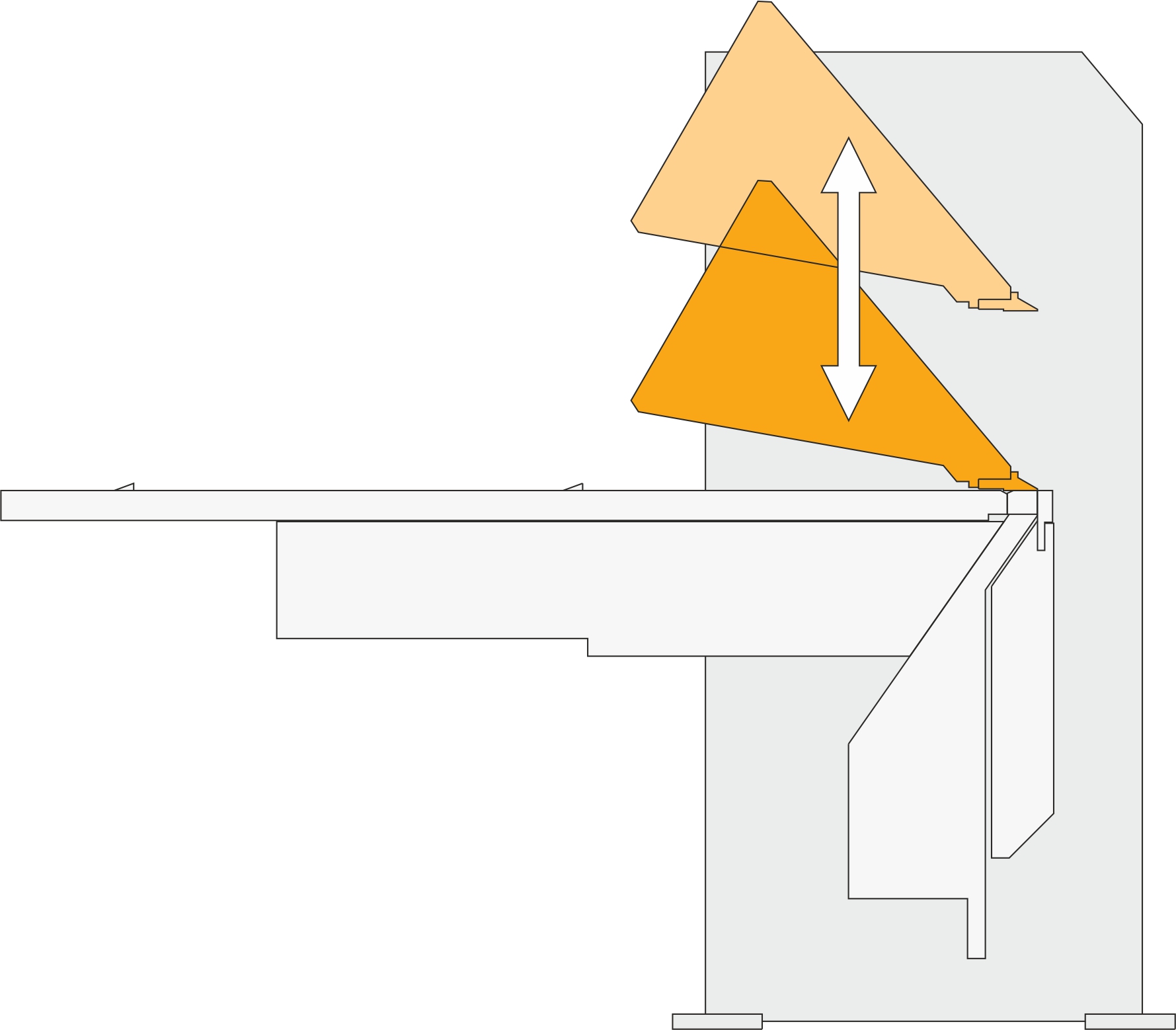

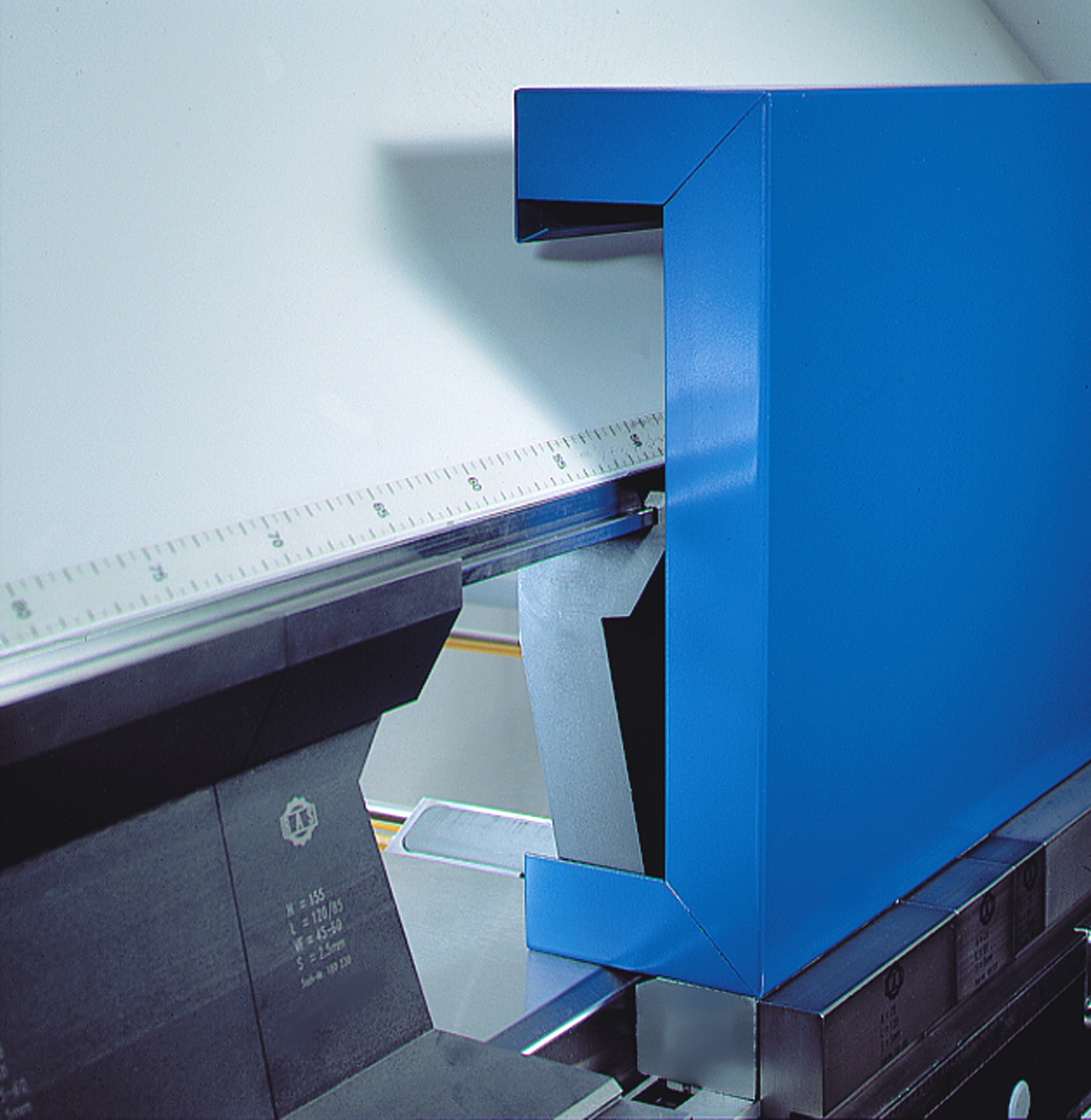

Upper beam

The upper beam impresses with large open spaces in front of and behind the beam. The tools are clearly visible to the operator when working on large parts from the rear. As the tool seat automatically clamps the tools, the set-up is done in no time.

