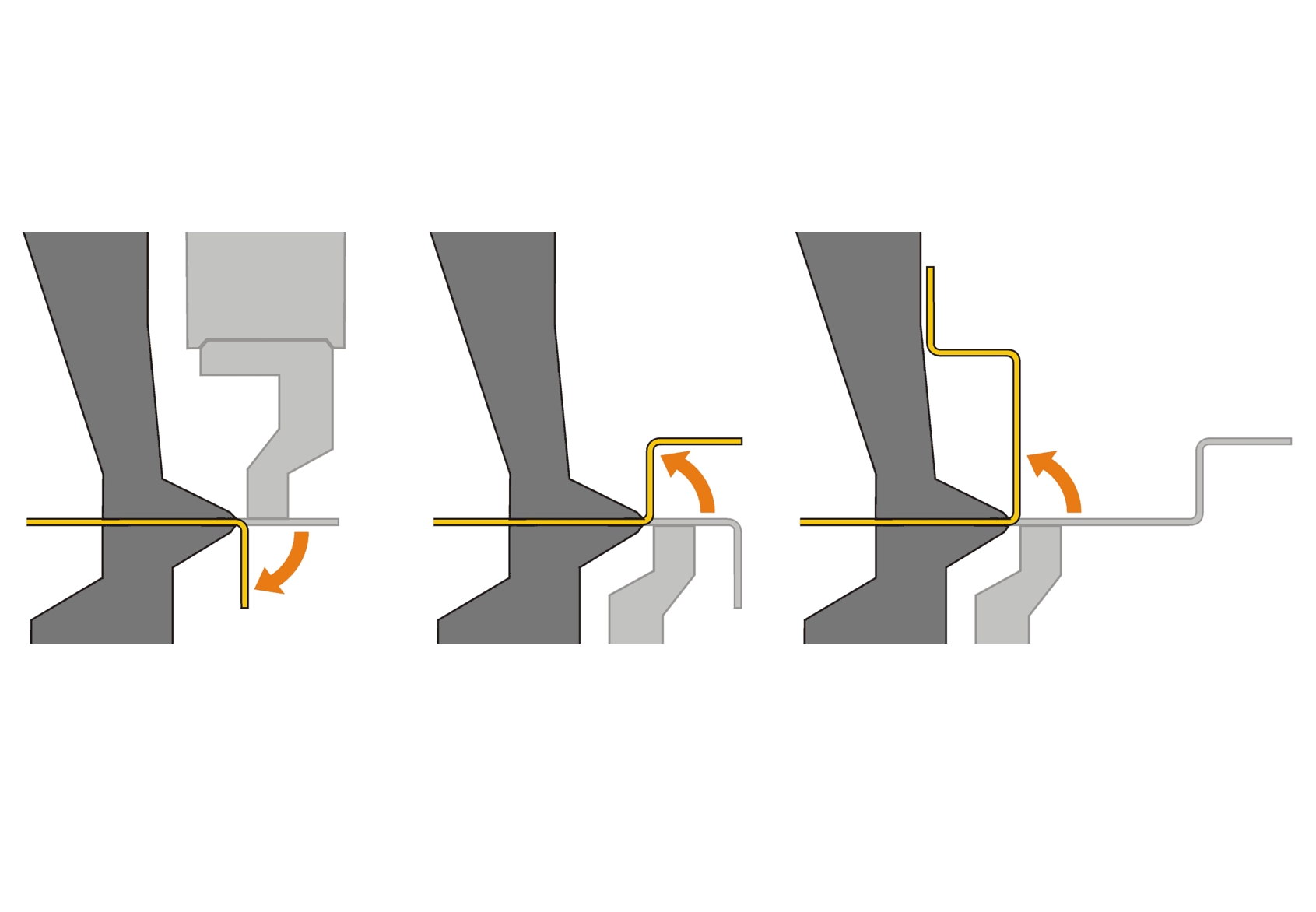

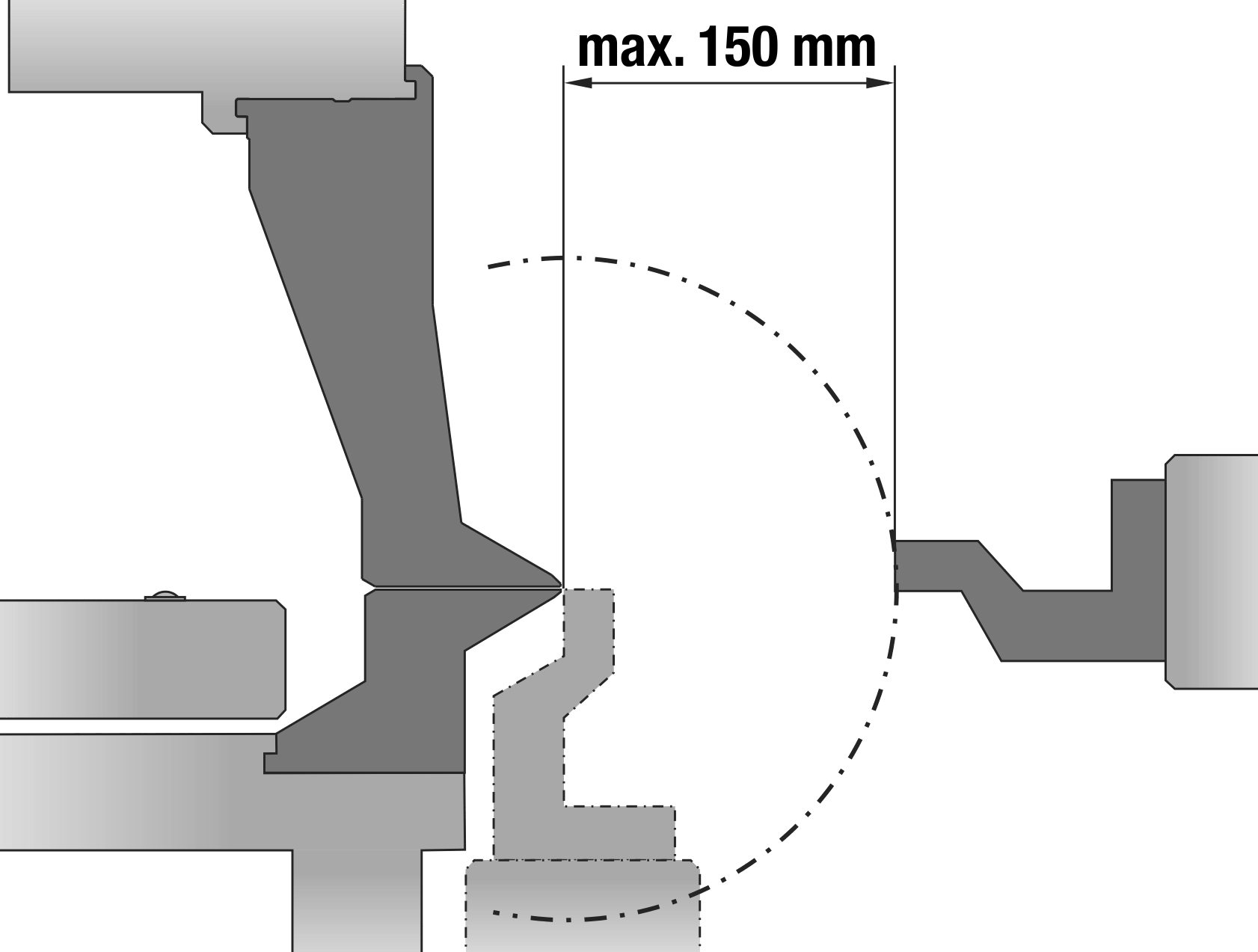

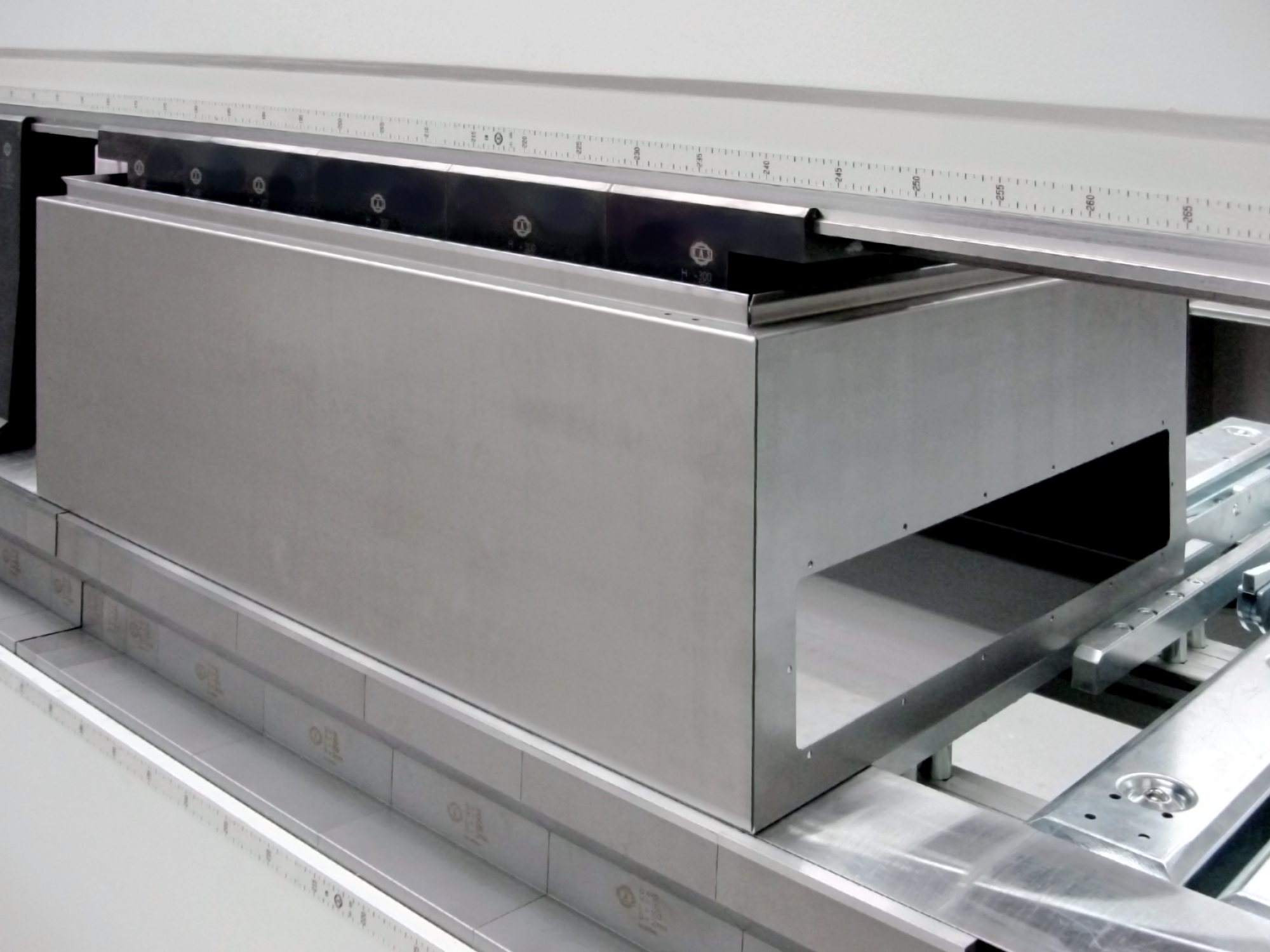

Telescopic gauging system

The unique telescopic gauging system automatically adjusts to the actual bending situation.

Telescope pushed together:

- Bending of small / narrow parts

- Operation close to the bend line

- Ergonomic working position

Telescope pulled out:

- Bending of large parts

- Part weight fully supported

- Power saving operation

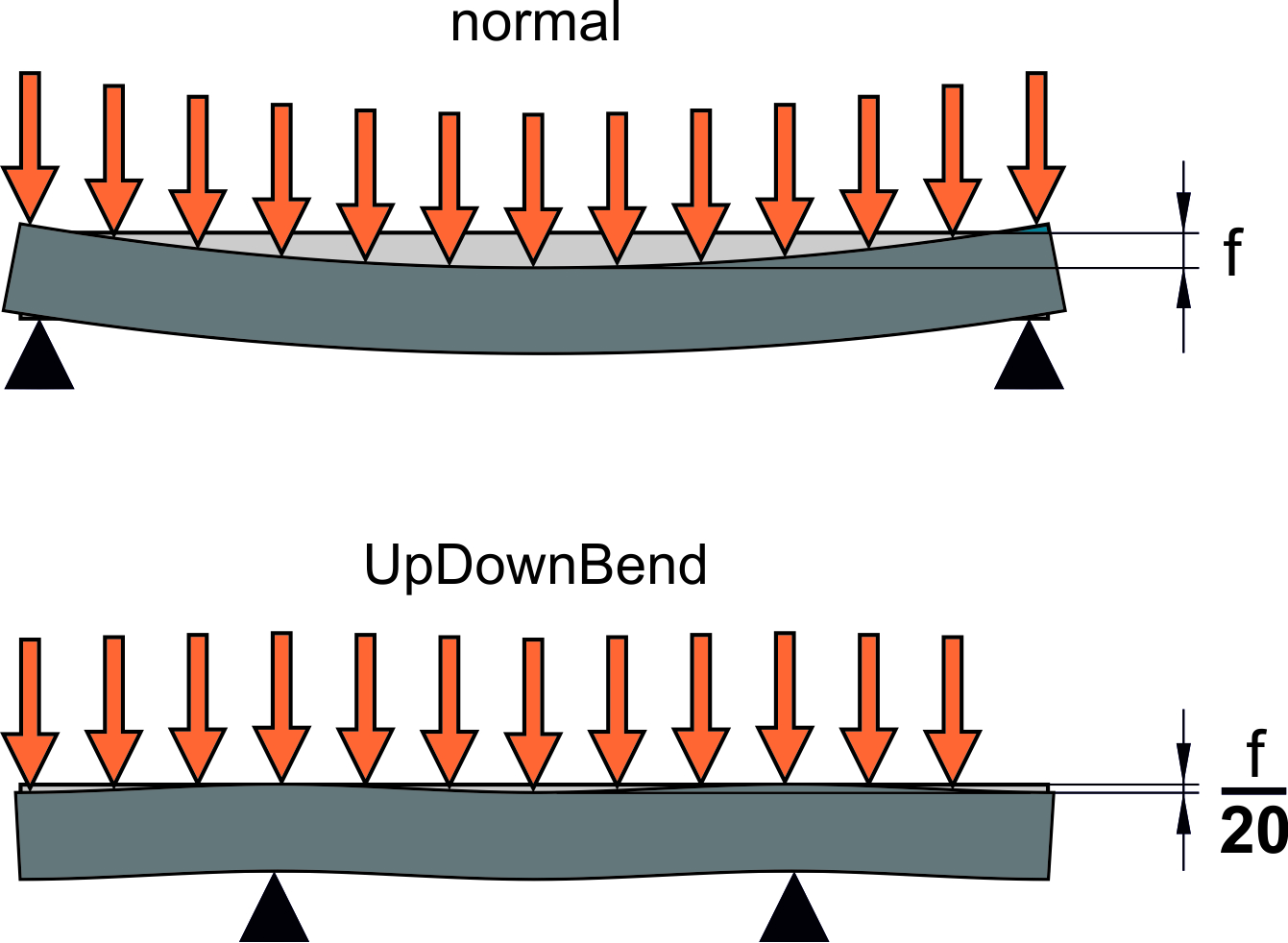

