Fireblock: Revolution in metal door production

In the heart of Ireland, Fireblock, a visionary manufacturer of fire and explosion resistant doors and windows, has achieved a remarkable breakthrough in metal fabrication. By implementing advanced technologies, the company has managed to increase productivity fivefold while establishing new quality standards. Read here how this is possible in detail

[more] [Video Mulibend Center][Video Profile Center]

Schneider-Electric: Efficiency increased by 410

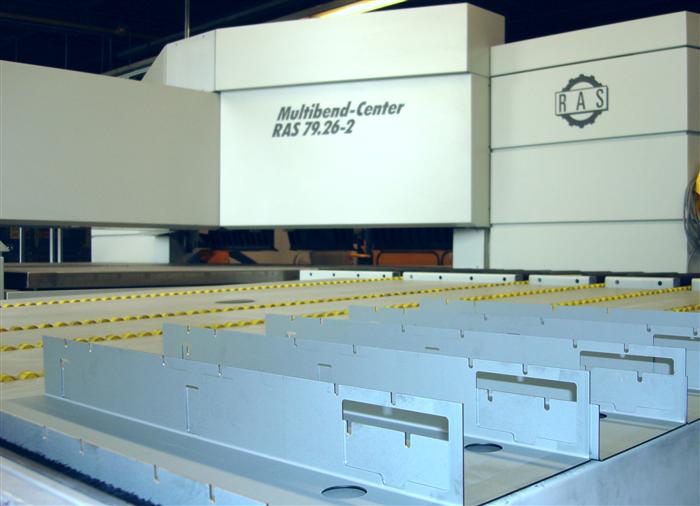

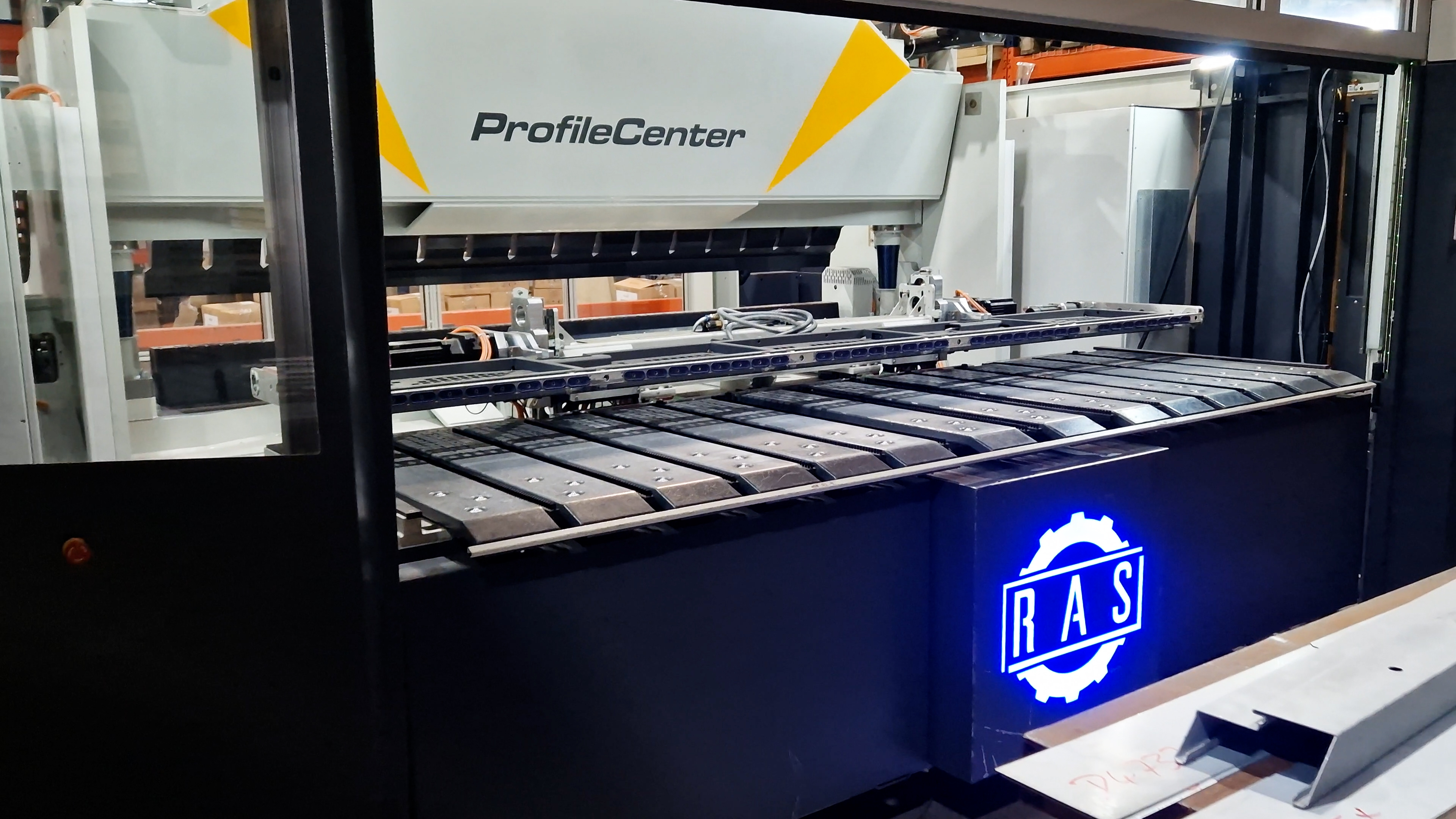

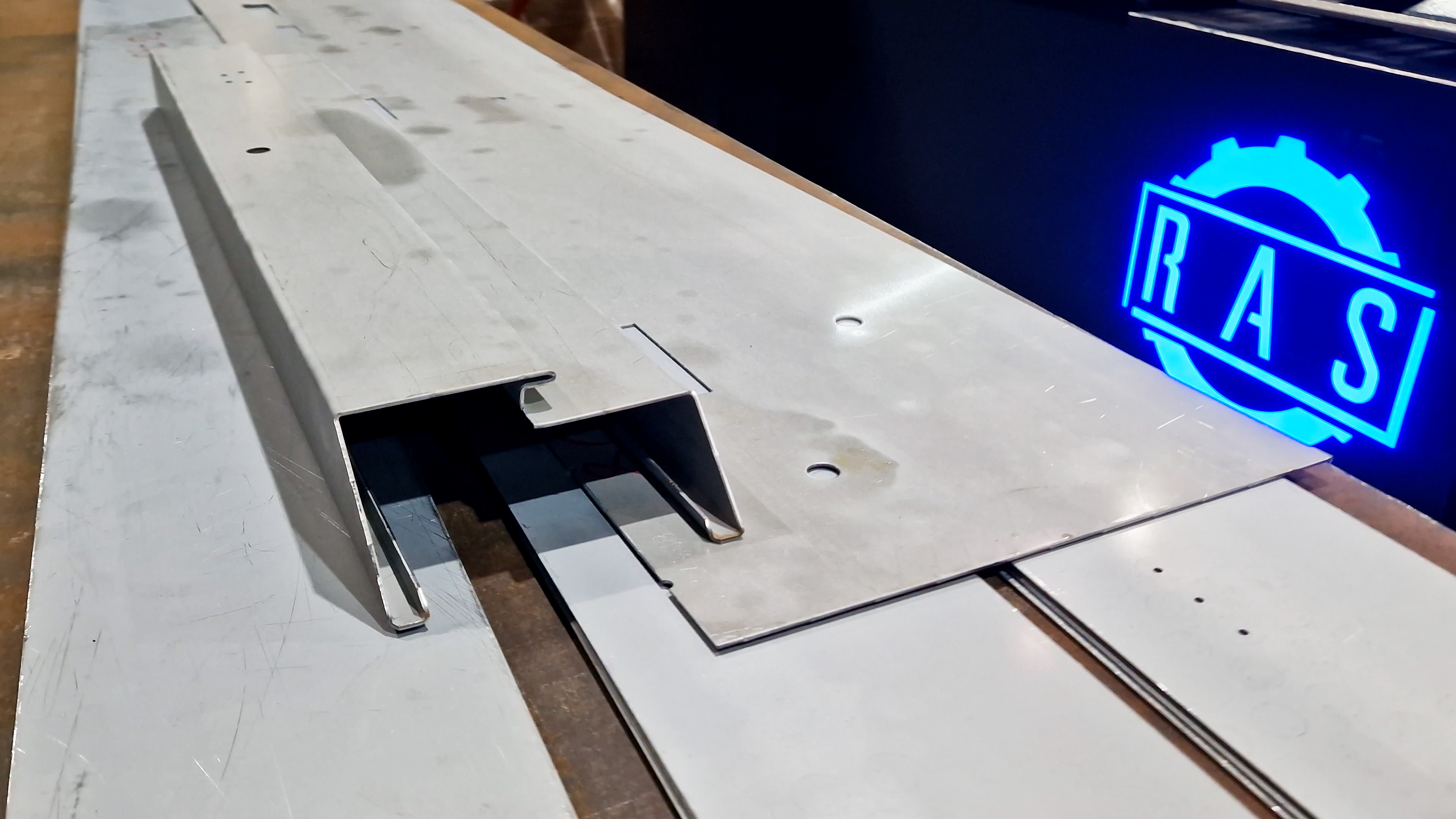

Schneider Electric is a globally active company headquartered in France. Its two main business areas are power distribution in medium and low-voltage networks and industrial automation. At its production site in Capellades near Barcelona in Spain, Schneider Electric manufactures control cabinets and distribution cabinets on highly automated systems. A poster hanging in front of a combined punching and bending line proves that automation pays off. This sheet metal processing line consists of punching modules from Pivatic and a bending cell from RAS. Schneider Electric puts the increase in efficiency through this line at 410% [more] [Video]