- Fast movements for closing/opening

- Hemming: closed, open, tear-drop hems

- Large free space in front of the upper beam (part design flexibility)

- Rigid upper beam for straight bends

- Long and deep guiding system (excellent bend results)

- Housed spindle in a sealed oil bath (low maintenance)

- Normal and reduced speed (part positioning at marks

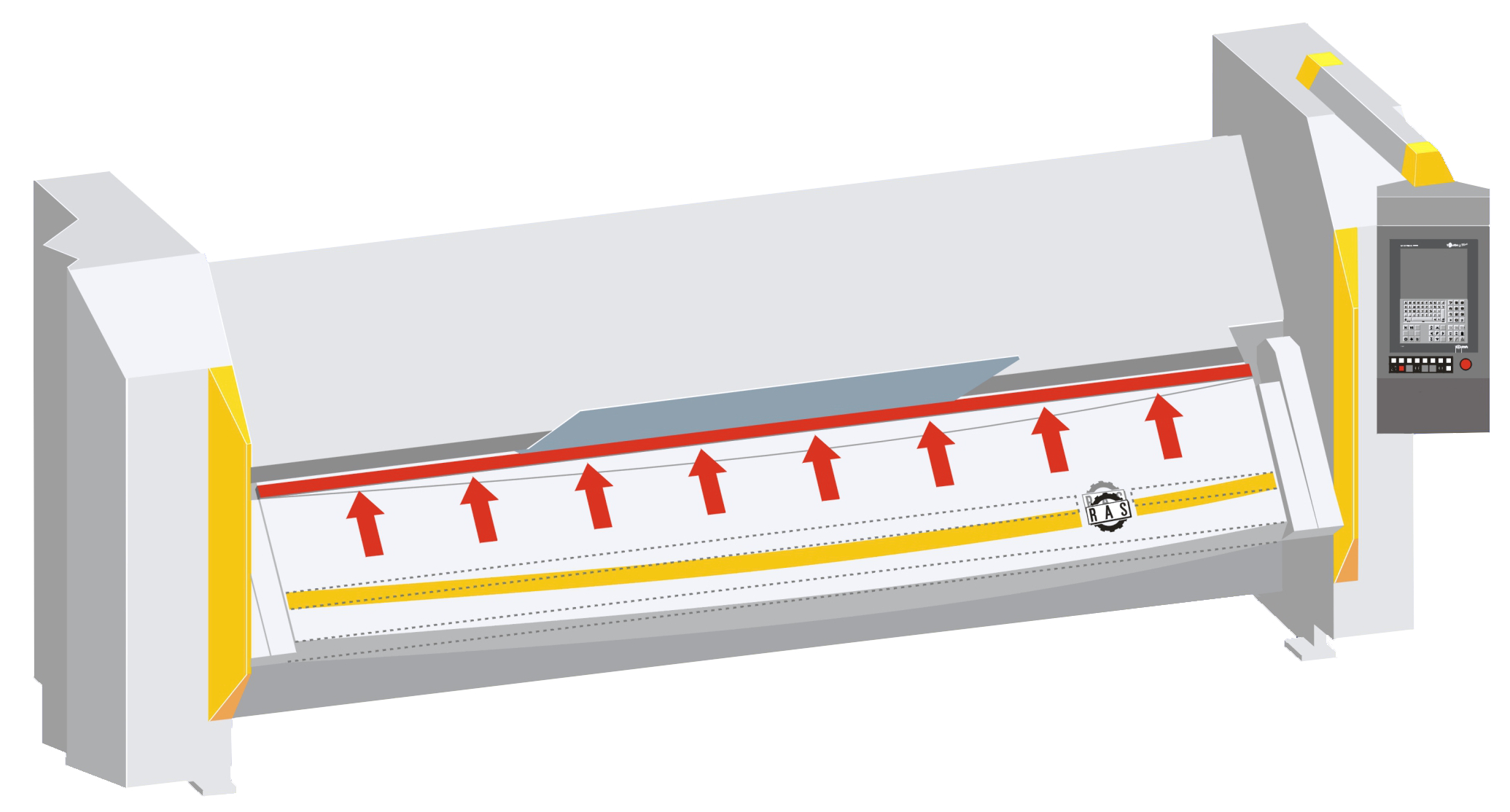

Folding beam

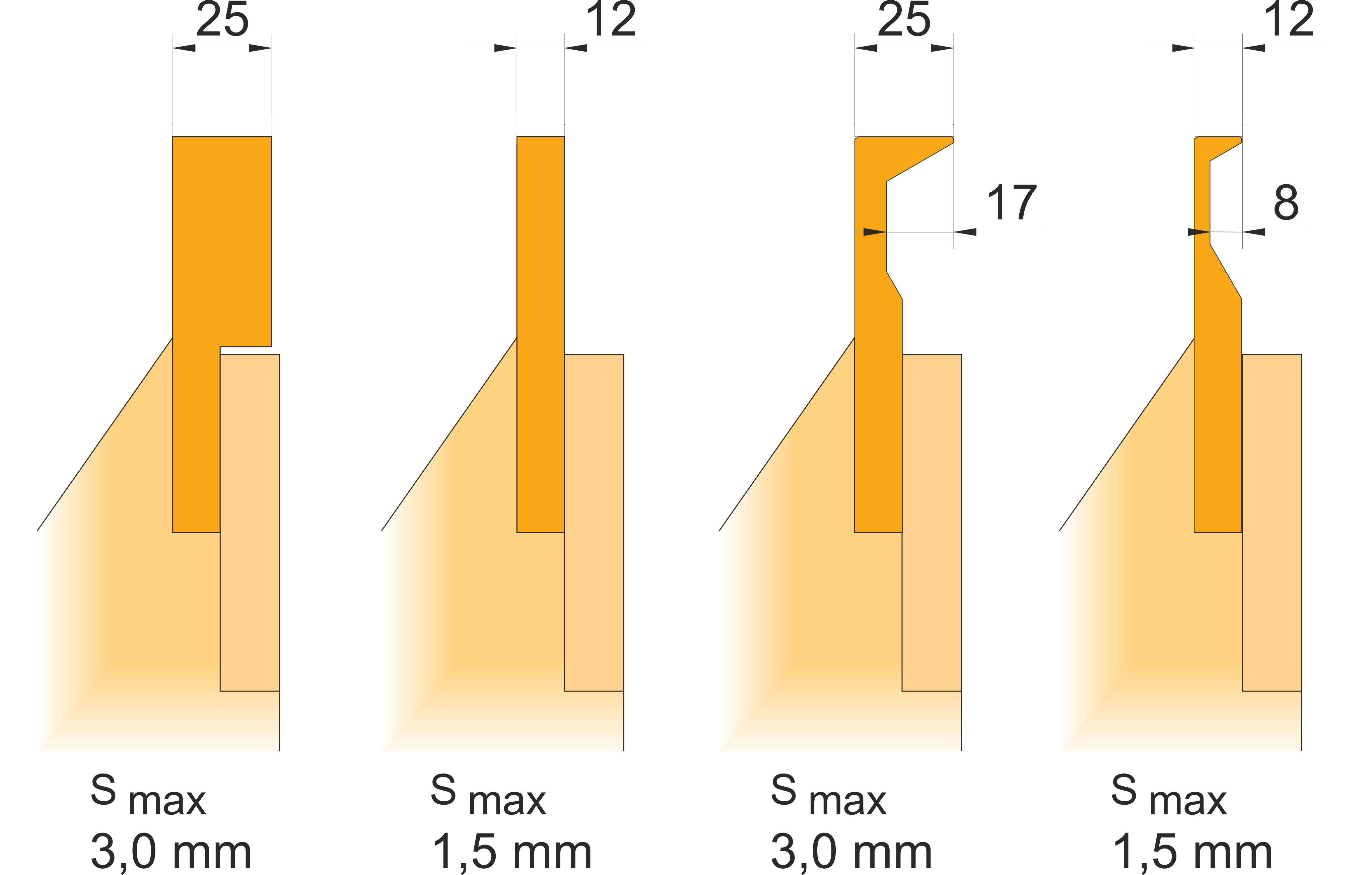

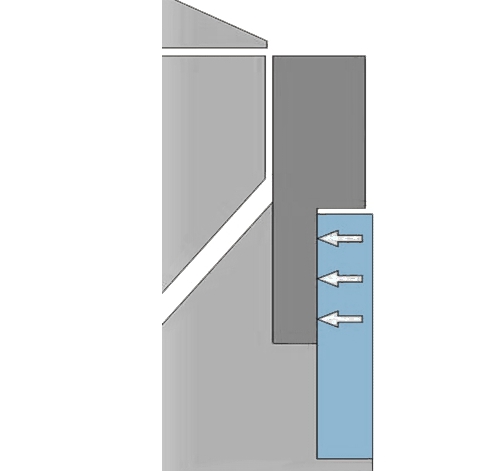

The folding beam is the most important component of folding machine. The intelligent crowning system automatically compensates for any folding beam deflection, caused by the bending forces. The FLEXIbend achieves straight bends on thin or thick sheets, all types of material, long or short flanges, bending in the machine center or on the side. The automatic sheet thickness and bend radius adjustment increases productivity and flexibility!

