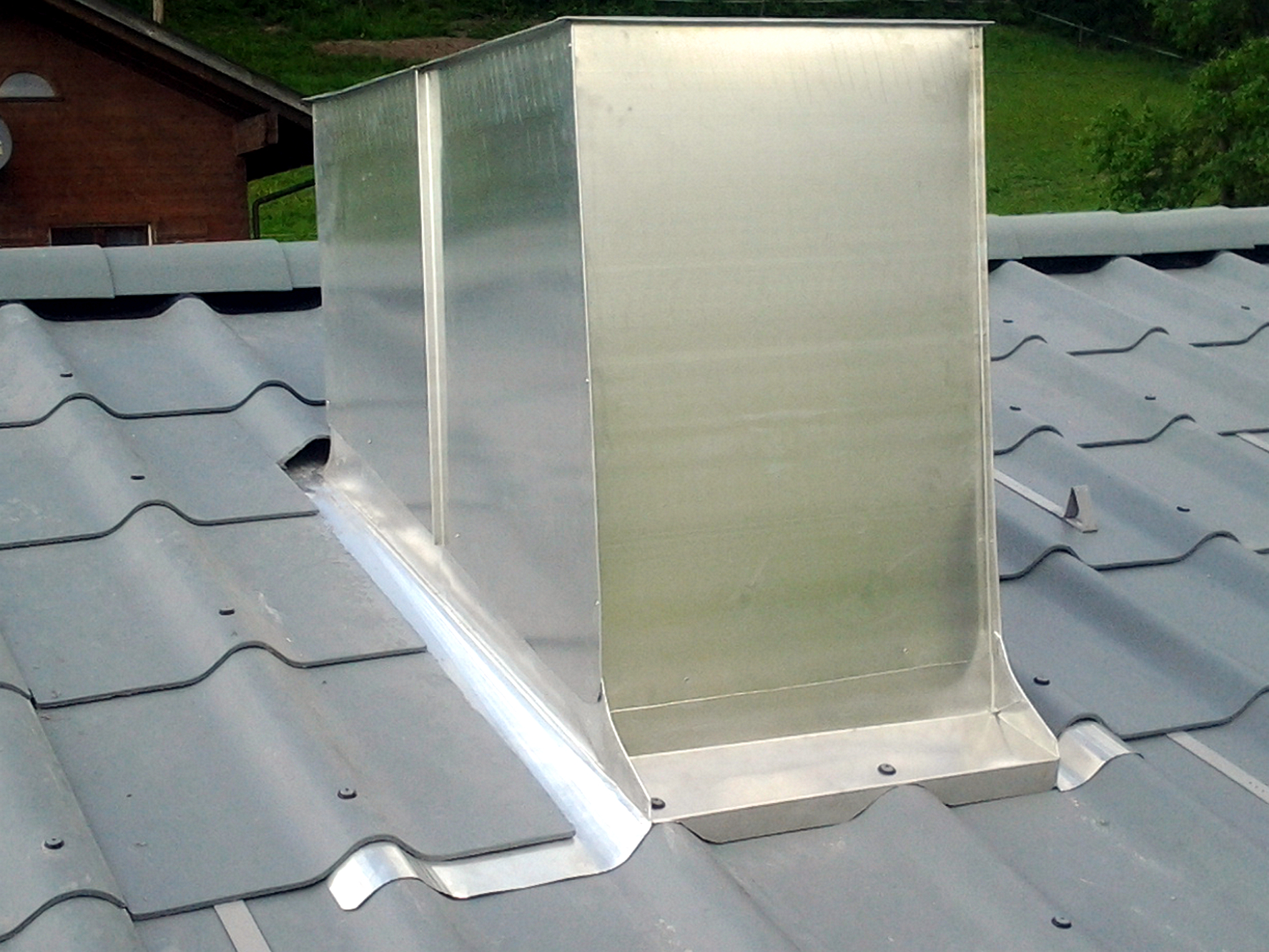

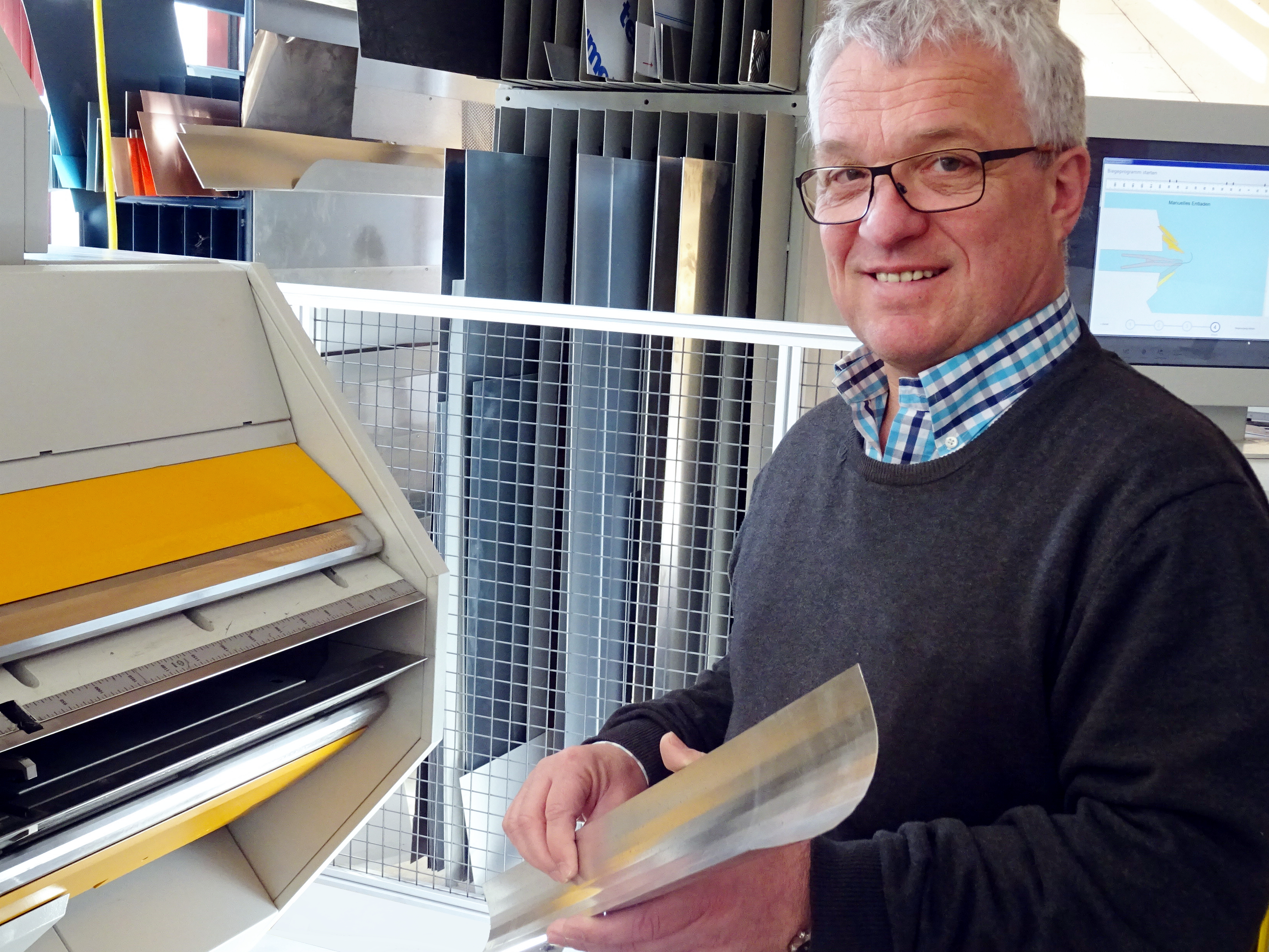

After the decision to modernize the machinery had been made, the only remaining question for Johannes and Thomas Binder was whether to re-invest in a traditional metal folder with only upward bending. In the end, the two roofing professionals decided in favor of a state-of-the-art RAS XL center with UpDown bending technology. "The XL-Center more than compensates the higher investment costs with its additional benefits," summarize the two entrepreneurs. [more] [Video]