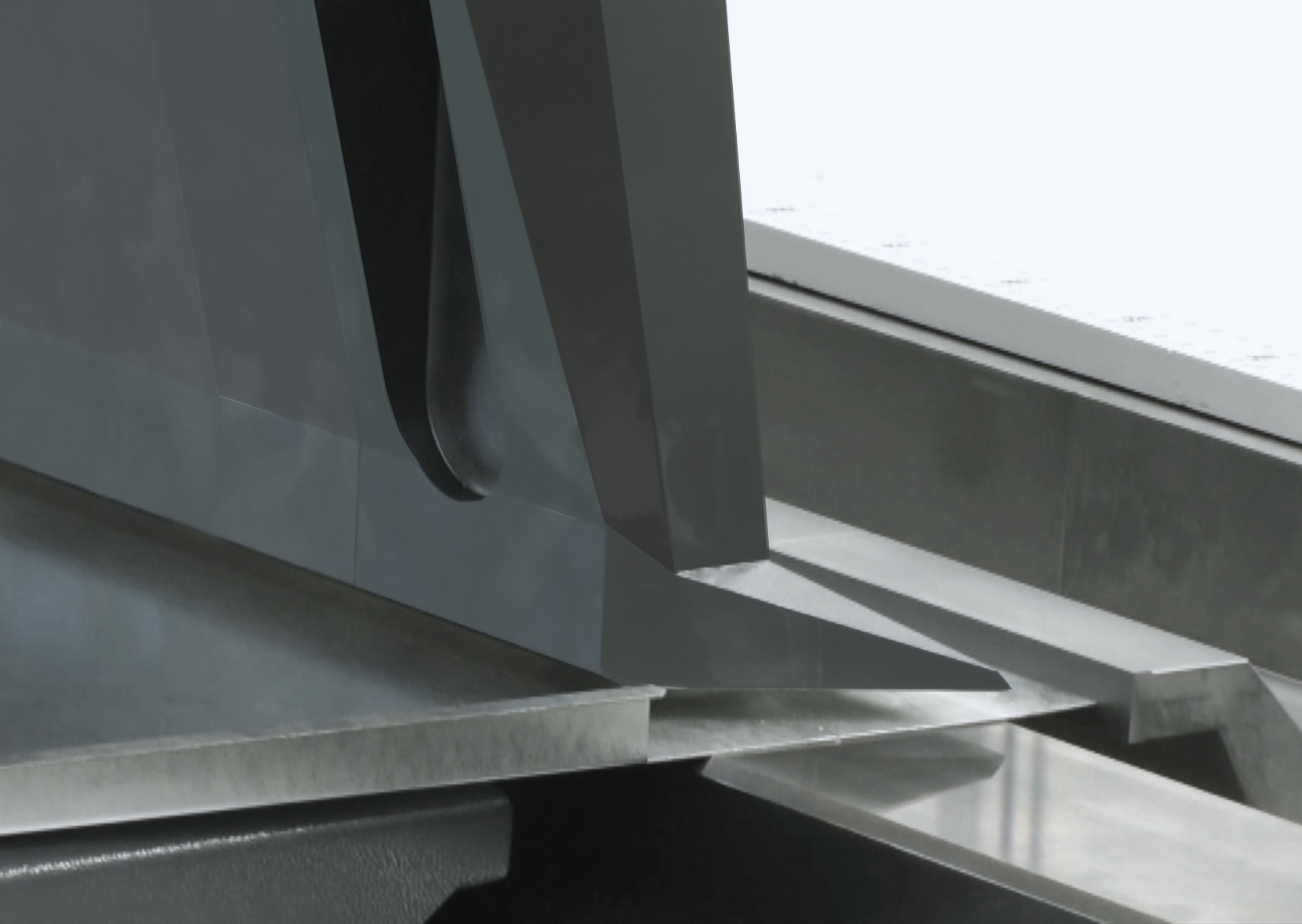

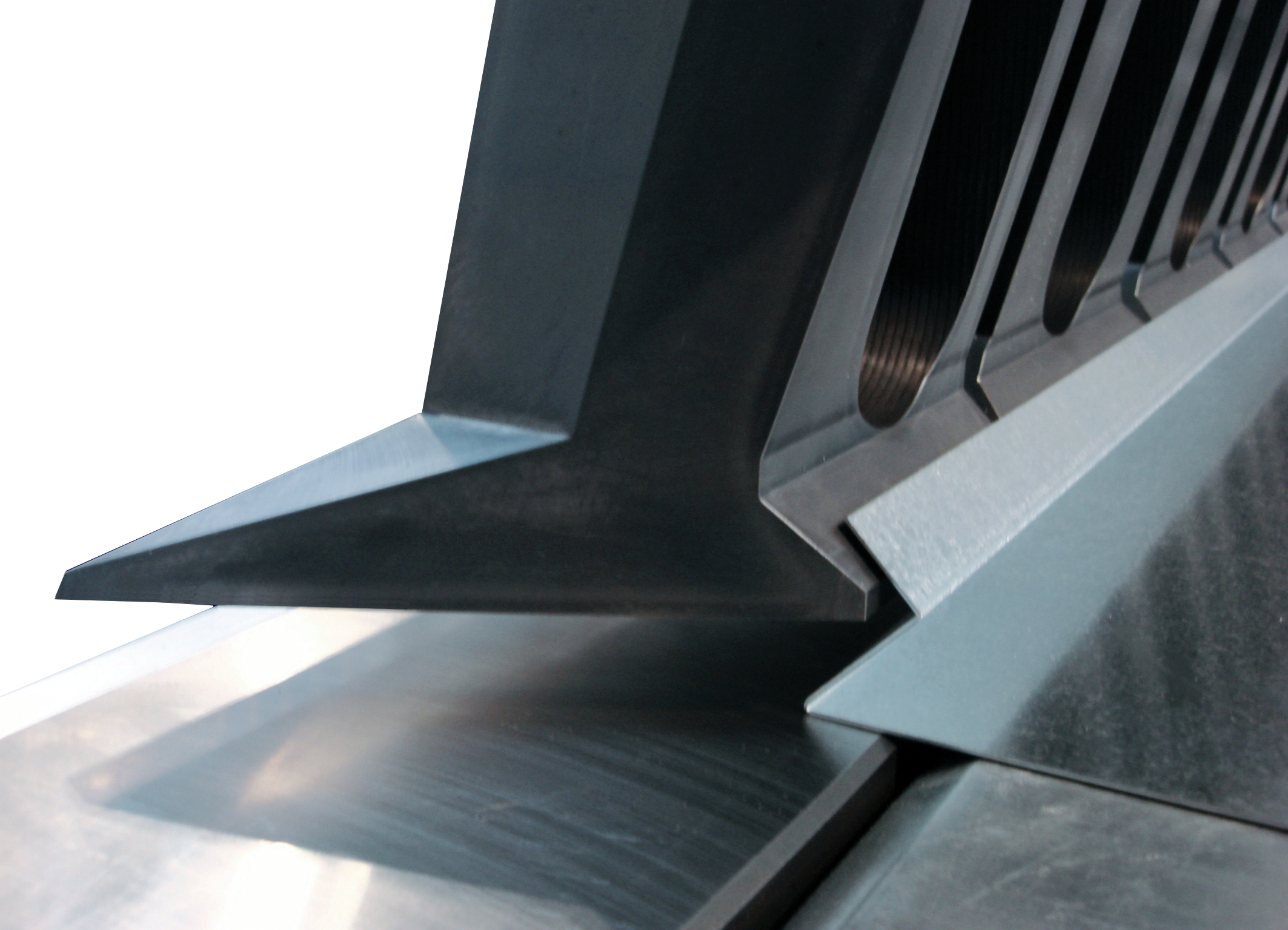

Straight bends

The UpDownBend uses the RAS patented beam-in-beam design. With this design the folding beam almost does not deflect when loaded by the bending force.