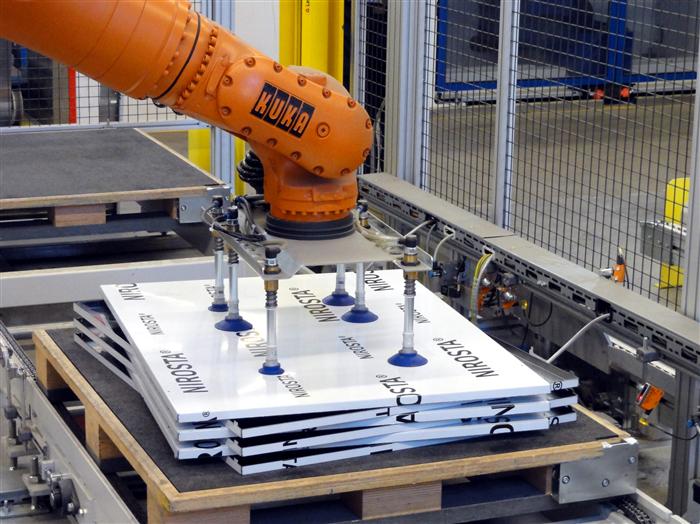

Salzmann: Speed counts

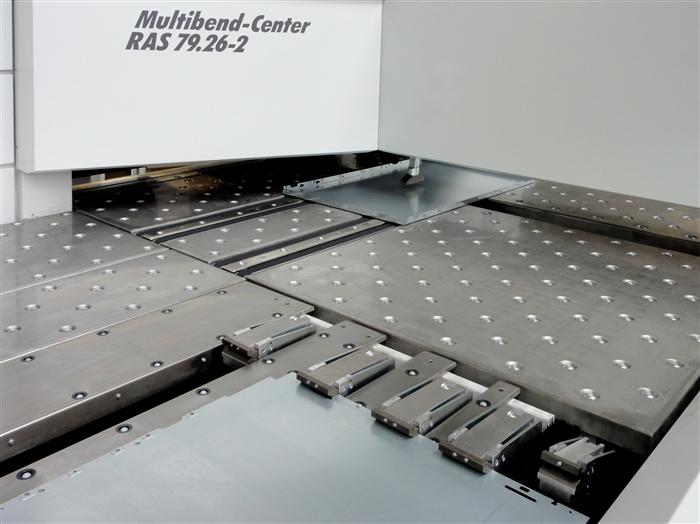

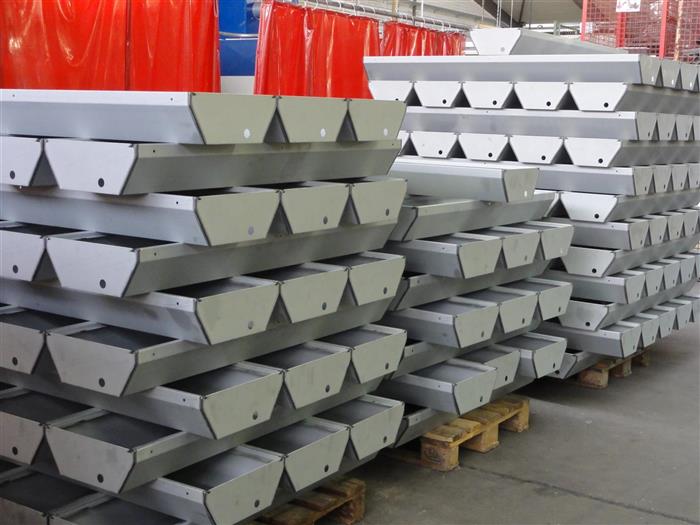

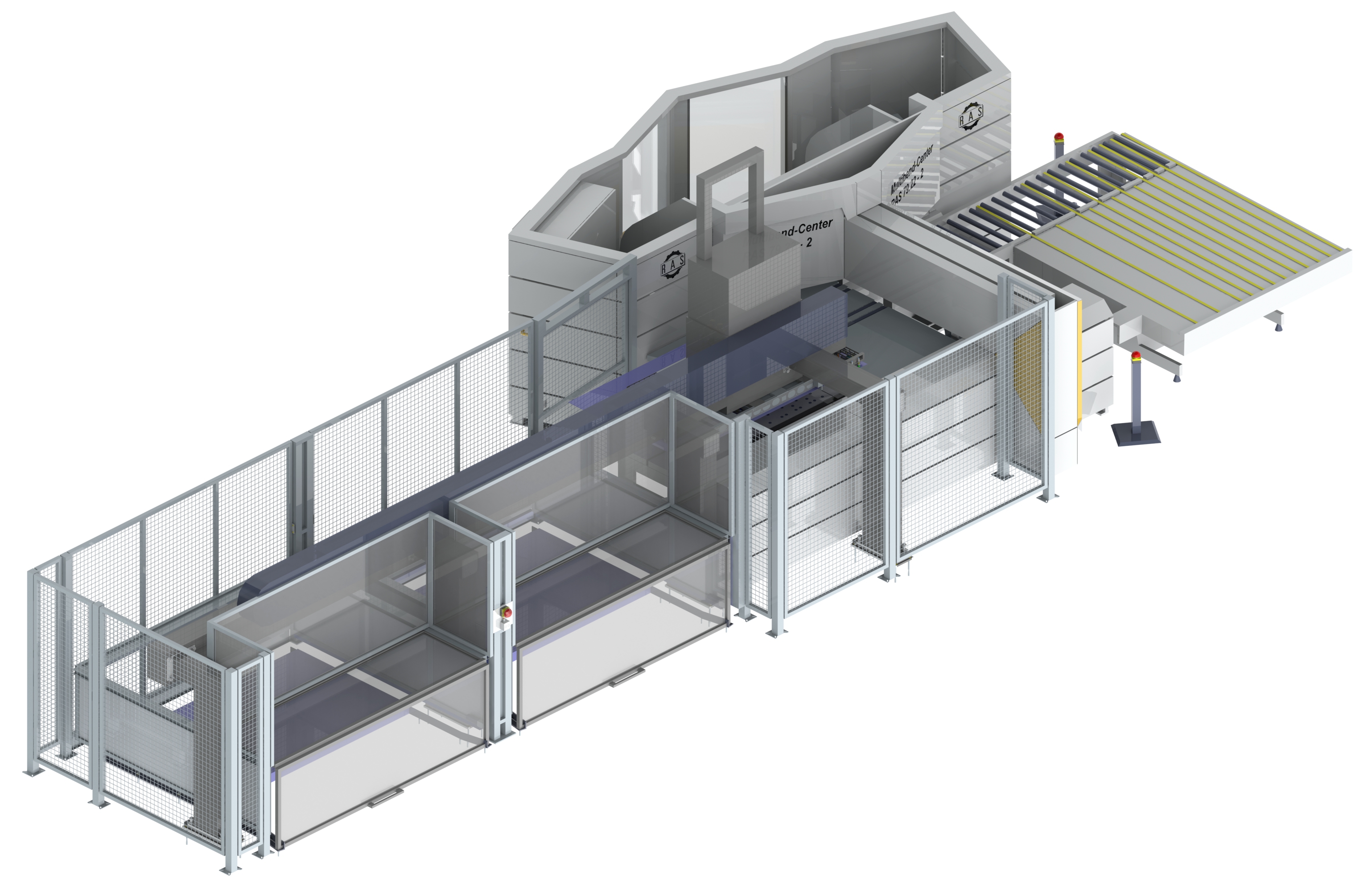

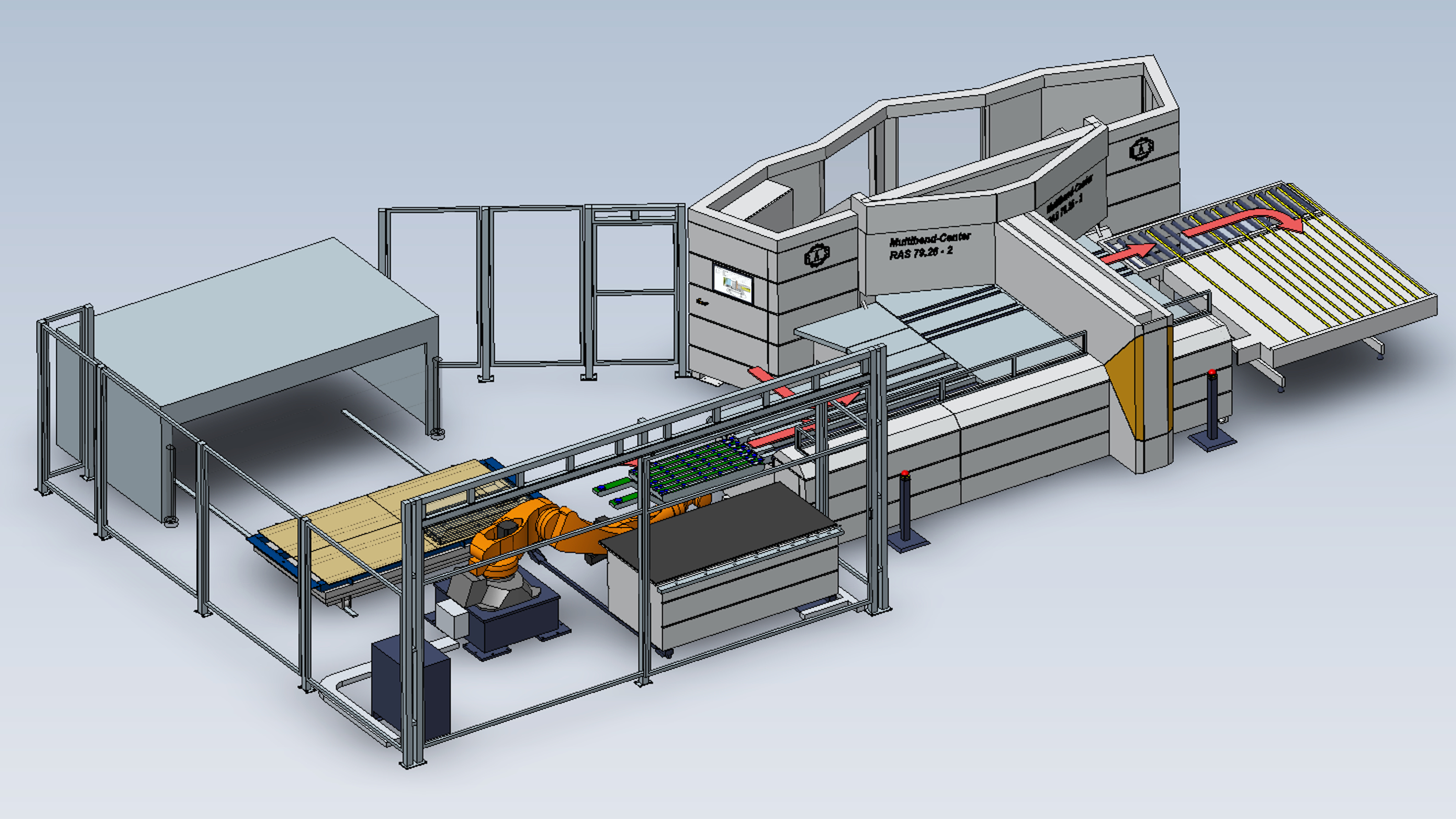

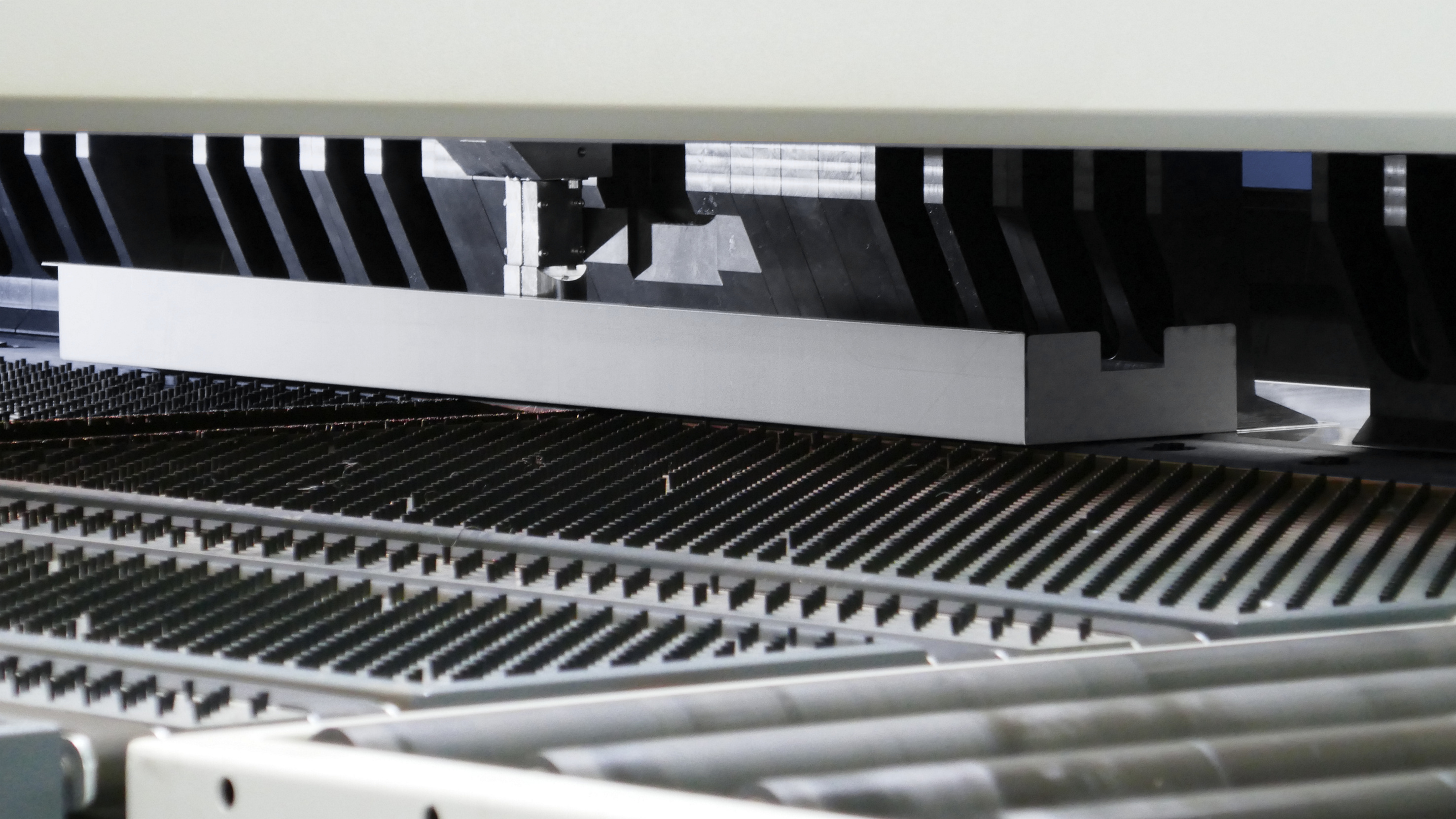

Salzmann Formblechtechnik GmbH is one of the leading job shops for sheet metal parts in the three-country region Austria-Germany-Switzerland. Two RAS bending centers are used for panels and cassettes up to 2560 mm bending length and up to 2 mm mild steel thickness. One machine is connected to a automated warehouse that provides punched blanks. An intelligent loading robot picks up the top blank from the selected stack, separates it, flips it and feeds to the panel bender. An optical scanner measures the position of the delivered blank. For maximum bending accuracy, the main manipulator positions and rotates the part with one hundredth of a millimeter positioning accuracy and one thousandth of an angular degree rotation accuracy. The bending cell folds all positive and negative flanges automatically. The Bendex Office software programs the bending sequences automatically starting from the geo data of the parts with a single mouse click. With its automation, the Multibend Center is extremely flexible and four times faster than automated press brakes. In addition, it can be operated by semi-skilled workers.