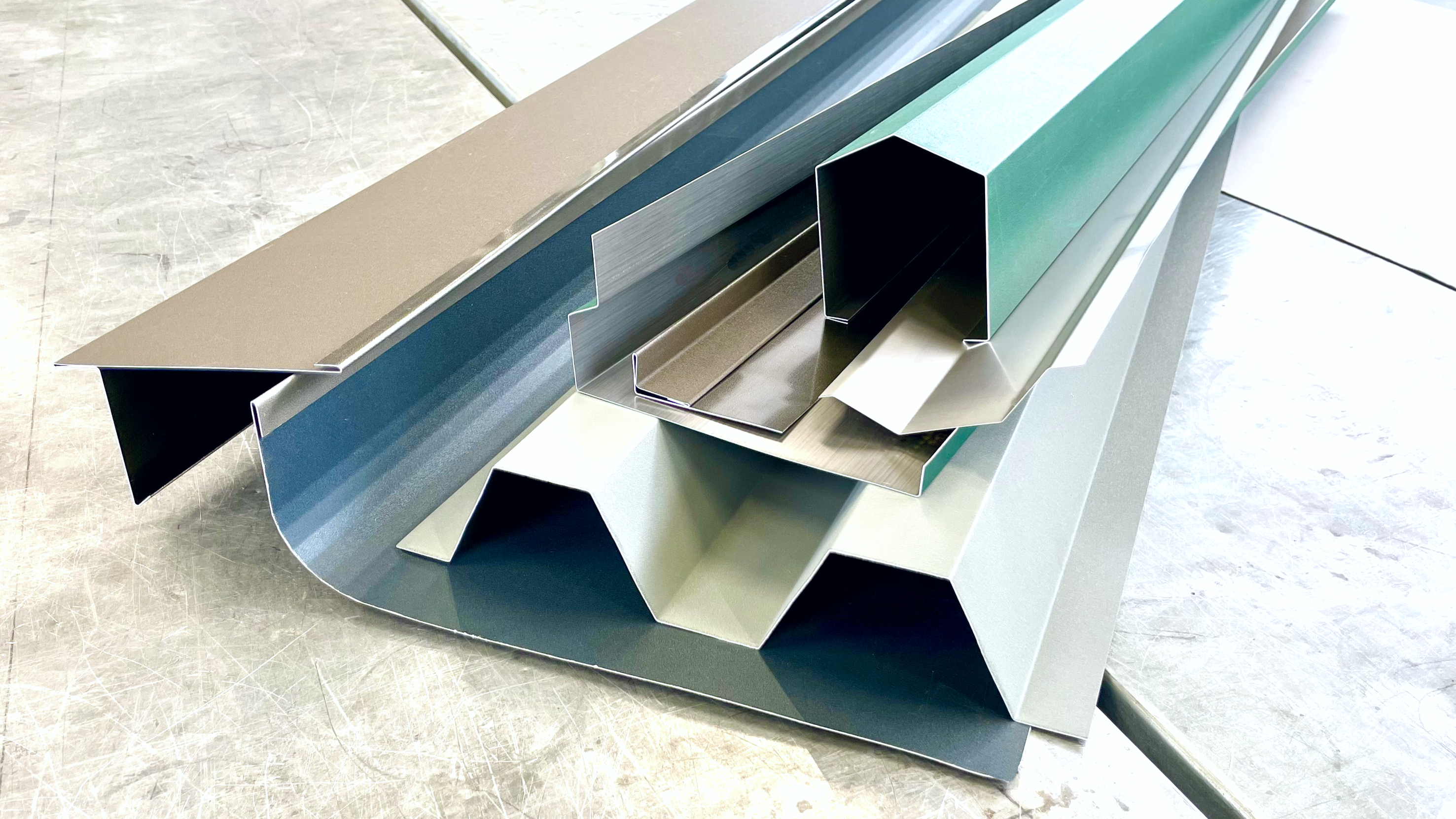

Comparing two folding technologies

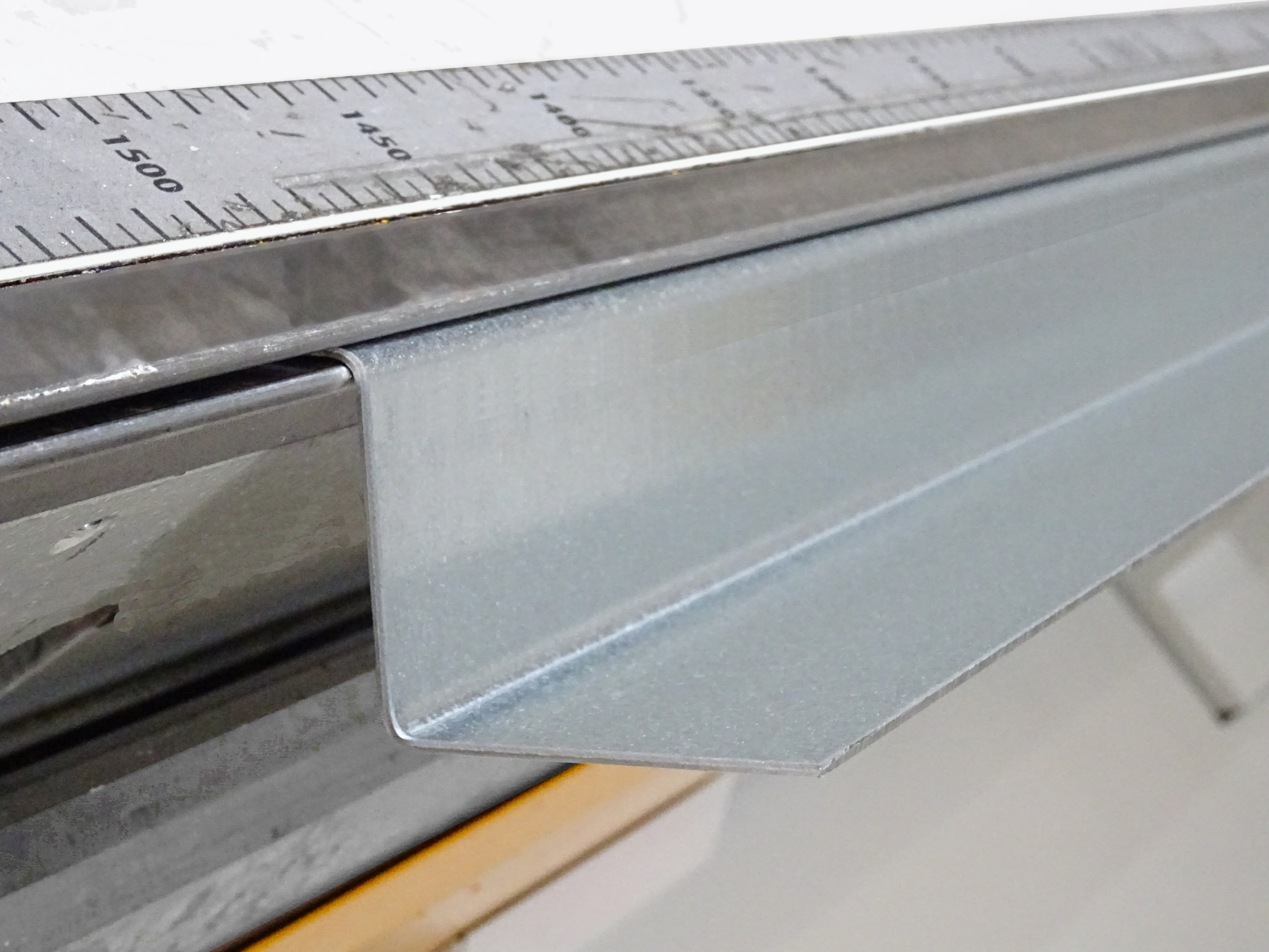

For two generations, Begoin GmbH has been a synonym for solid and reliable roofing. Through the precision processing of high-quality materials, the Bad Hersfeld based company has earned a high reputation in the regional market. Three RAS machines assist in meeting the company's performance promises in terms of quality and on-time delivery. Cuttings is done on a RAS SMARTcut swing beam shear. For bending, a RAS TURBObend plus as well as the UpDown folder RAS XL-Center are used.

[more] [Video]