- Straight bend without a need for adjustments

- No crowning system needed

- Additional use: folding beam can be used as a stop

- Bending of inclined blanks

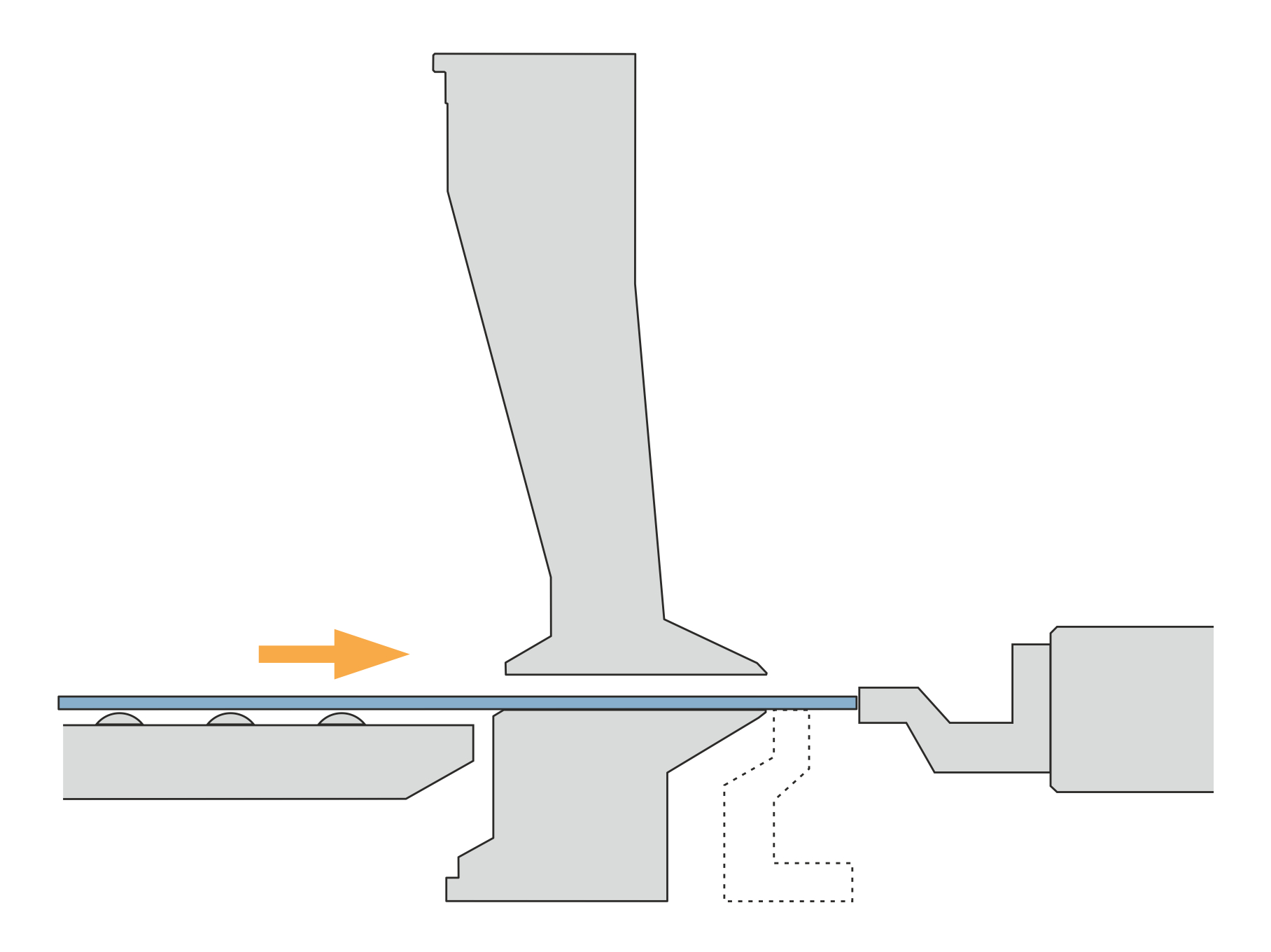

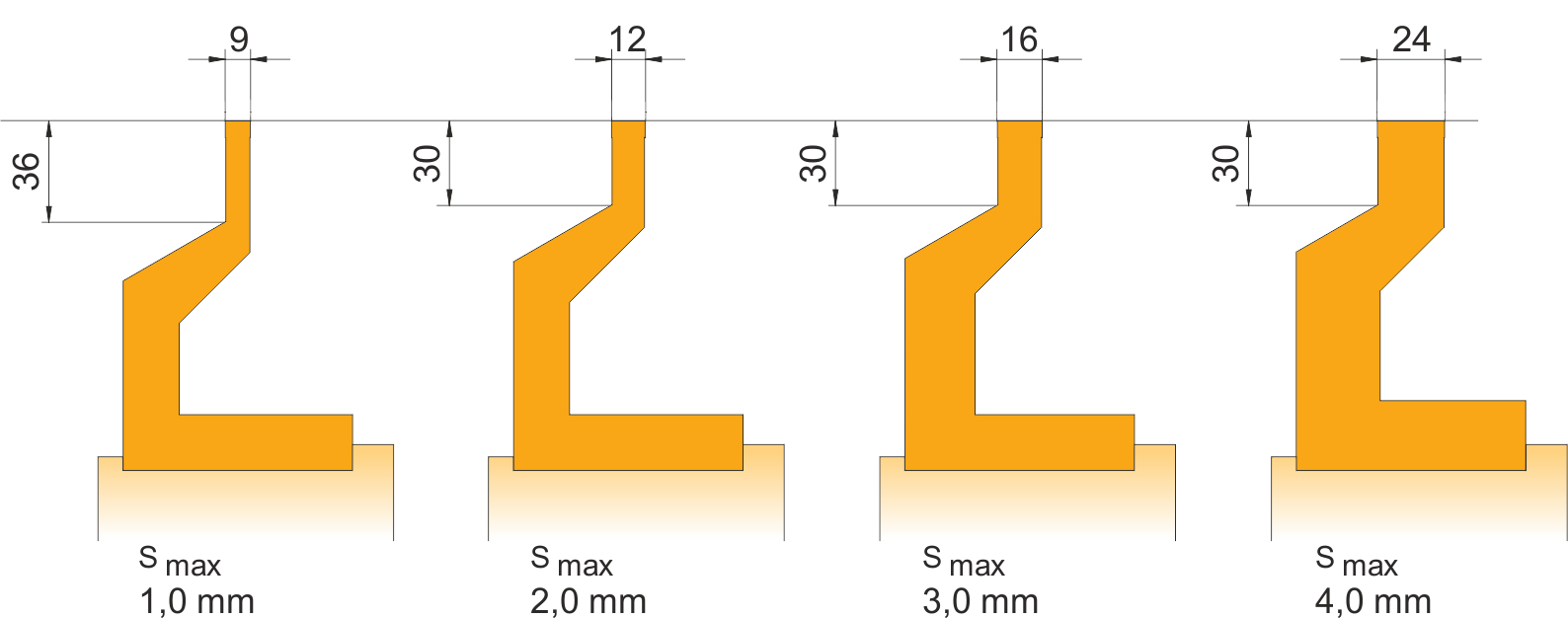

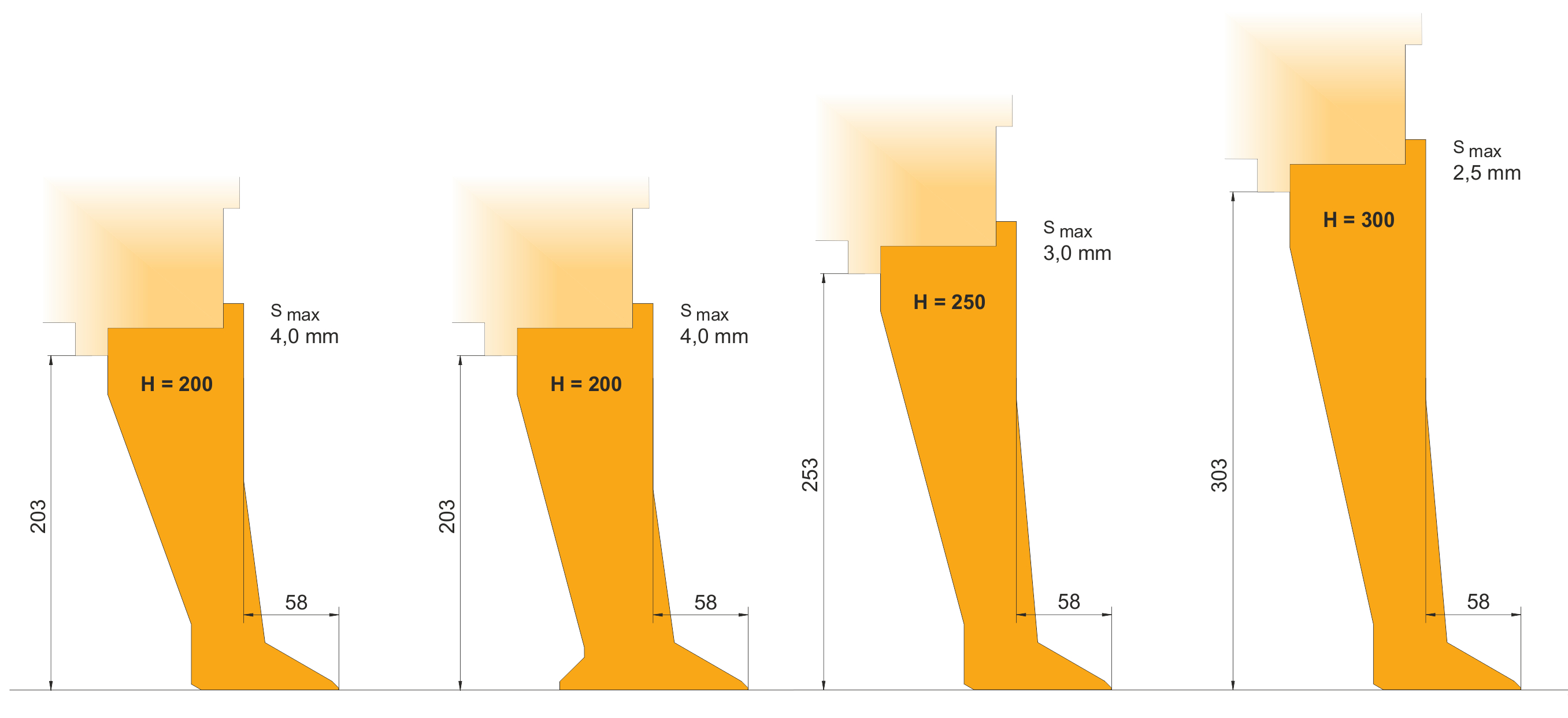

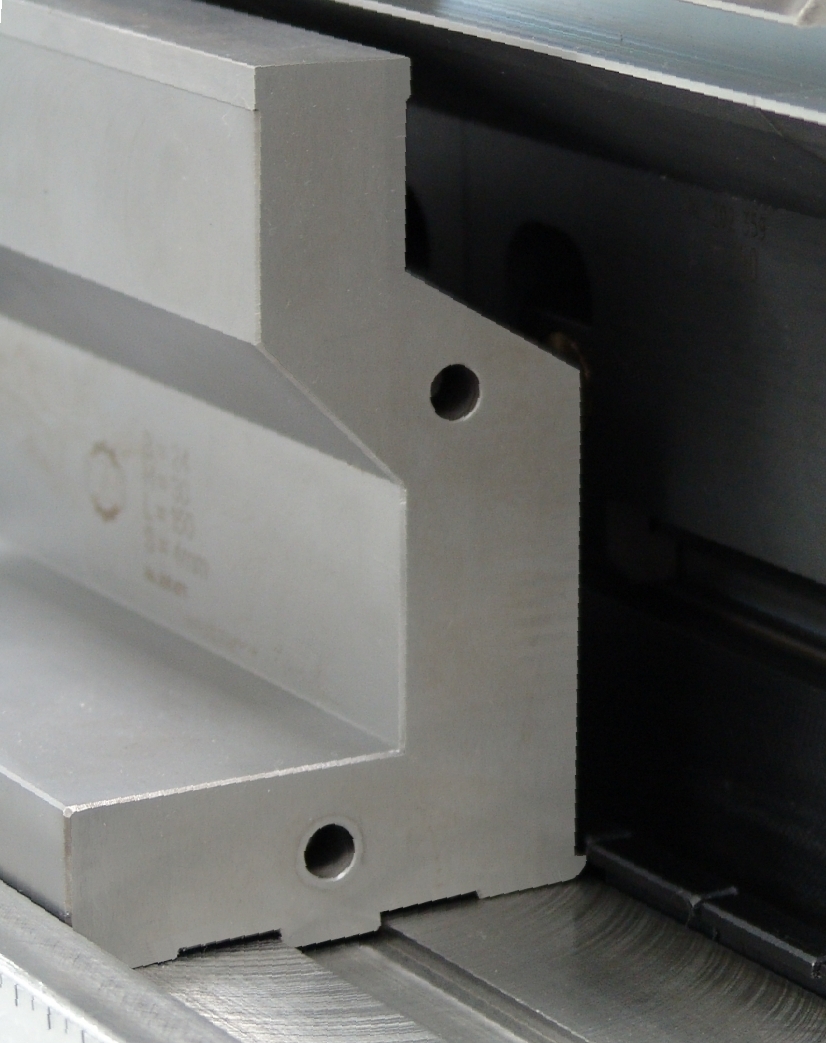

Variety of tools

Ideally, all parts can be bent with a single set of tools. Which tool suits