[more] [Video]

Promal: Production of high-quality metal furniture

PROMAL has been active for 35 years in design, production and marketing of high quality metal furniture for cultural institutions (bookstores, libraries, universities, museums, archives) and for the office. The company offers single elements or "turnkey" installations. In production, it relies on the performance of two RAS Multibend centers. With these bending centers, the company produces fully automated furniture elements, which are created from large-area metal parts. The well-established partnership with Alpemac is a key factor in the success and activity of the company based in Pianezza in the province of Turin. [more] [Video]

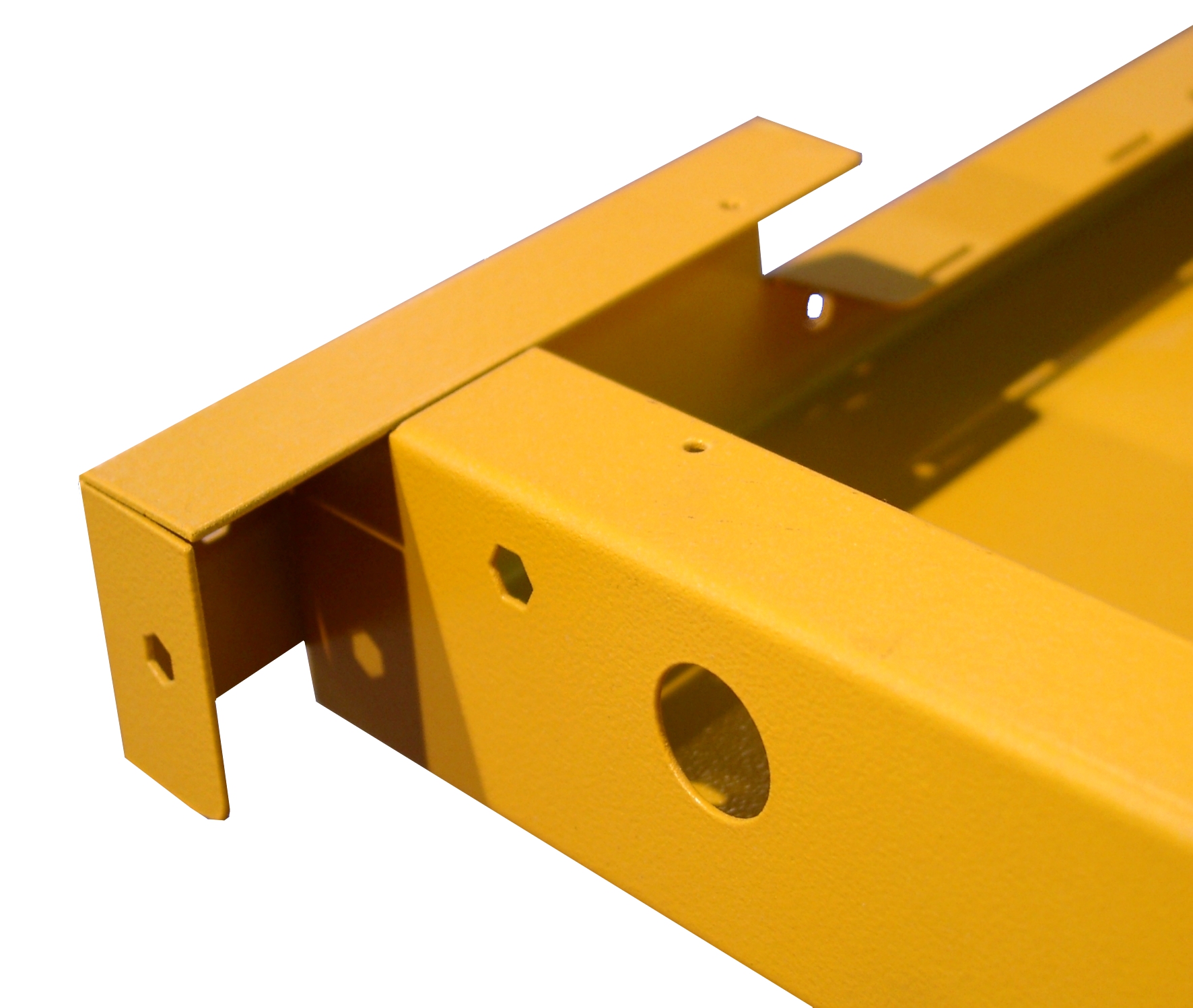

Walter Th. Hennecke GmbH: Flexible automation

Hennecke is one of the most efficient suppliers of sheet metal components and assemblies in Germany. The multitude of manufacturing technologies also includes a RAS Multibend-Center with robot blank loading. The panel bender produces medium to large batch sizes of complex sheetmetal parts with the precision and repeatability of a Swiss watch. Its skills are just as much in demand with prototypes, e.g. if a sample is to be at hand quickly and without the need of expensive special tools. "Quick cycle times, precision and costs per part are the decision factors for the use of the panel bender", explains Managing Director Klaus Dürksen and says: "Short and reliable delivery times are important criteria for our customers when choosing their supplier". Managing Director Frank Felmet adds: "Just by the automatic tool setup, we realize time savings of up to 80% compared to press brakes". [Video]

SGC: Highly Automated Production

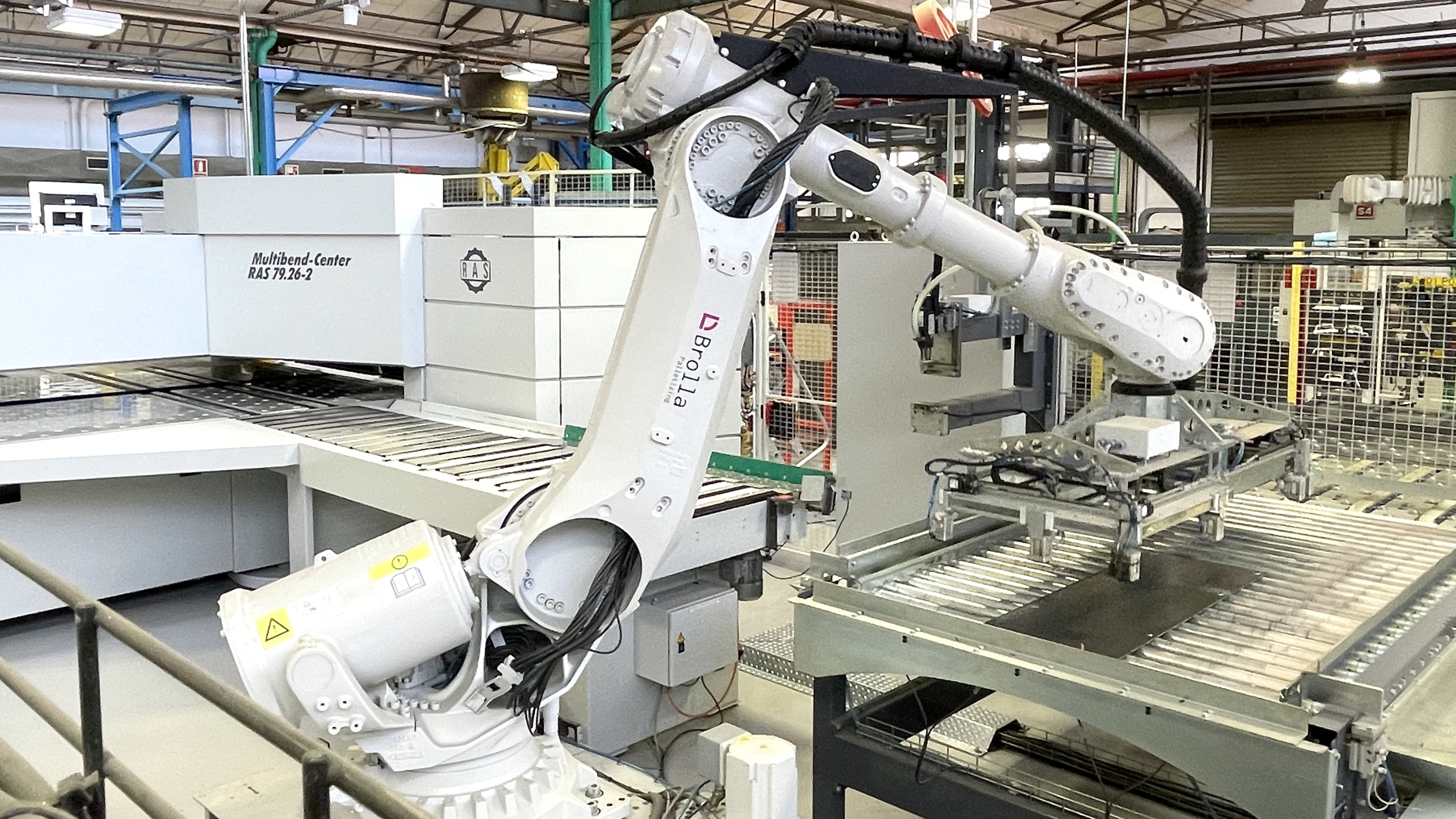

The Société Giennoise de Chaudronnerie (SGC) is a job shop for sheet metal parts equipped with state-of-the-art production machines. The company from Gien, south of Paris, relies on automation. With the RAS Multibend-Center, SGC not only operates an extremely productive bending center but has also connected this bending cell to an automated storage system and loads the blanks with their own robotic solution. [more] [Video]

Strengthening Internal Products

Döring GmbH & Co. KG comes from the field of contract manufacturing. However, today the metal specialist designs its own product ideas. Döring sells these products mainly on the Internet. With the RAS Multibend Center, Döring pairs the manufacturing capabilities of the machine with their in-house design know-how, and develop creative solutions that do not yet exist like this on the market.