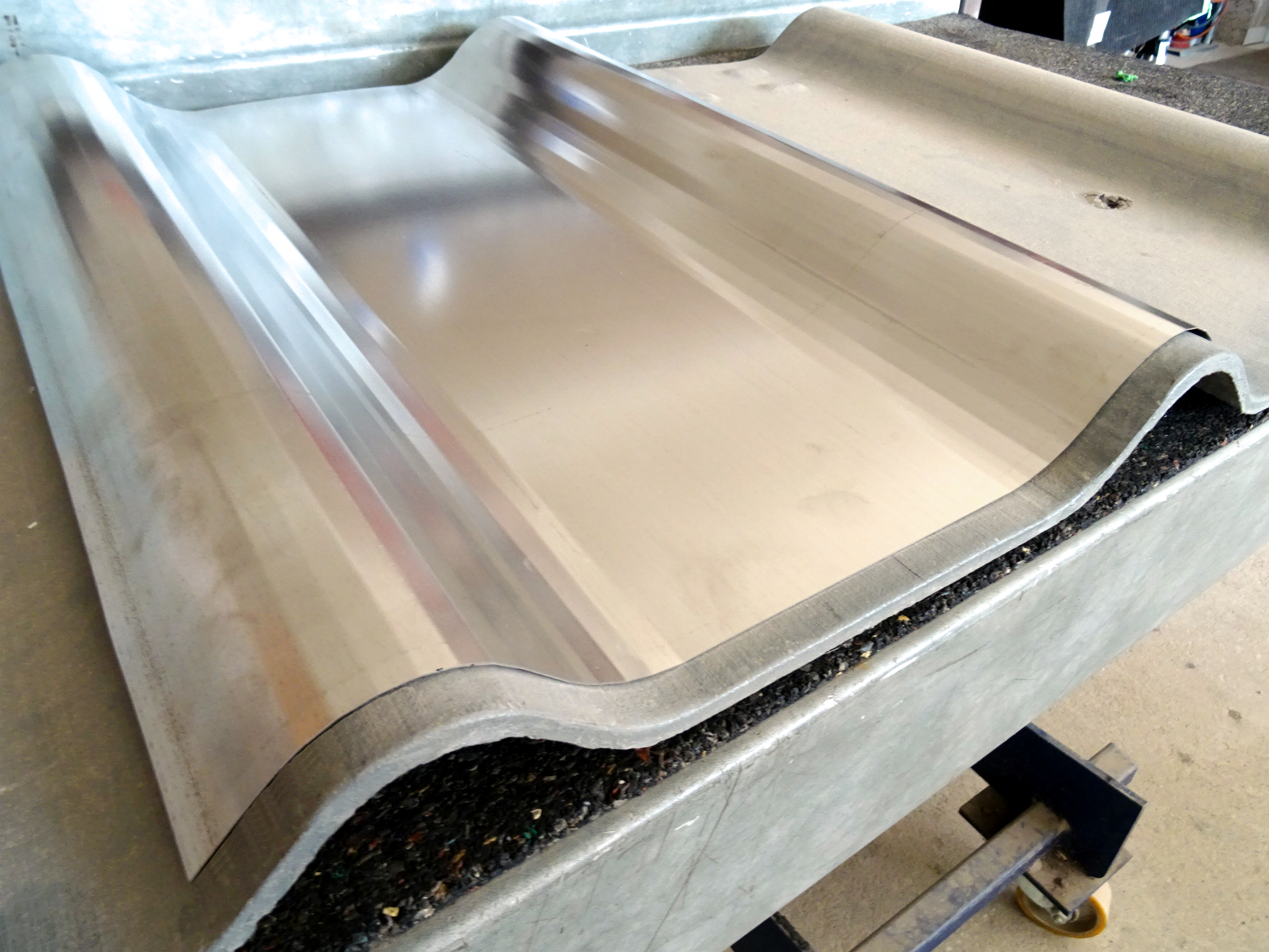

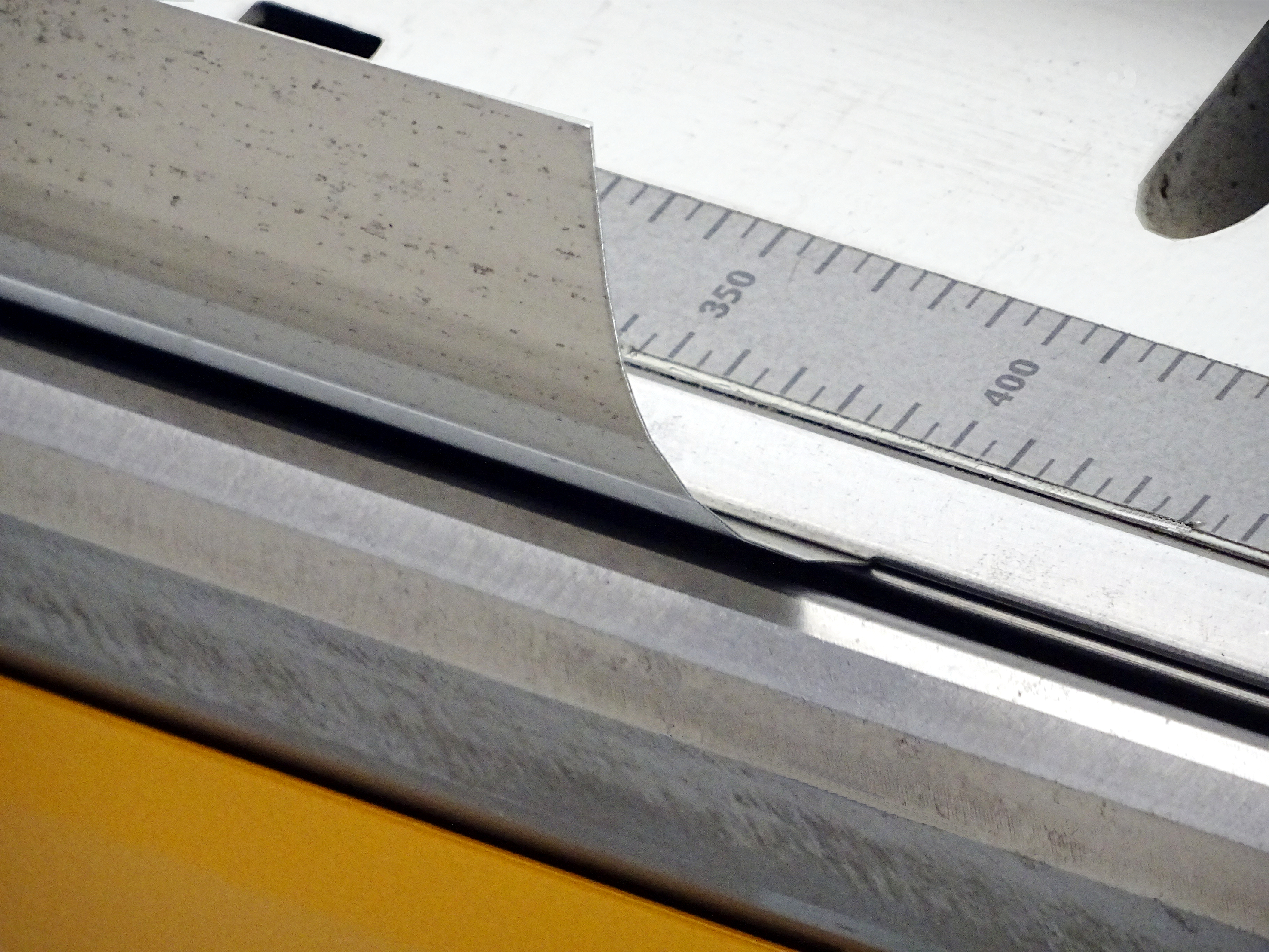

XL-Center: Bending a roof ridge

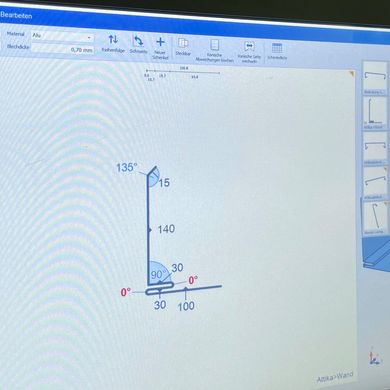

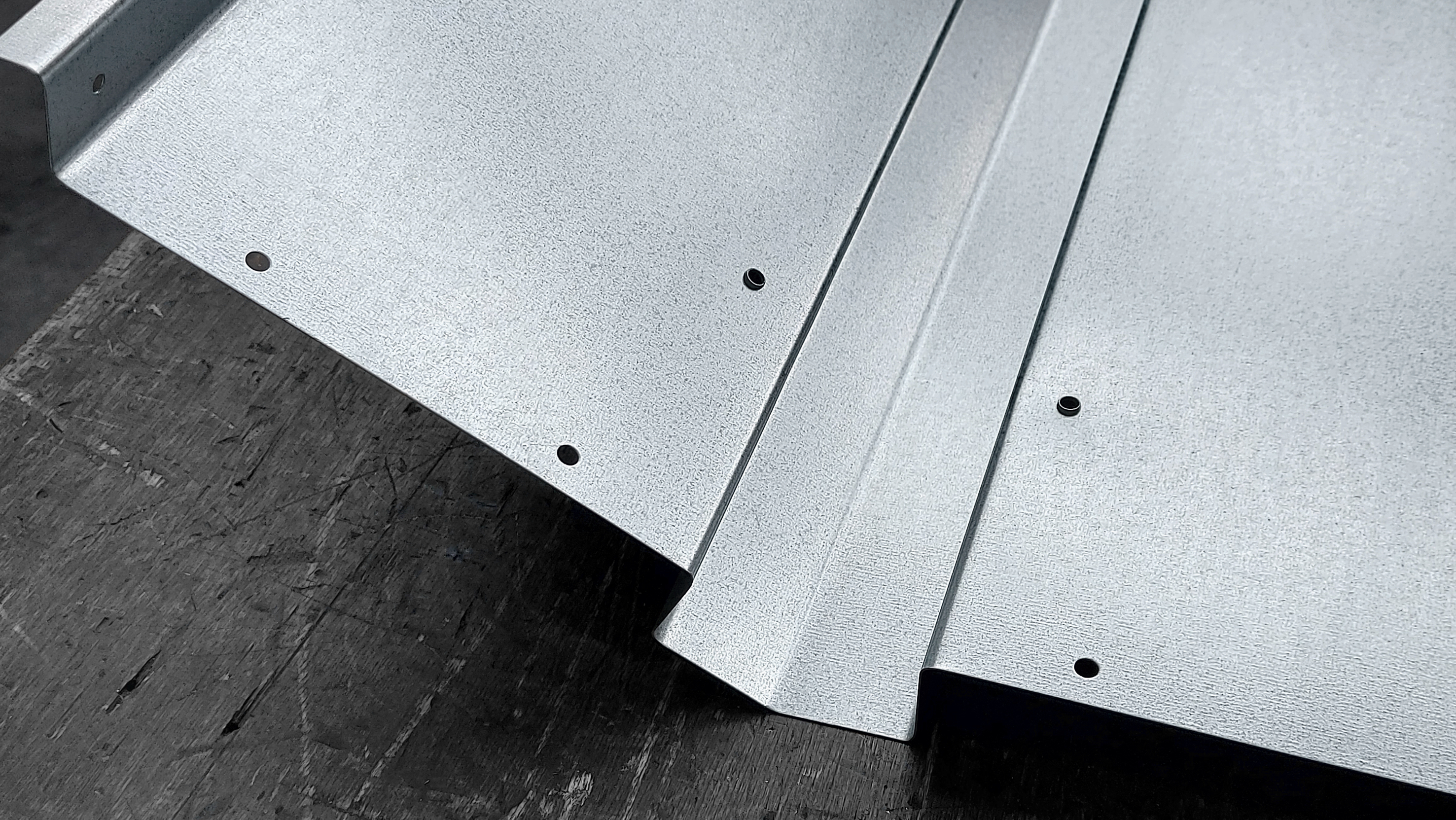

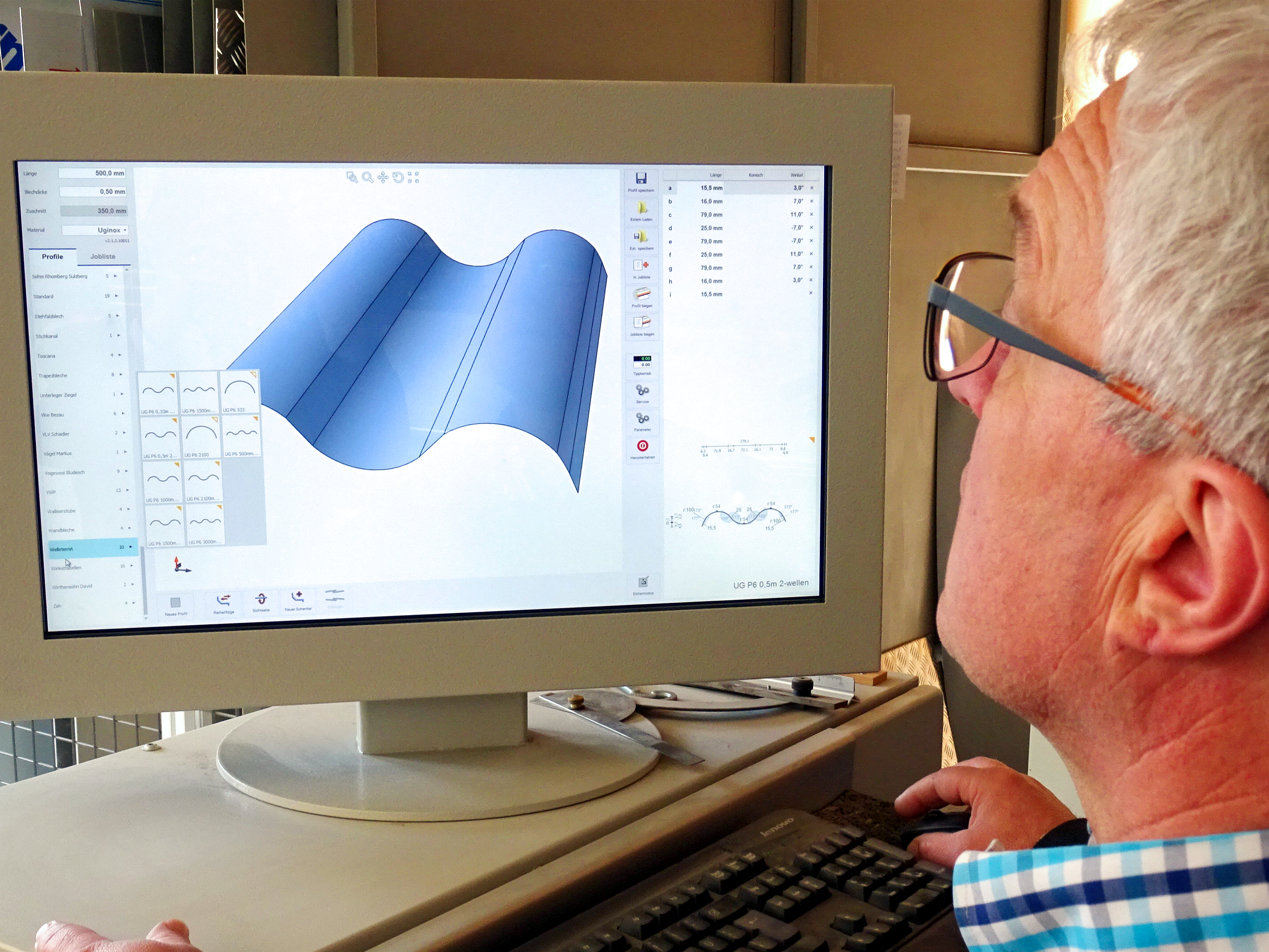

When automatically bending a roof ridge profile, the RAS XL-Center UpDown bending center shows all its skills. There are already embosses in the sheet for later fastenings. Therefore, the upper beam must gently clamp the sheet so that the embosses are not damaged during bending. The Bendex software automatically programs the bending sequence based on the drawn profile. [Video]

Digitizing the Construction Site!

Stefan Bern is a roofing and façade specialist for demanding residential buildings. With a team of 30 employees, the company produces all metal parts in their workshop. Their own skilled workers assemble the profiles on large private properties in the area. With the RAS XL-Center, the company has significantly increased its efficiency and bending speed. [more]