best depends on the box height, the material thickness and the tool geometry requirement.

- Upper beam tools with/without heel

- Tool set with basic segments, adapters and corner tools

- Upper beam tools up to 300 mm in height

- Folding beam tools for different Z dimensions

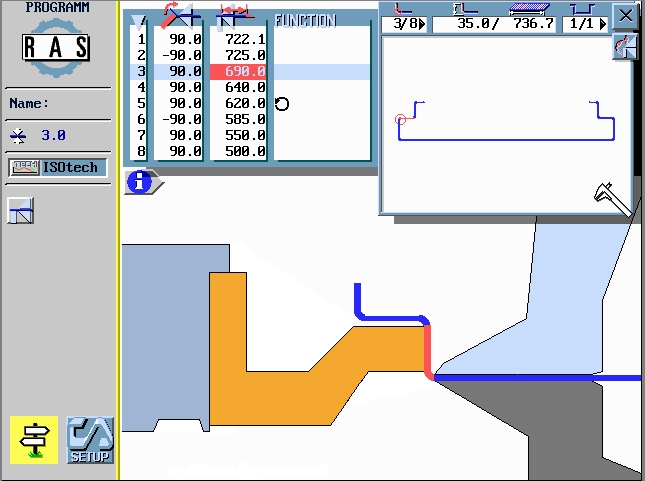

Universal machine control

The control can be supplied built in a moveable console or for optimized accessibility or for maximum access added to a swivel arm. The workshop-oriented programming software includes a large range of functions.

- Drawing the shape of the part with the finger

- Usually program will be automatically created

- Technological tables (angle correction / blank calculation)

- Software shows program, finished part and actual bending step

- Program library

- Operator instructions (text and icons)