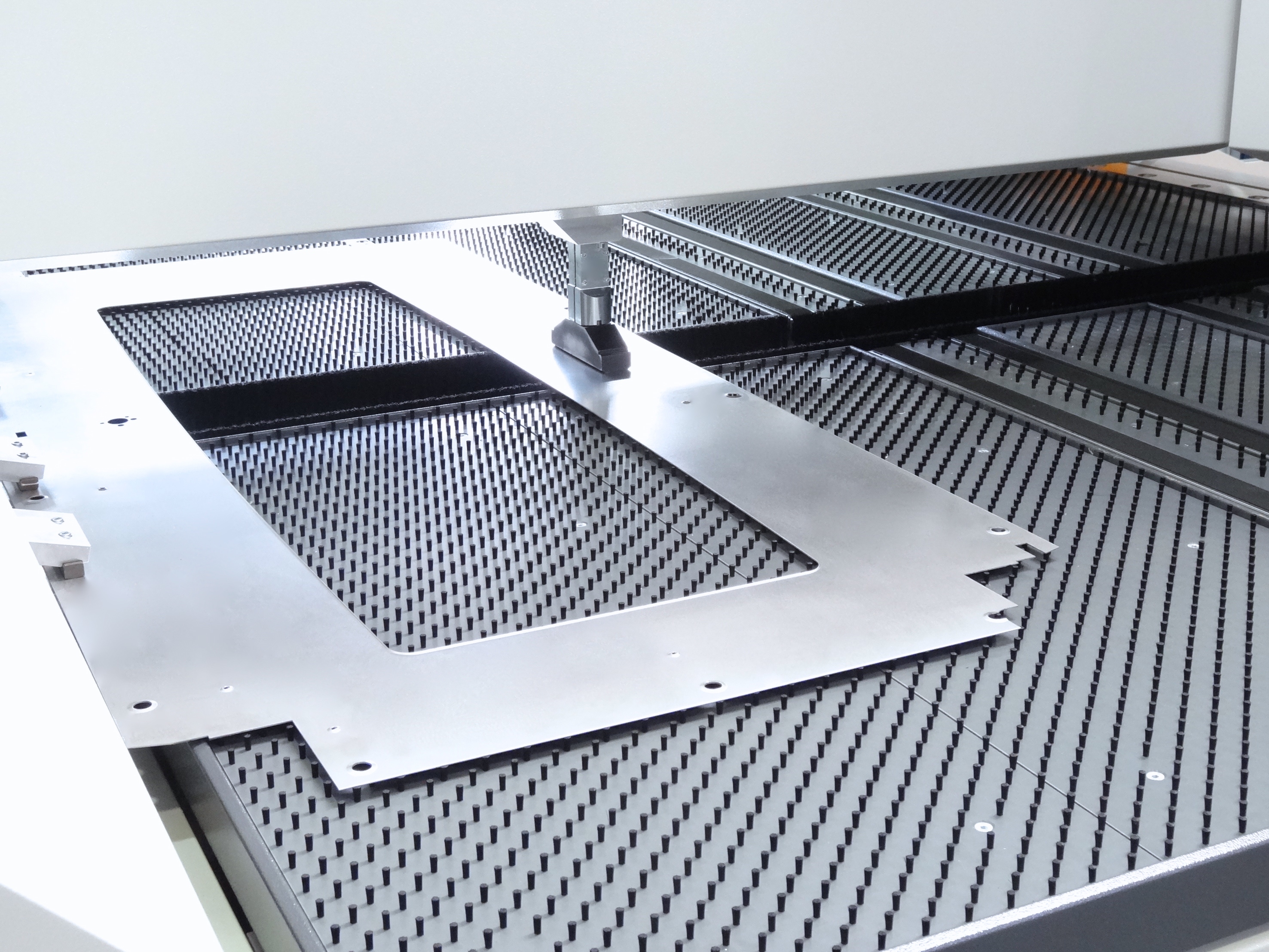

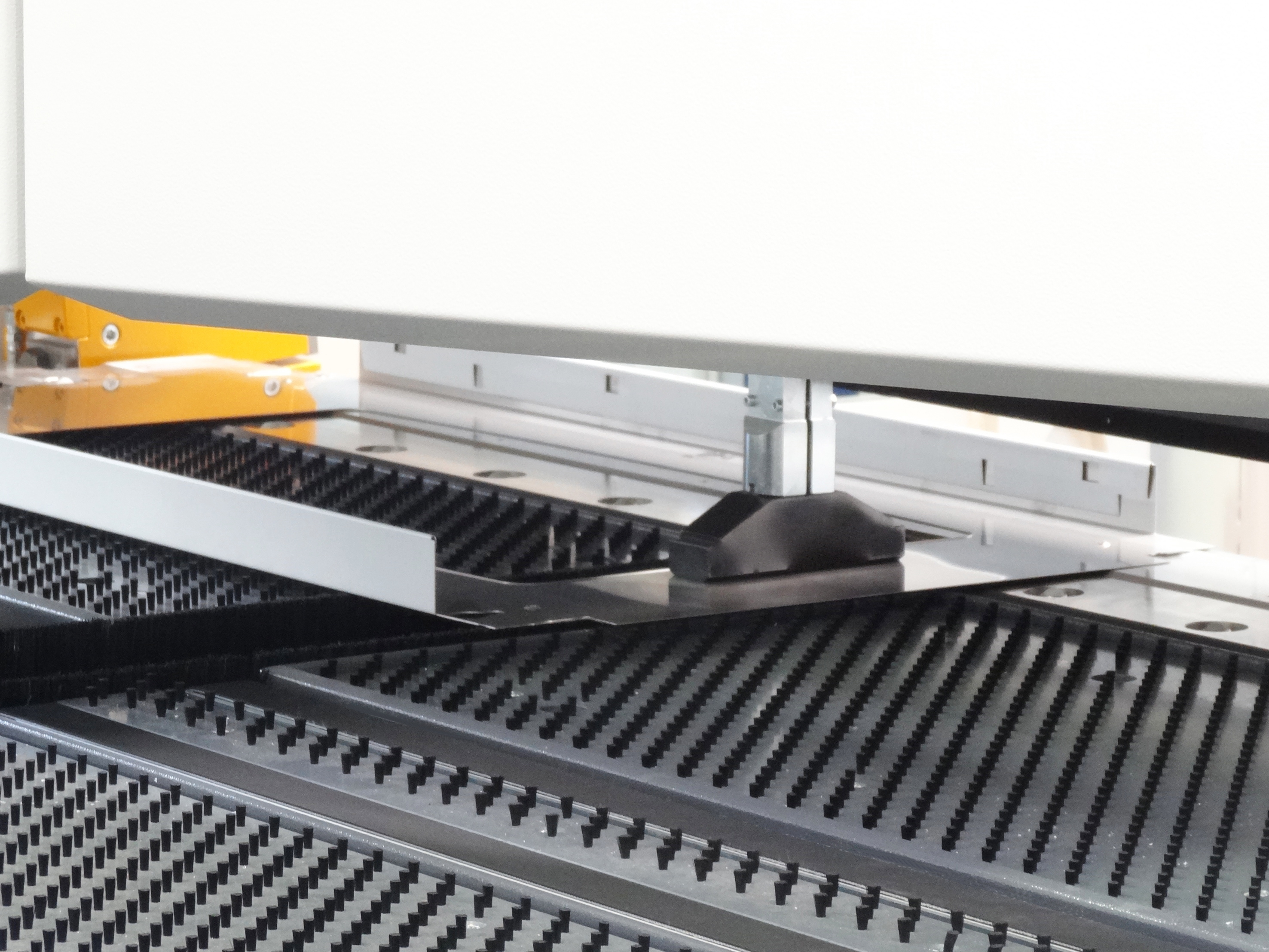

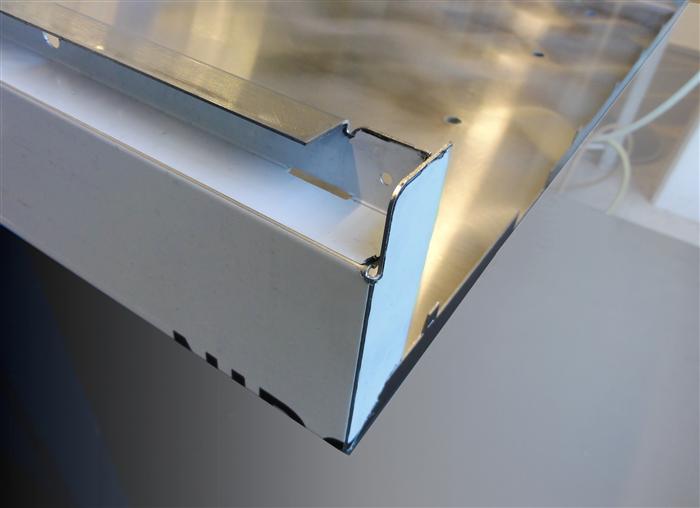

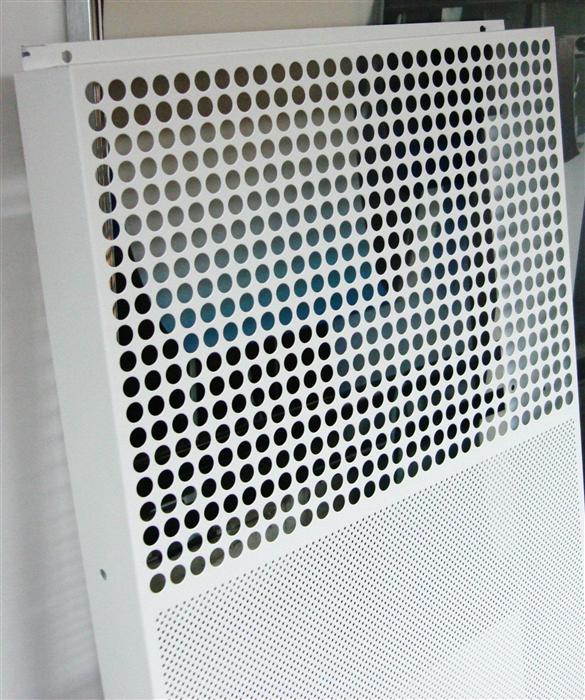

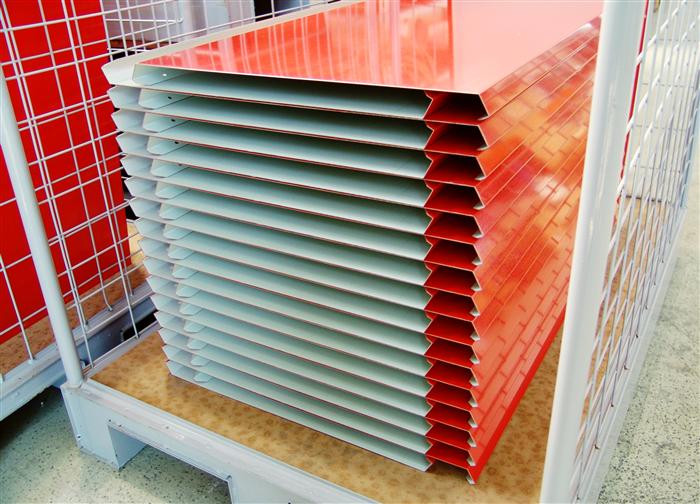

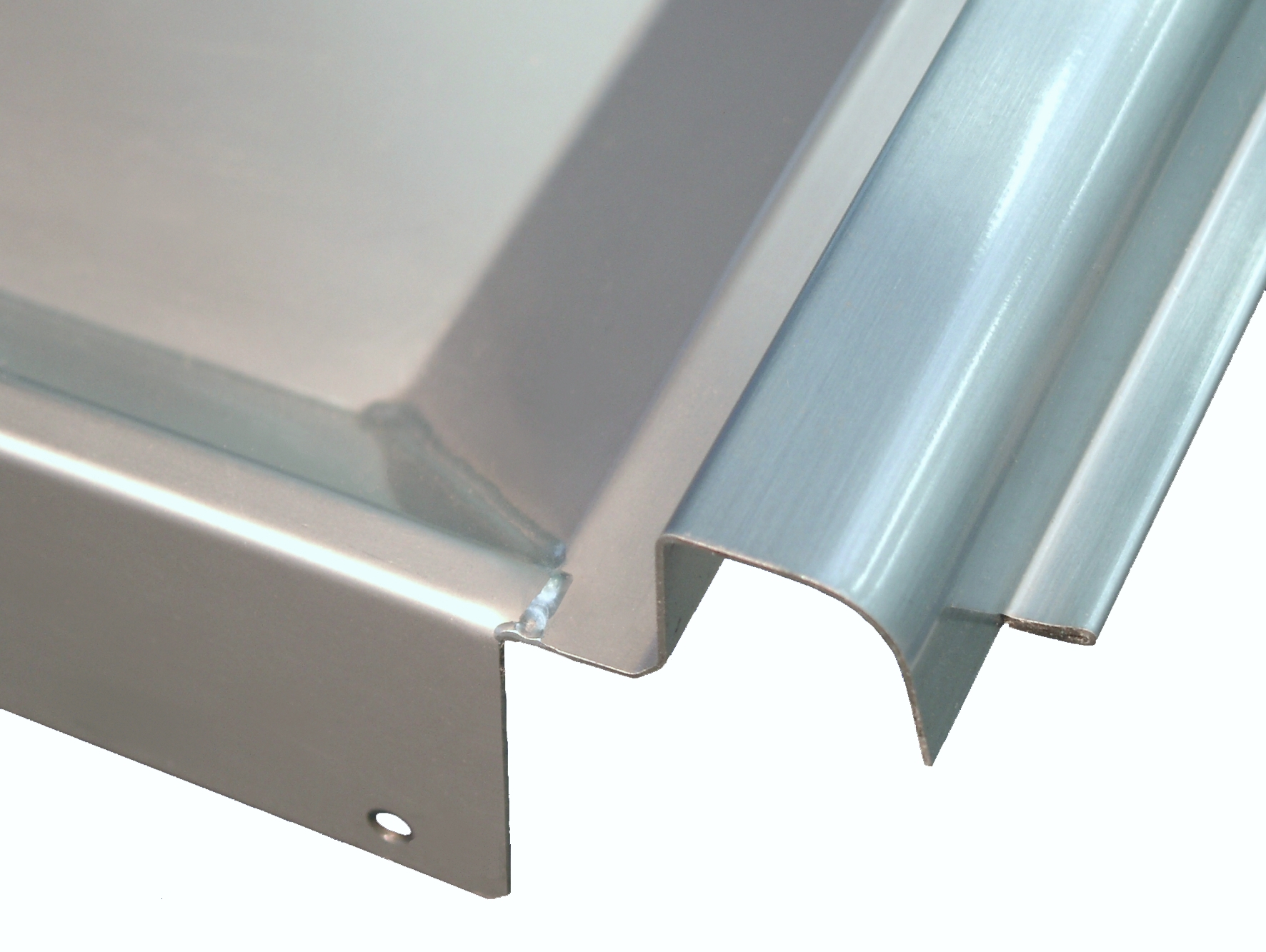

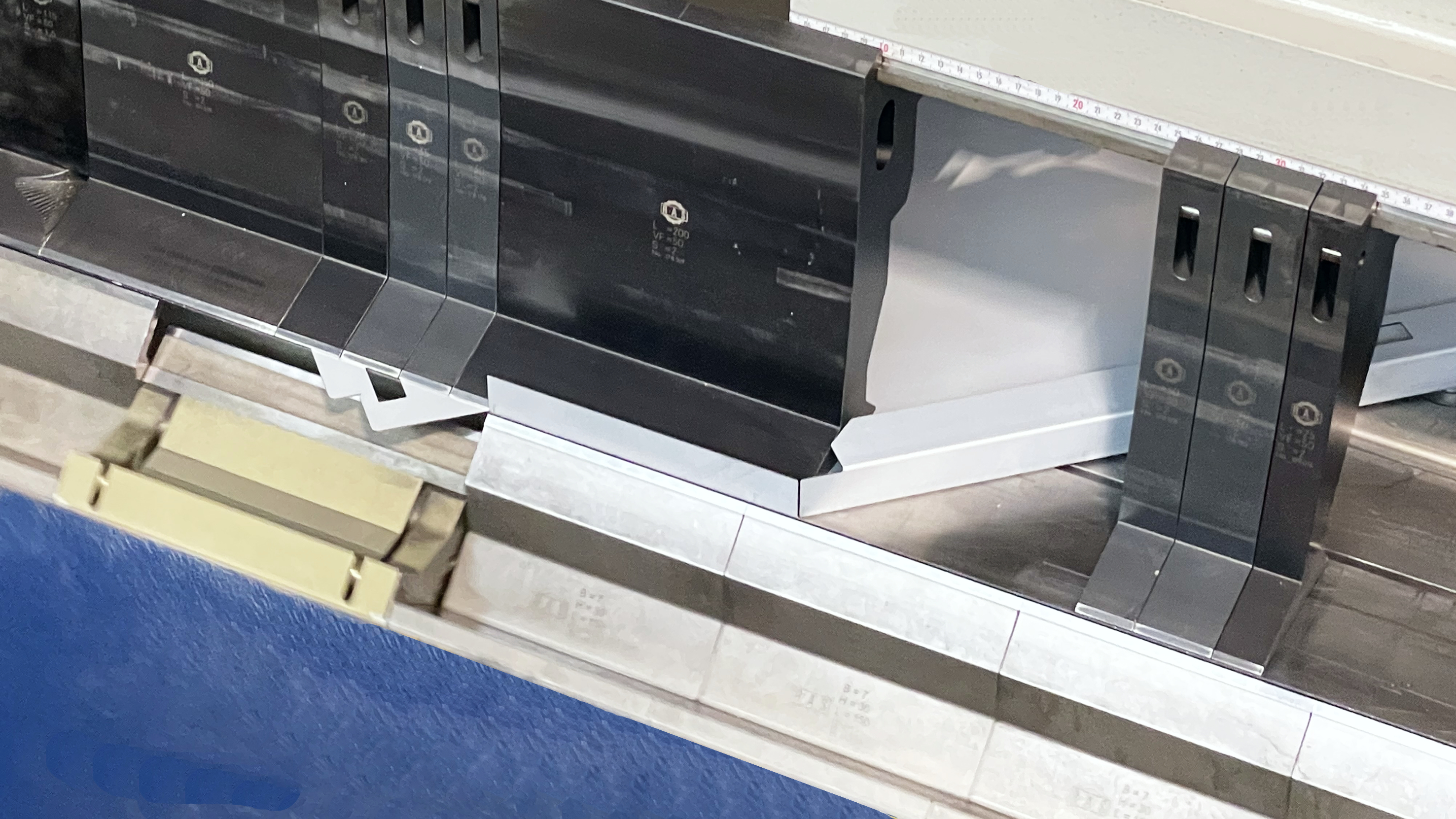

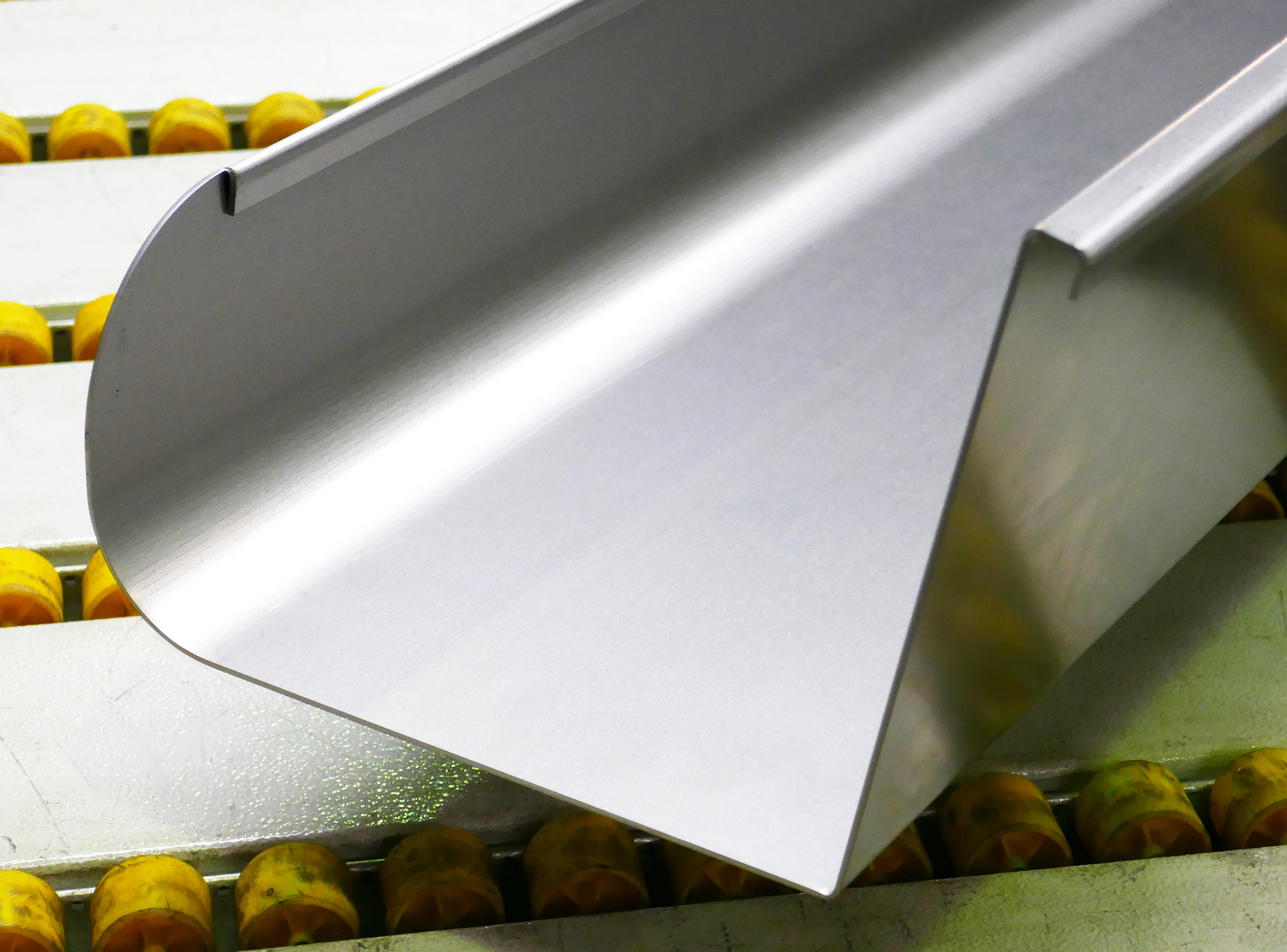

Bending of ceiling panels

Company Schmid from Simmerberg, Germany, bends ceiling panels in rectangular and special shape on the RAS 79.31-2 Multibend Center. On many parts the process starts with a STEP file. After having imported the 3D data into BendexOffice the software creates the program with a single mouseclick.

Futuristic office furniture and locker rooms

If you imagine a rattling metal structure with doors falling with clattering noise when you hear the term steel cabinet, you should have a look to the office and wardrobe cabinets of C+P Möbelsysteme GmbH & Co. KG. There you can find high-tech cabinets with features like an integrated USB charging station or electronic locking systems. Several RAS panel benders are involved in the emerging process of these cabinets.