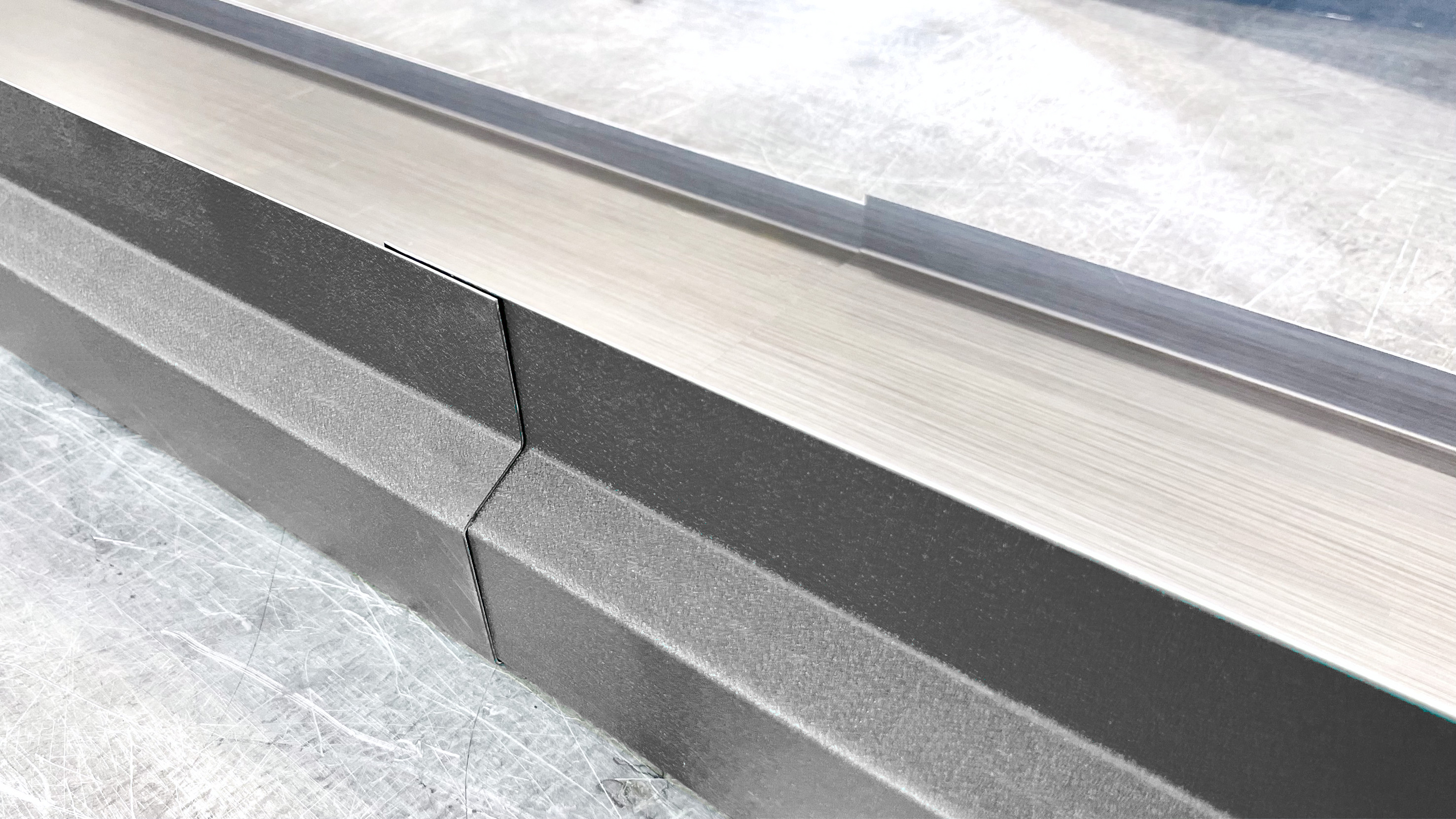

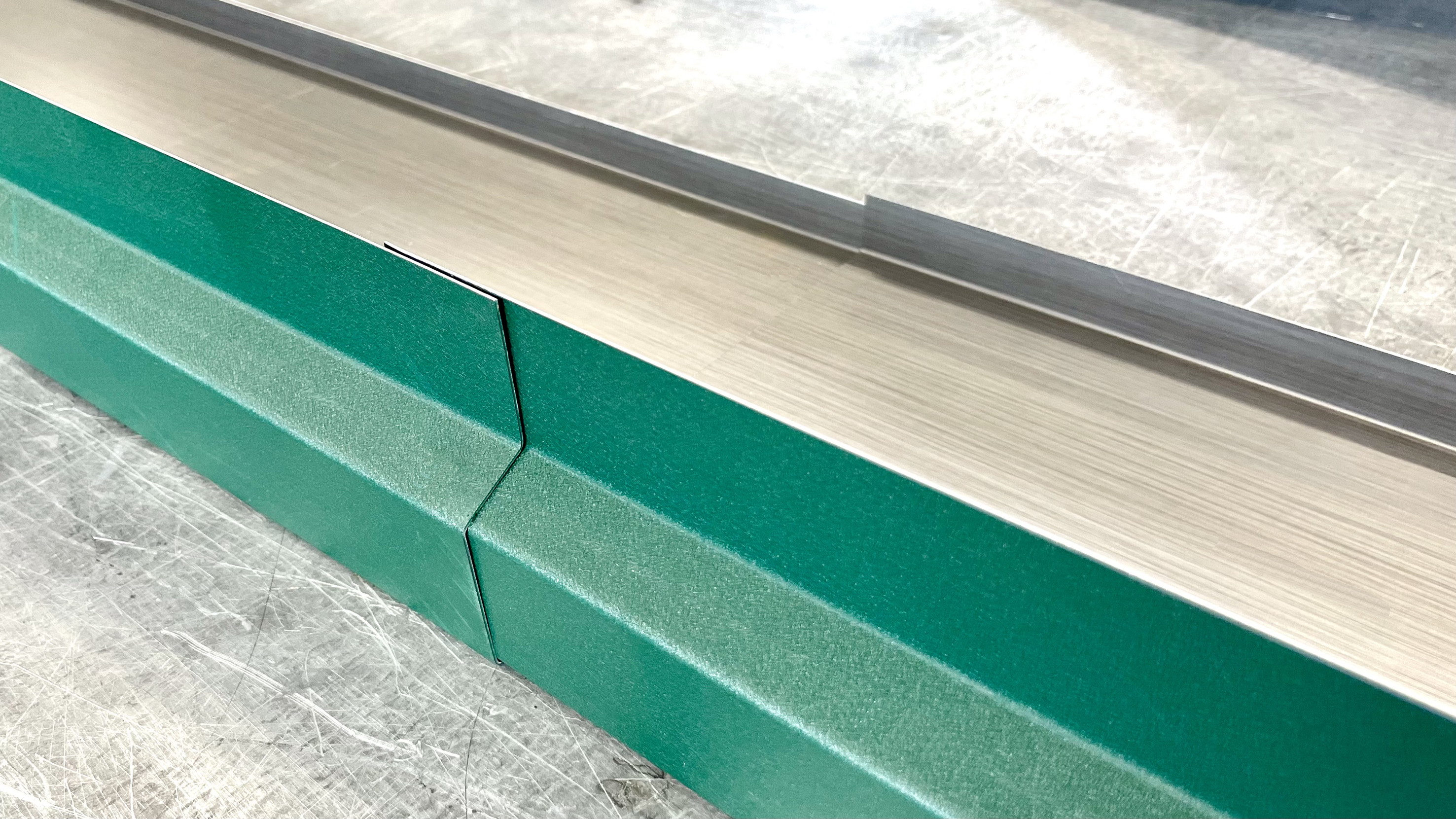

Metal fabrication with up-down bending

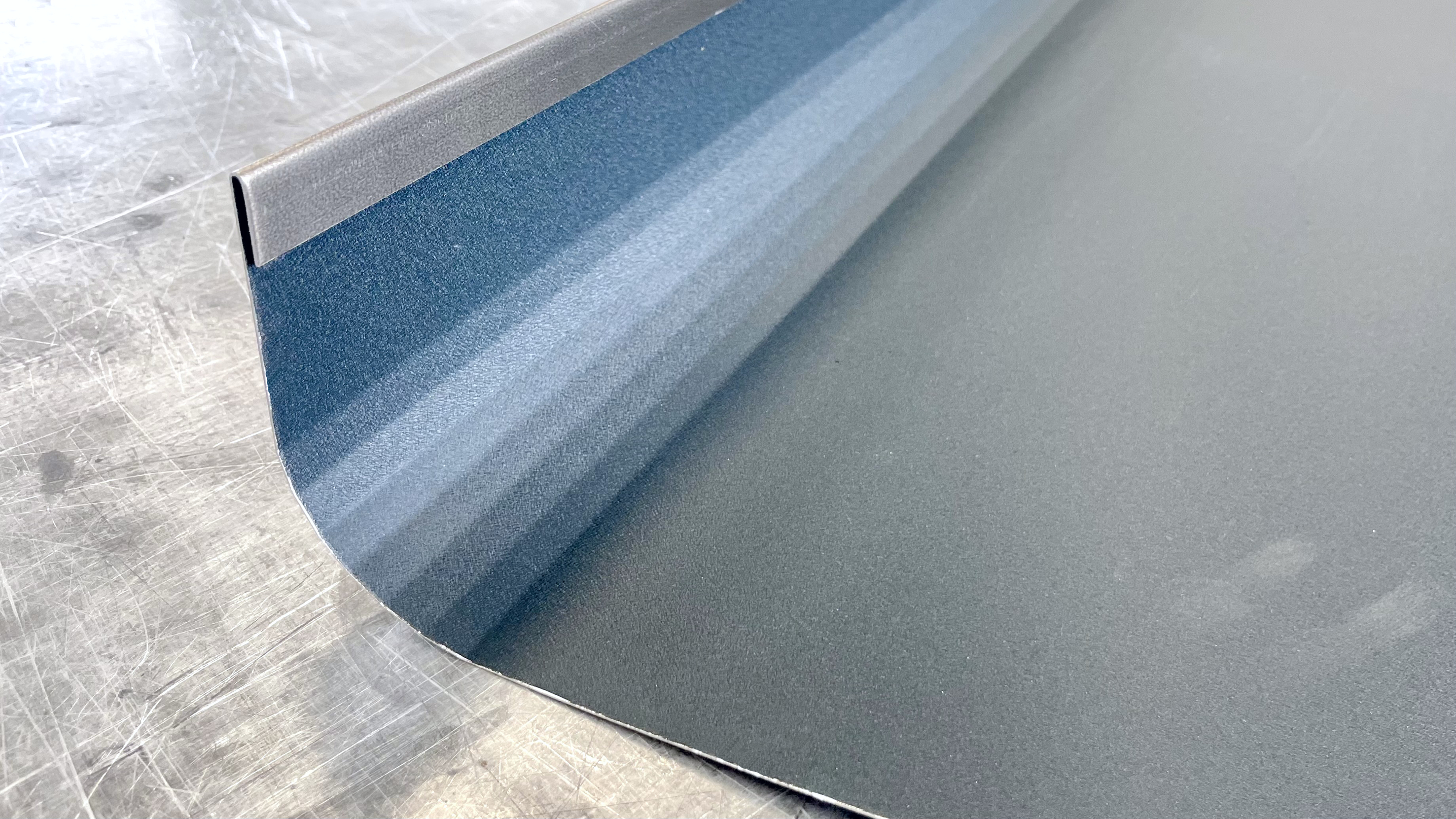

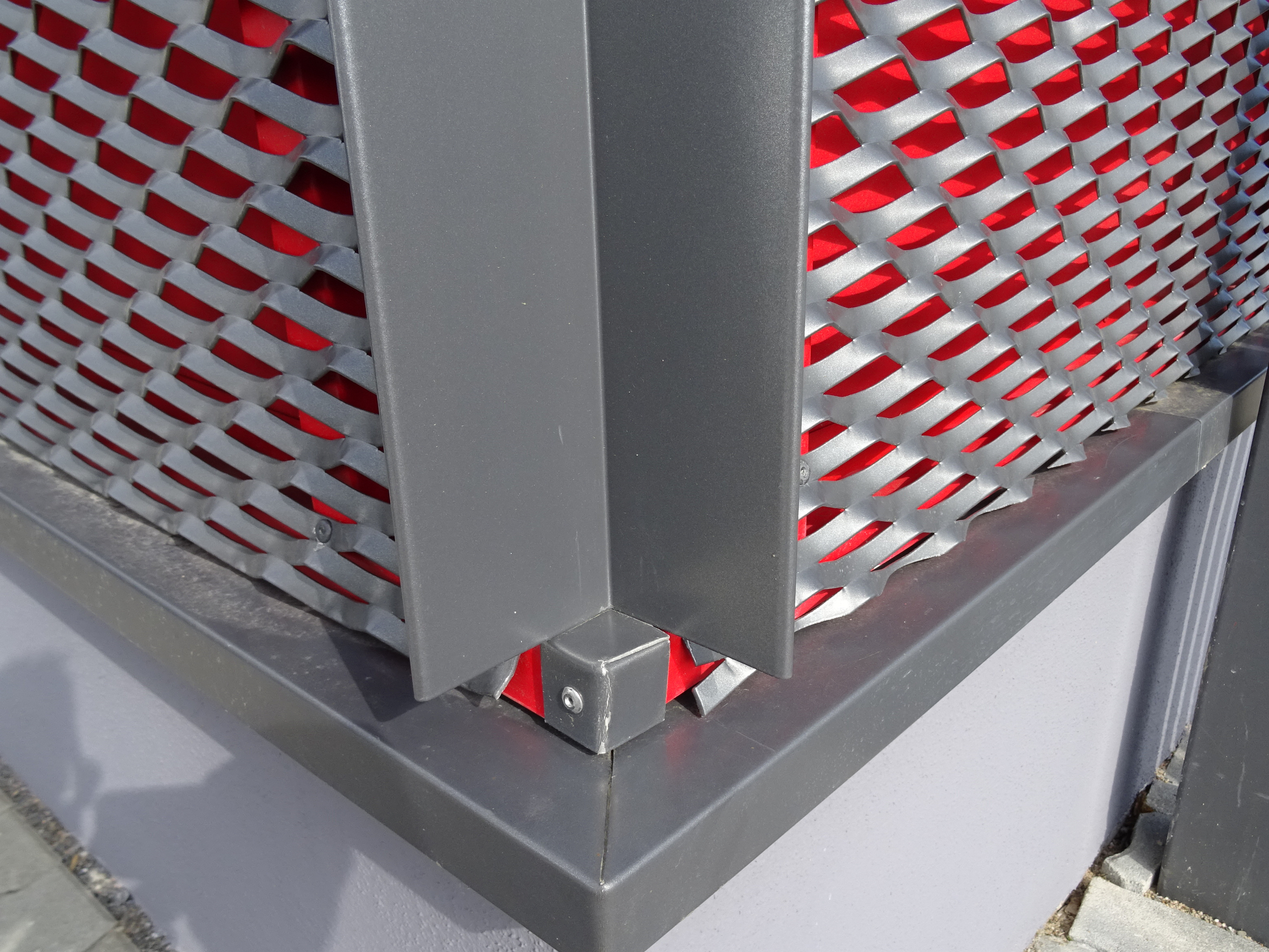

Roofer Leib reports on their Website: "As a result of the growing demands of modern architecture, ever more complex metal profiles are required. We can produce them now efficiently and precisely by the purchase of a new XL bending center from RAS. The required profiles can be designed directly in the office and sent to the machine. The machine geometry allows the metal to be folded in two directions, which saves expensive material handling time."

From YouTube to a finished part

When Carl Schmidt began looking for a new metal folding machine to produce profiles for commercial construction, he took an unusual route. Instead of visiting trade shows or different manufacturers, he started watching YouTube clips of the different manufacturers. He was so impressed by the RAS XL-Center that he decided to place an order without ever seeing the machine live. What might seem to some like a rushed action was, in reality, carefully thought through. [more]

It’s simply fun!

Manfred Baldauf and his wife first saw the RAS XL-Center at the DACH+HOLZ (Roof+Wood) show and immediately fell in love with the machine. The roofing and tinsmith company from Doren (Austria) works on both residential housing construction and with commercial developers and builders. The capability to form unique and unusual facades has most impressed Manfred Baldauf and the RAS XL-Center can bend exactly these profiles with whimsical shapes, radii and hems. [more]