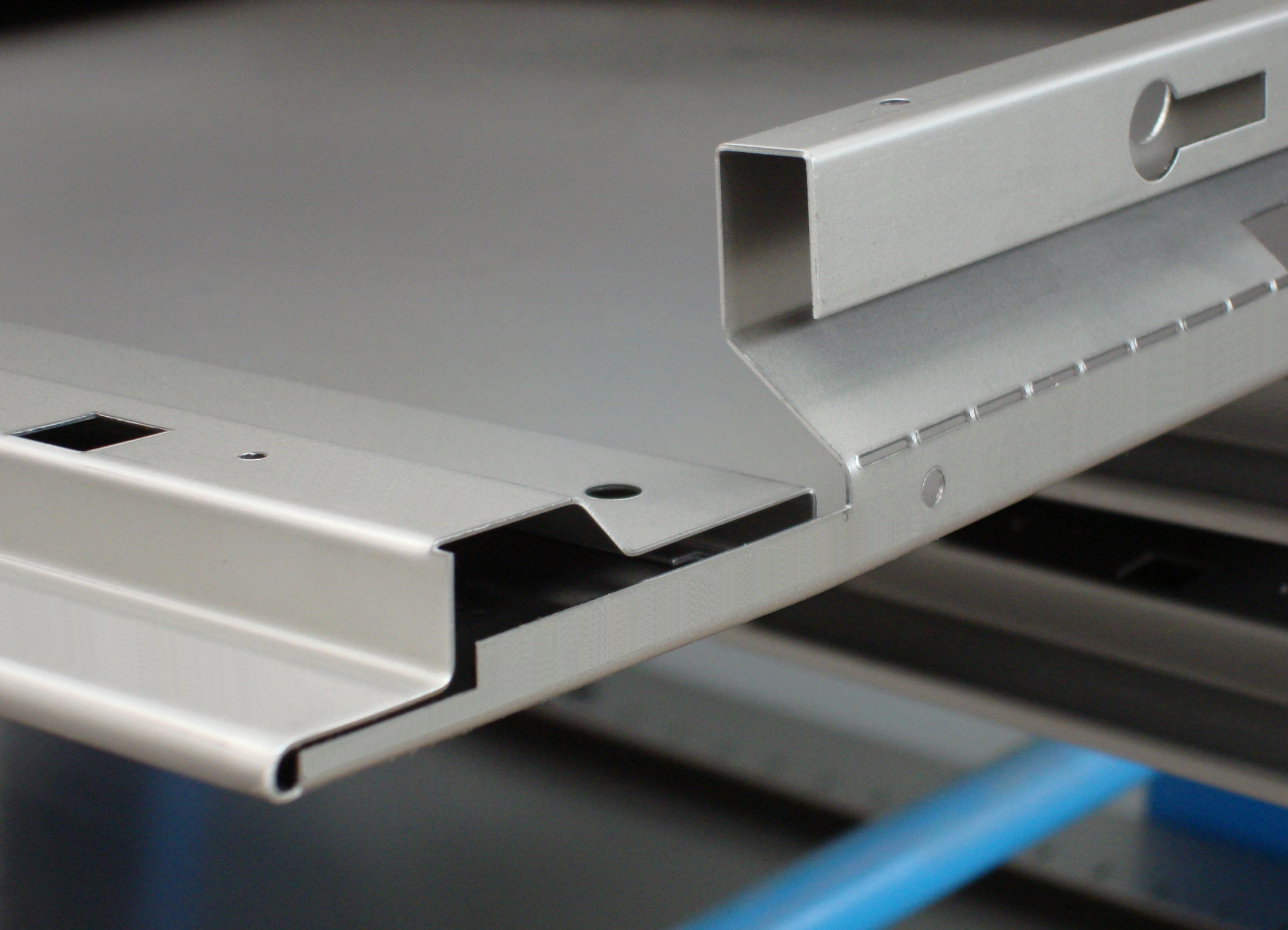

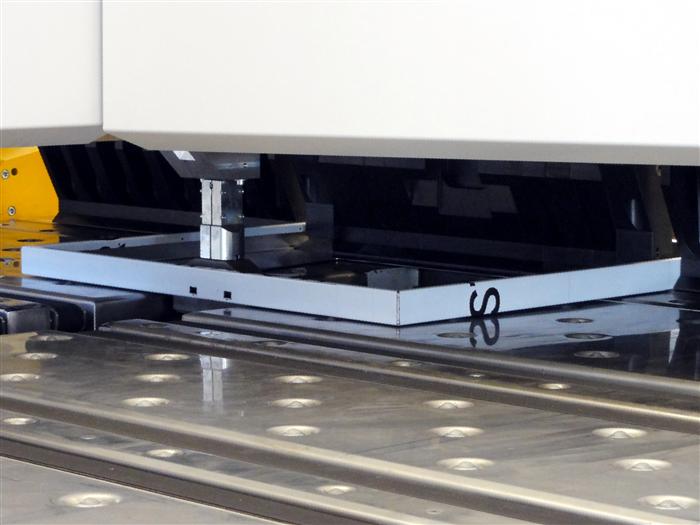

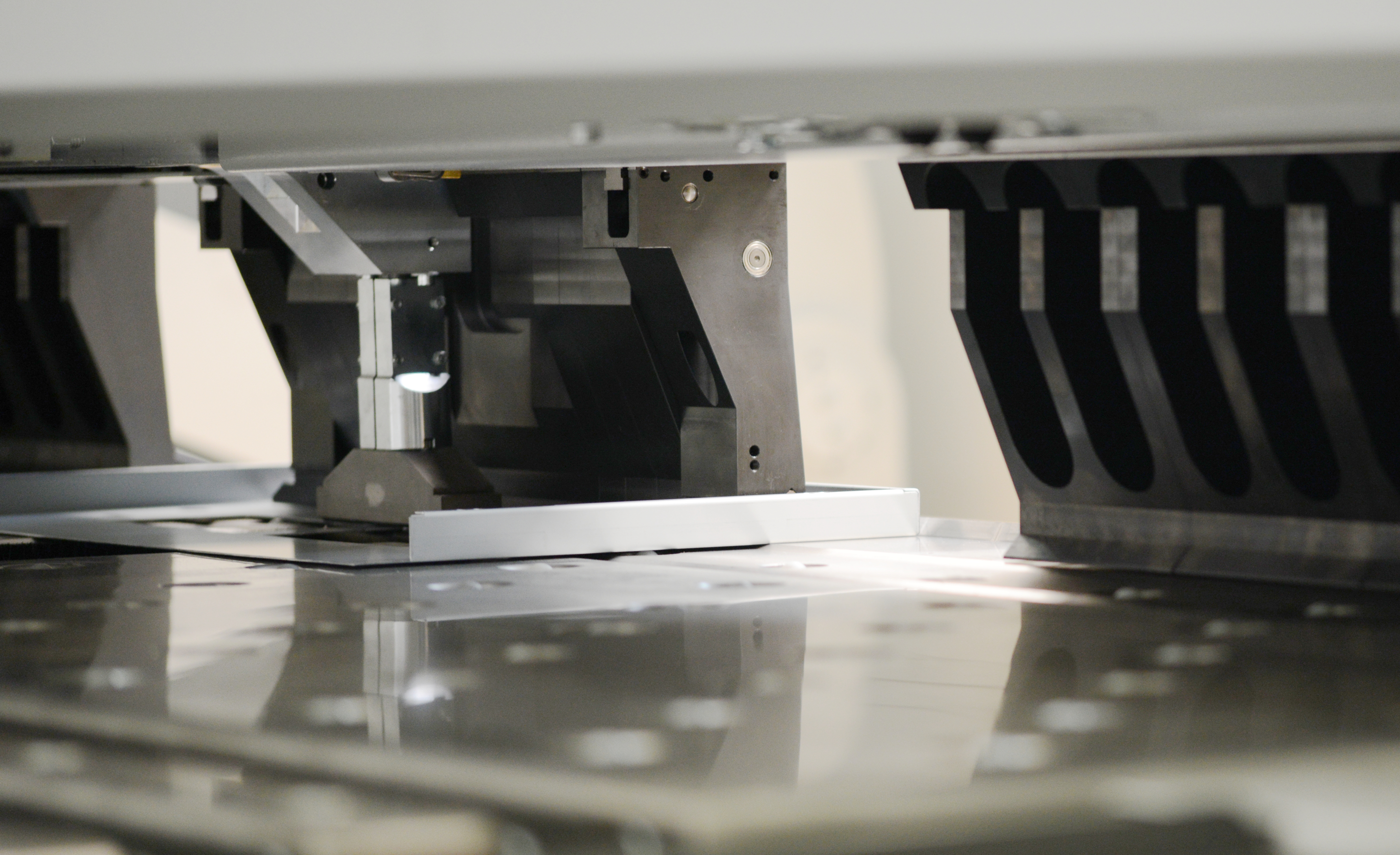

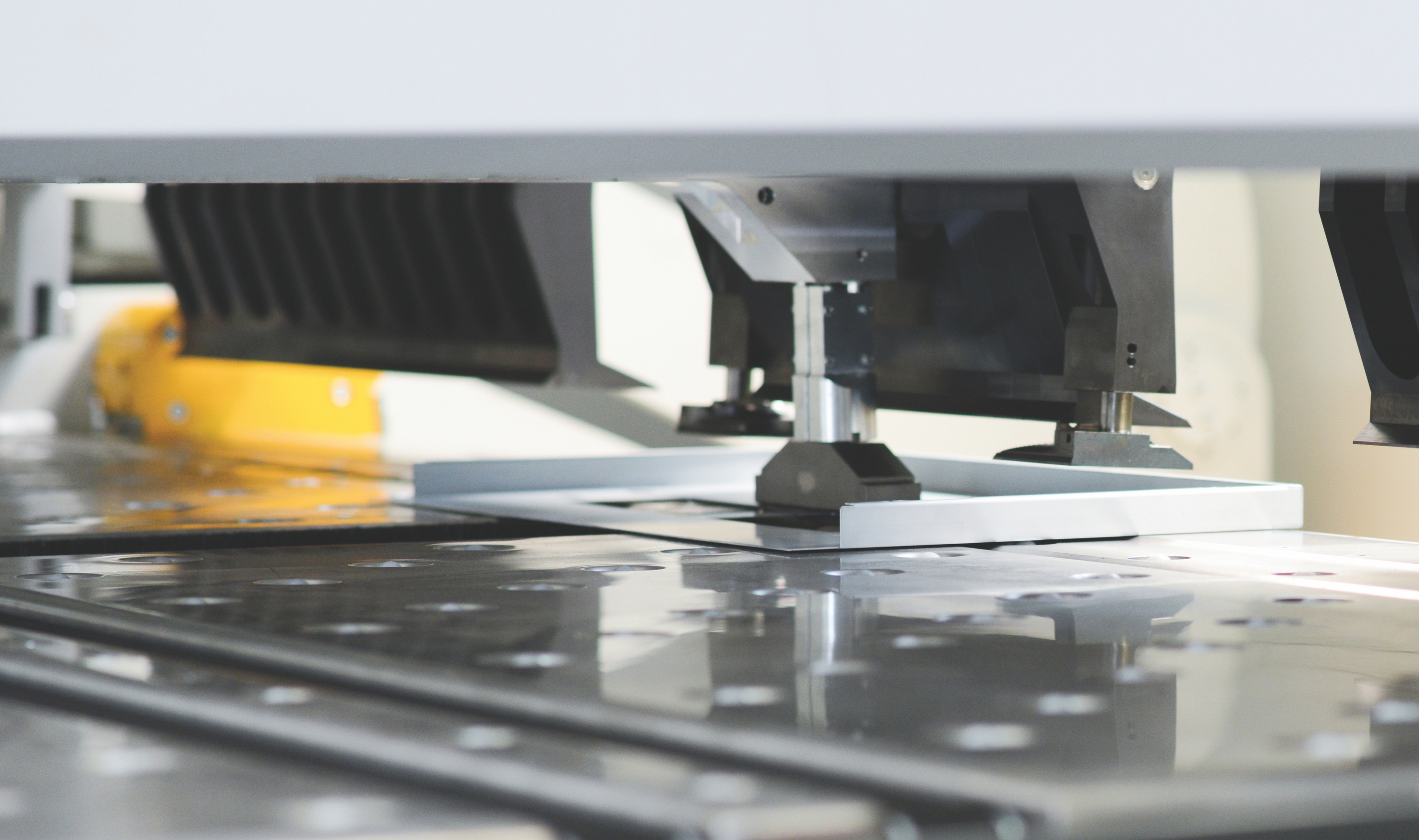

RAS panel bender at Gronbach

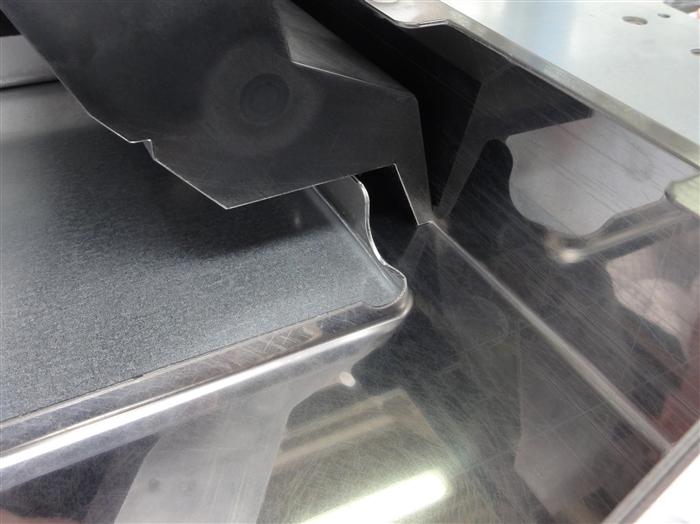

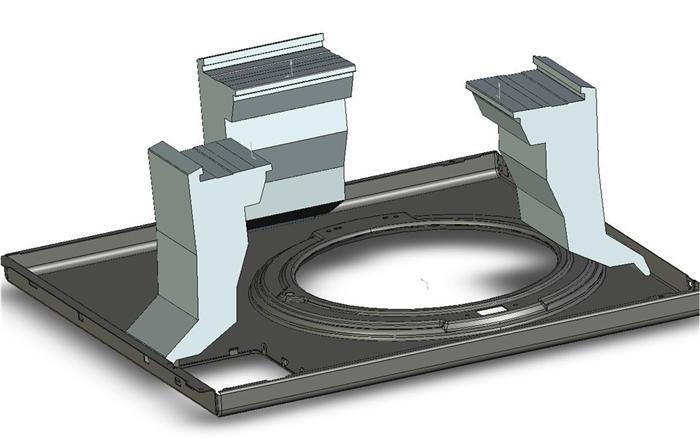

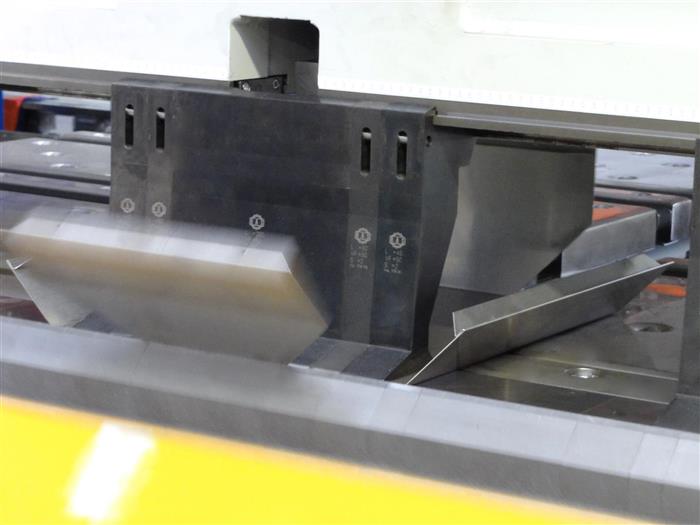

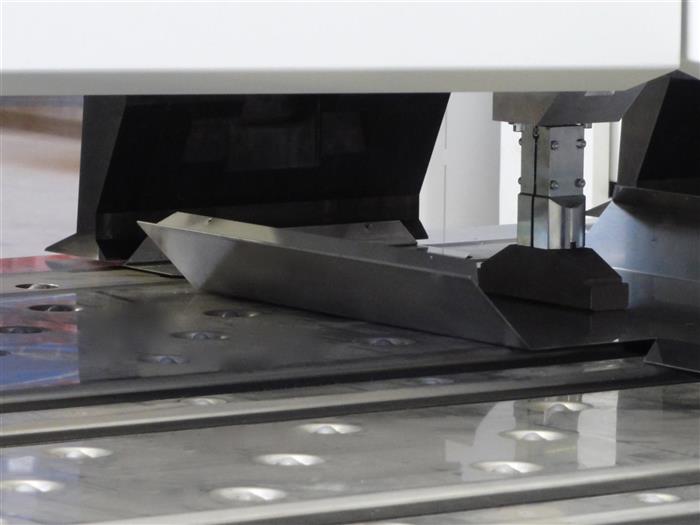

The Austrian company Gronbach produces precision sheet metal parts on a RAS Multibend-Center with a 2 station gantry loader. Due to embosses in the blank special upper beam tools are used. Many parts come with large window openings. Therefore the main manipulator has to clamp and bend the blanks off-center. As the downstream processes also incorporate TIG welding the bend results need to be extremely precise.

HVAC units from Johnson Controls

Johnson Controls from Norman, Oklahoma (USA) bends the body parts of their air conditioners on two RAS Multibend-Centers. They market their HVAC units under the brand names of York, Luxaire, Fraser-Johnston and Coleman. The panel bender automatically folds the workpieces before an operator takes the bent parts from the buffer table. Manufacturing Engineer Tom Langford is enthusiastic about the reliability and precision of the two Multibend Center.

Multibend-Center bends light fixtures at Schuch

Tradition and modernity are the hallmarks of Adolf Schuch GmbH. In 1895, when Adolf Schuch shortly after the invention of the incandescent lamp, created the first waterproof incandescent light bulb fitting, no one could have dreamed how the company nowadays produces its special light fixtures. With state-of-the-art production technologies, including a RAS Multibend Center panel bender, the 350 people company has earned a reputation as one of the leading suppliers of technical luminaires of higher protection categories.

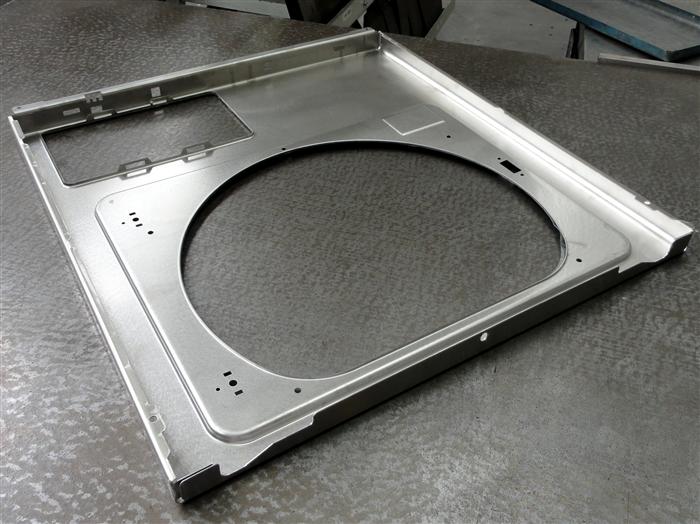

Multibend-Center bends steam ovens

Convotherm Elektrogeräte GmbH produces combi steam ovens. Since 2008, the company based south of Munich, has been manufacturing the housing components of its eleven oven models on the RAS Multibend Center panel bender. The target for the investment was a flexible production system matching the assembly sequence of the cookers.

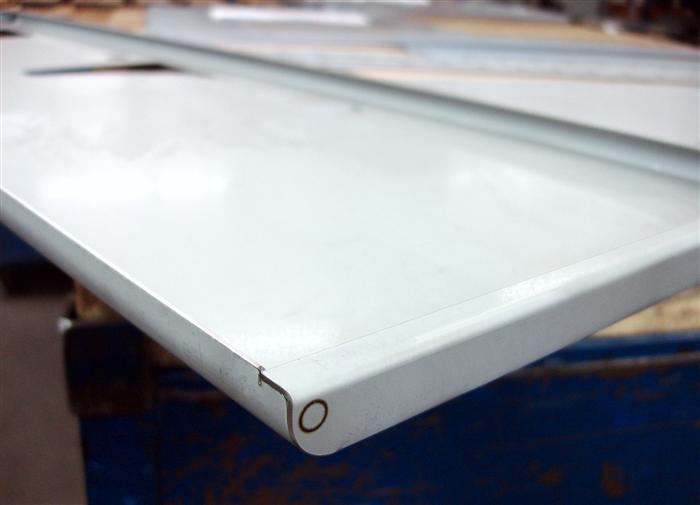

Multibend-Center at Miele

An investment in a panel bender might have many different reasons. While most companies just look for more productivity in metal bending, other producers use a more global approach. One of these companies is Miele & Cie. KG in Lehrte near Hanover. Short cycle times were not their main focus for the RAS Multibend-Center investment. Issues like fast machine set-ups, a multifunctional tool set, high levels of part design flexibility and system reliability as well as improved logistic sequences have been much more important.

Job shop: Glomb

The company Blechbearbeitung Glomb is based in Pinneberg, Germany. Today, the fabrication specialist employs 60 people. Glomb provides competent consulting in all aspects of sheet metal processing to his customers and therefore strongly contrasts with the wide range of general job shops. A RAS Multibend-Center panel bender with robotic blank loading complements the already wide range of production capabilities.

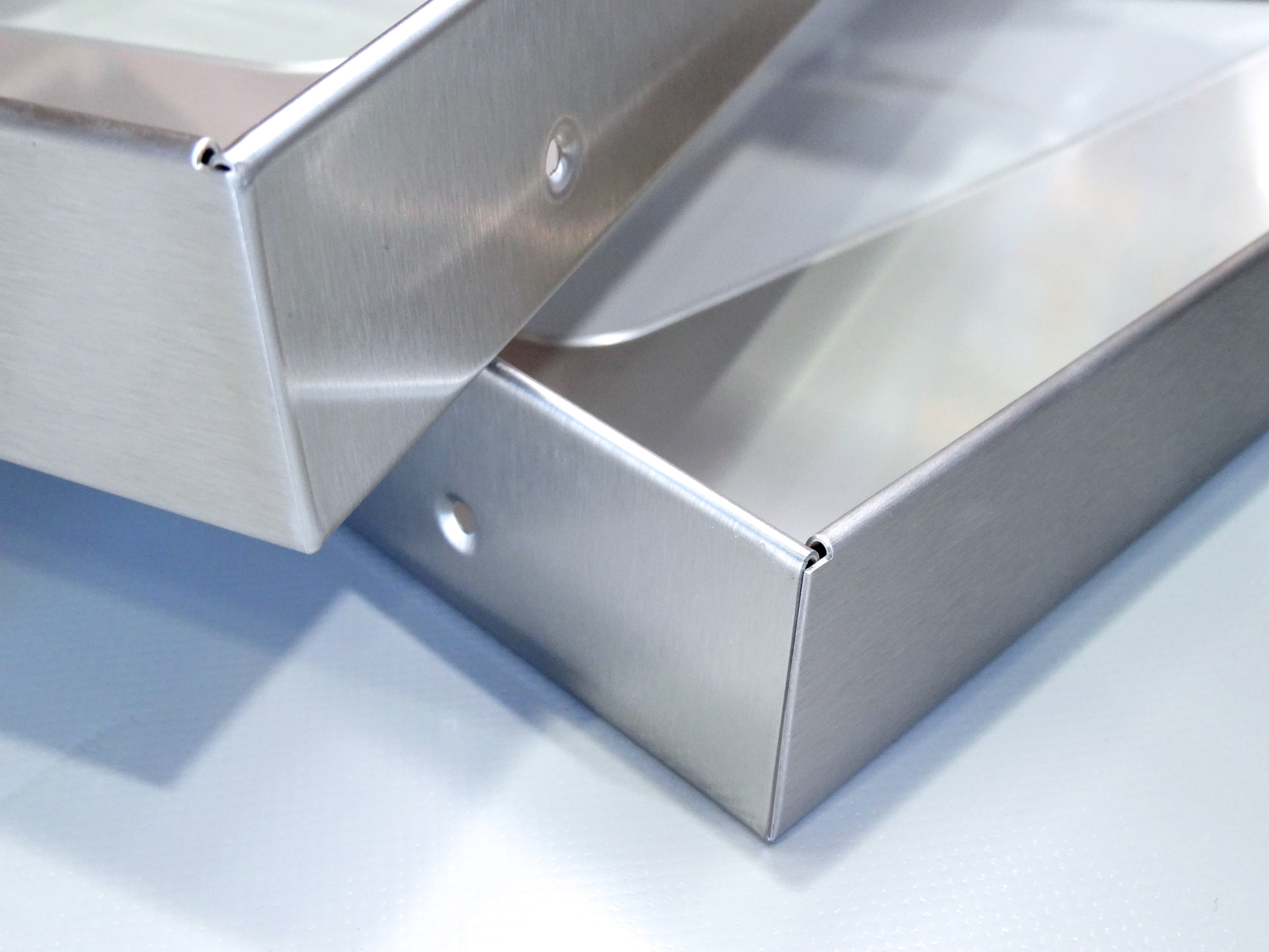

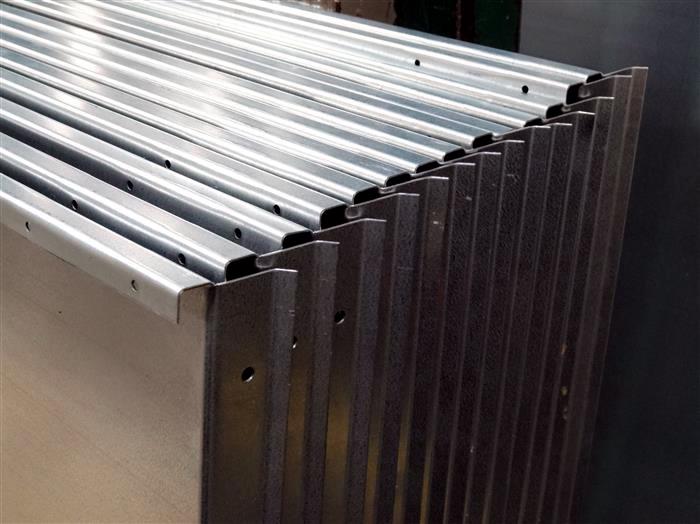

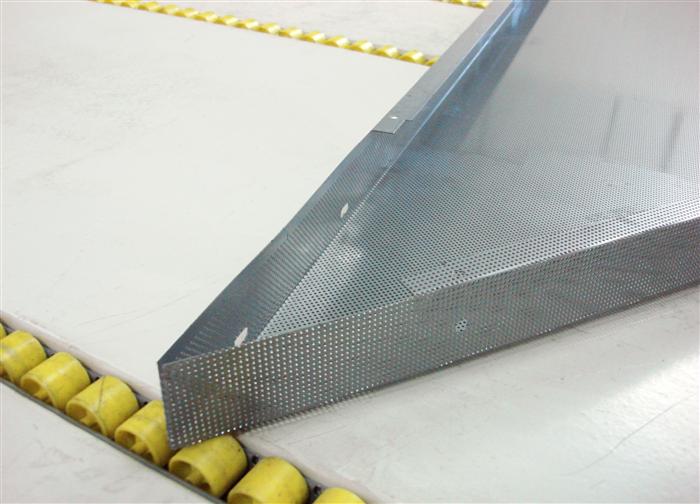

SAS: Metal ceilings

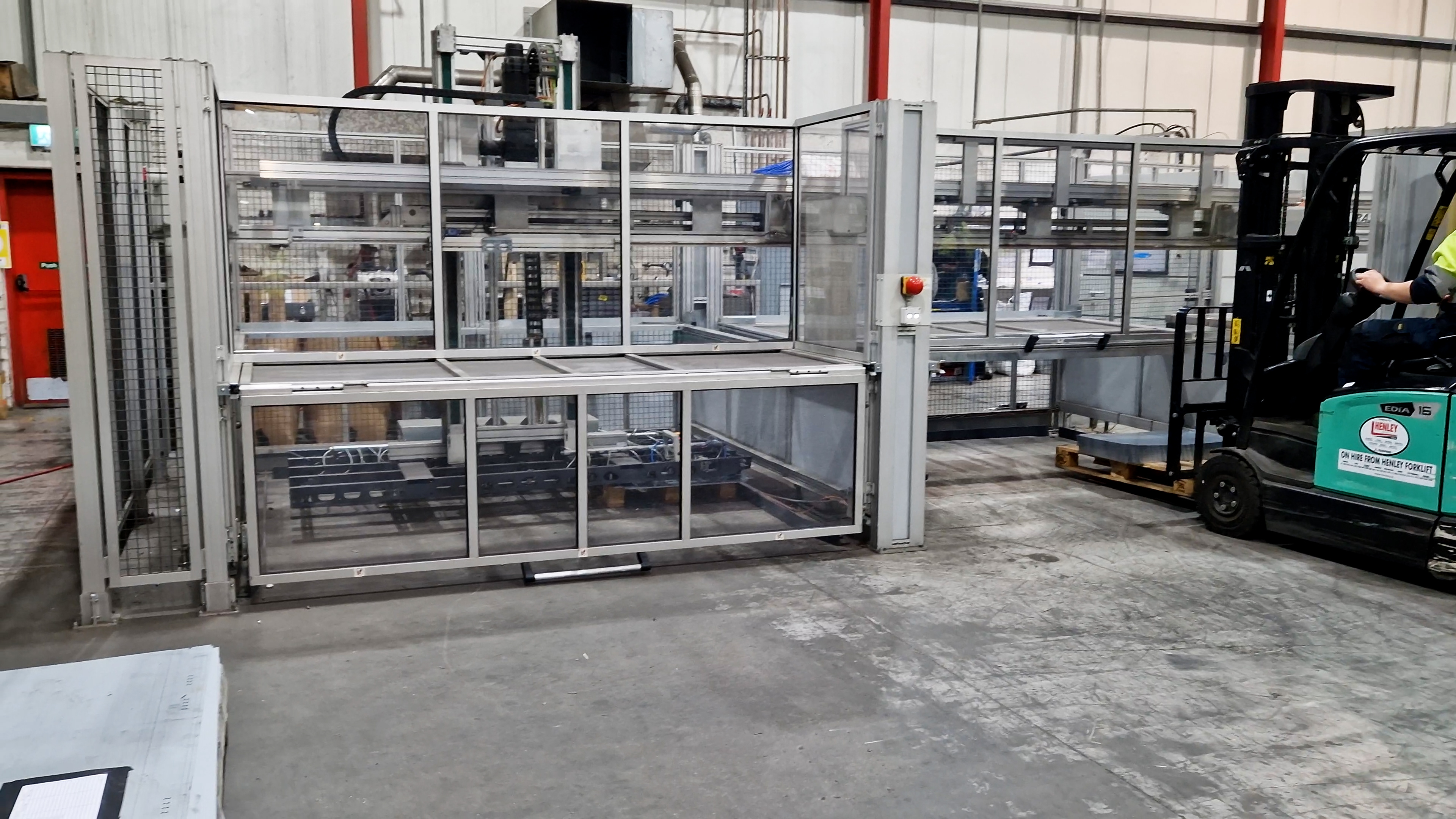

SAS International is a world leader in the design and manufacture of precision engineered metal systems for suspended ceilings. The SAS UK manufacturing facilities rank amongst the most modern and fully equipped in the world. The Bridgend facility in South Wales manufactures ceiling tiles, and heating and cooling elements. Maybole in Scotland is responsible for special architectural metalwork. In 2007 SAS improved their production capabilities adding three automated folding systems RAS Multibend-Centers.

Hargassner: Heating systems

On the Hargassner shop floor space is limited. The pallet oven specialist therefore requested a special solution with an intelligent loading and unloading robot for the production of their boiler trims. The blanks are provided by a Stopa storage system and the robot can pick and load blanks from up to 4 different stacks of material without a need of being programmed. The unloading robot stacks the finished parts on pallets and also calculates its movements fully automated.

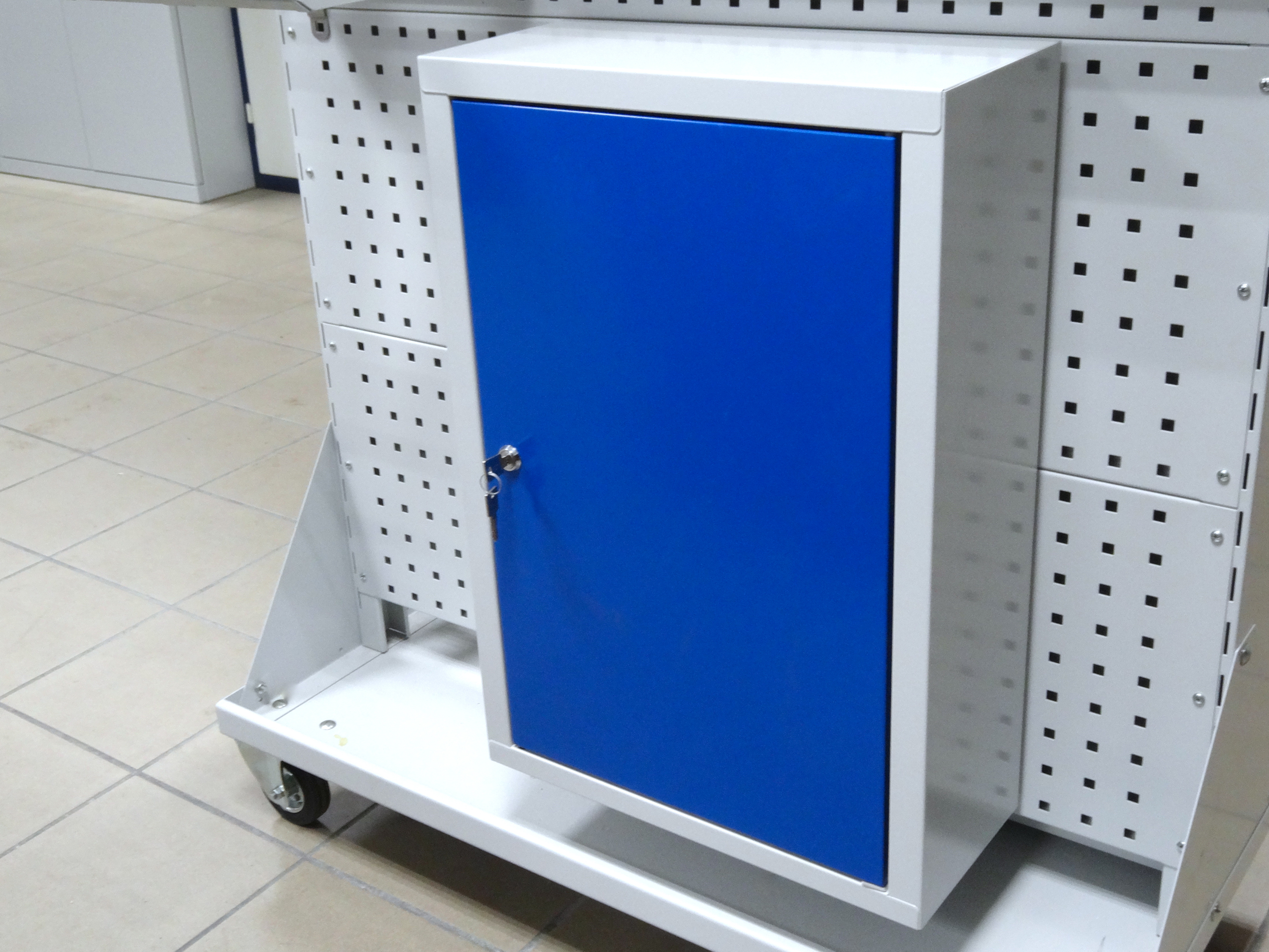

Bedrunka & Hirth: Three into one!

Just like every company throughout the world, the German company Bedrunka & Hirth, must make its products faster, better and less expensively to be competitive in the European market. The RAS Multibend-Center panel bender not only processes their parts faster, but also allows many product redesigns with fewer components.

Henke: Semi-finished also creates profit

Karl Hermann Wolf is proud, that his enterprise, located in the German town Altenstadt, has been a supplier to international well-known companies for many years. But more and more he has had to deal with foreign competitors. Therefore he decided to invest in a fully automated RAS Multibend-Center.

![[Translate to english:] Beladeseite des Biegezentrums RAS 79.31-2 [Translate to english:] Beladeseite des Biegezentrums RAS 79.31-2](/fileadmin/images/produkte/biegen/multibend-center_7931-2/anwendung/7931-2_Beladeseite_3.jpg)

![[Translate to english:] Manuelles Beladen von Lochblech [Translate to english:] Manuelles Beladen von Lochblech](/fileadmin/images/produkte/biegen/multibend-center_7931-2/anwendung/Beladen_Lochblech.jpg)

![[Translate to english:] Auslaufseite für fertige Deckenpaneele [Translate to english:] Auslaufseite für fertige Deckenpaneele](/fileadmin/images/produkte/biegen/multibend-center_7931-2/anwendung/7931-2_Auslaufseite_4.jpg)

![[Translate to english:] Gelochte Rechteckpaneele [Translate to english:] Gelochte Rechteckpaneele](/fileadmin/images/produkte/biegen/multibend-center_7931-2/anwendung/Deckenkassetten.jpg)

![[Translate to english:] Schrägwinklige Deckenkassetten [Translate to english:] Schrägwinklige Deckenkassetten](/fileadmin/images/produkte/biegen/multibend-center_7931-2/anwendung/Deckenkassette_schraeg_Einlegen.jpg)

![[Translate to english:] Spitz zulaufende Deckenkassetten [Translate to english:] Spitz zulaufende Deckenkassetten](/fileadmin/images/produkte/biegen/multibend-center_7931-2/anwendung/Deckenkassette_schraeg_Detail_1.jpg)