- Fast movement: short production time

- Deep folding beam: excellent bend results

- Automatic adjustment to sheet thickness and bend radius

- Clamps the segmented tools automatically

- Display shows the folding beam and lower beam position

- Simple and error-free machine calibration

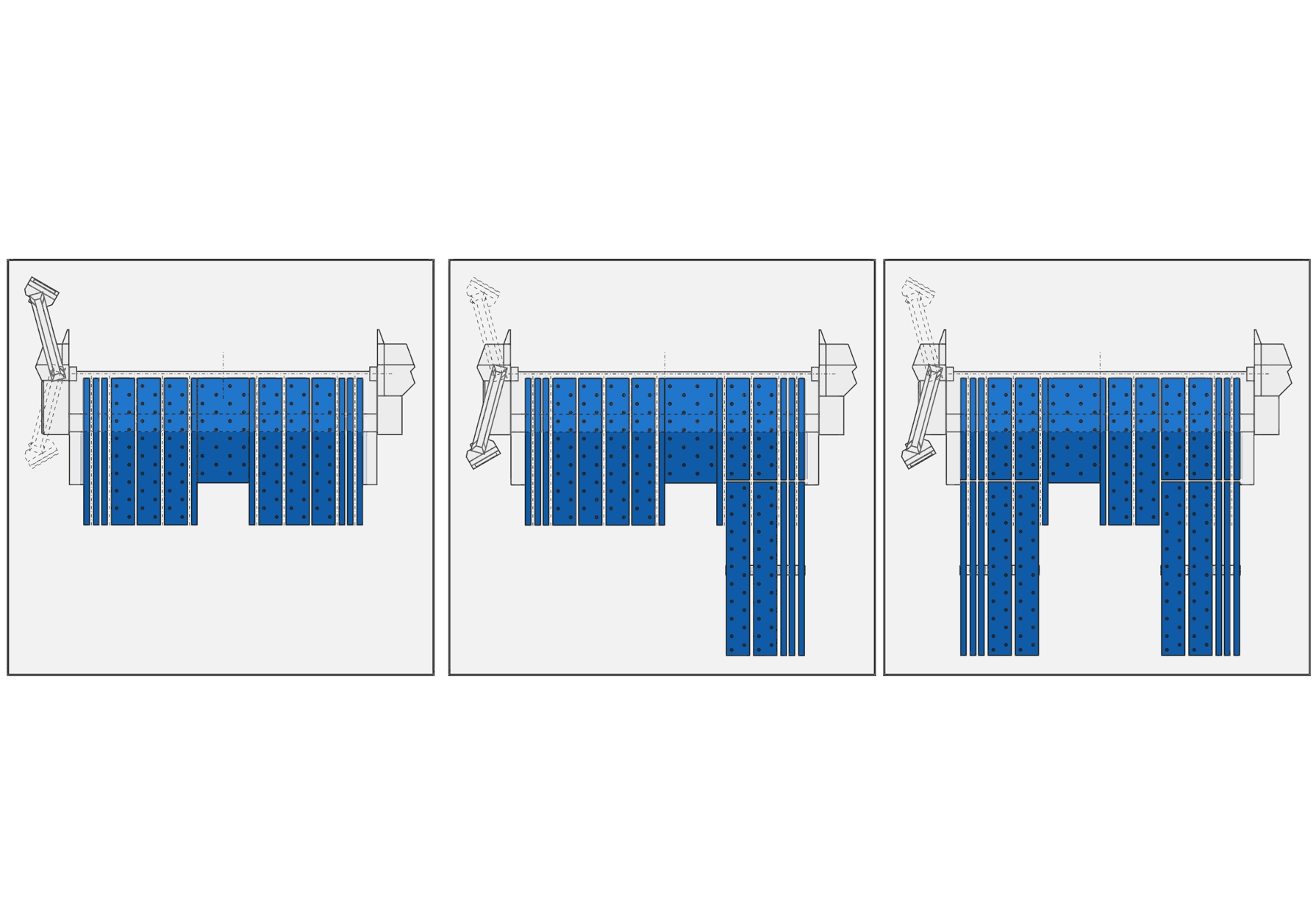

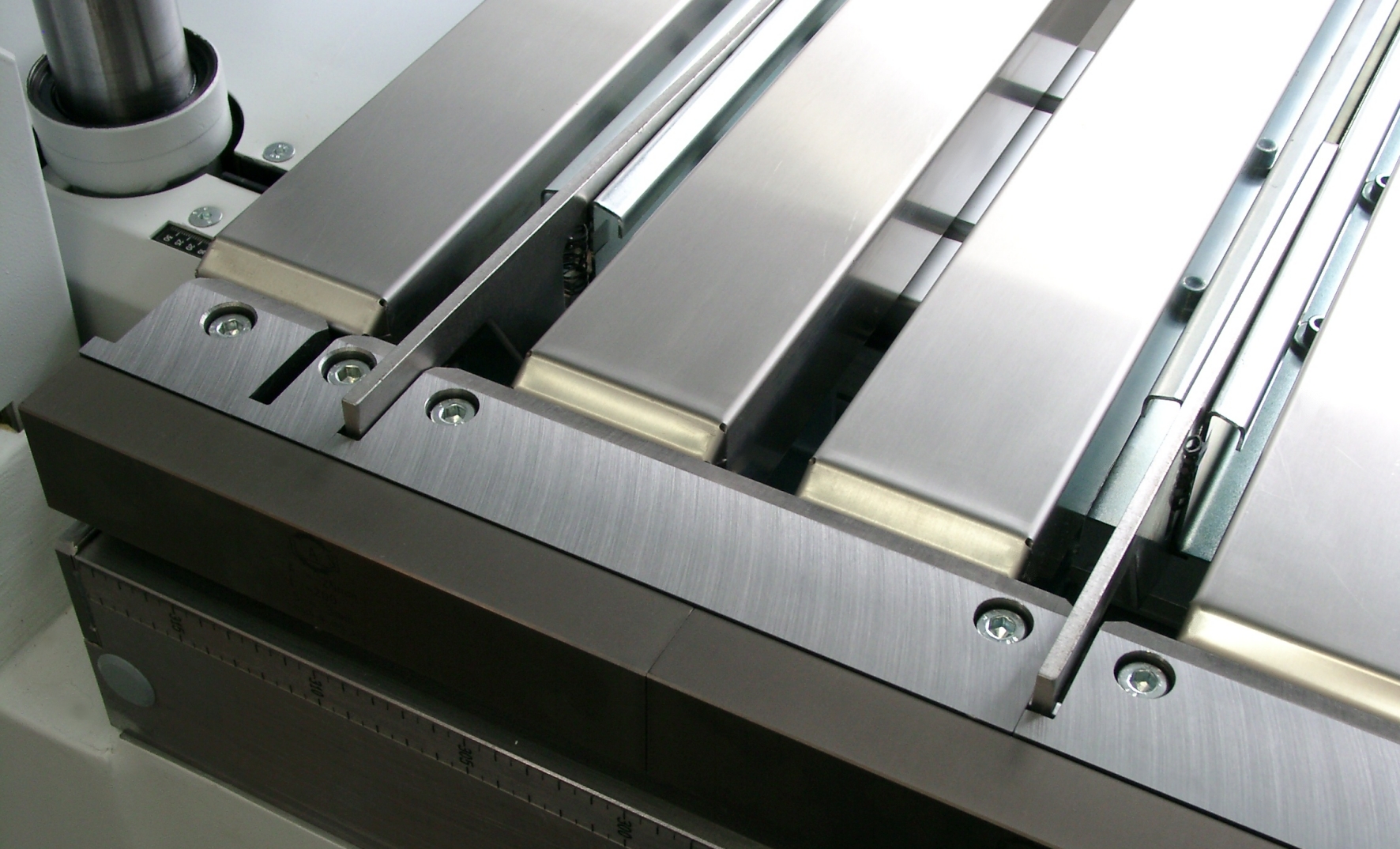

Sheet support and gauging system

This combined gauging and sheet support system holds the weight of the panel, positioning it exactly and makes part rotation simple and productive. The stop fingers position the part for each bend. All fingers disappear automatically when the operator wants to rotate the workpiece. For large parts, the rectangular gauging system can be extended to a J- or U-shape table.

- Working with repeating accuracy

- No 2nd operator (50% cost saving)

- No marking (30% time saving)

- Supports the weight of the part

- Adaptable to job assignment and space conditions

- Squaring arm for narrow and long parts

- Ball casters in sheet support panels (easy handling)

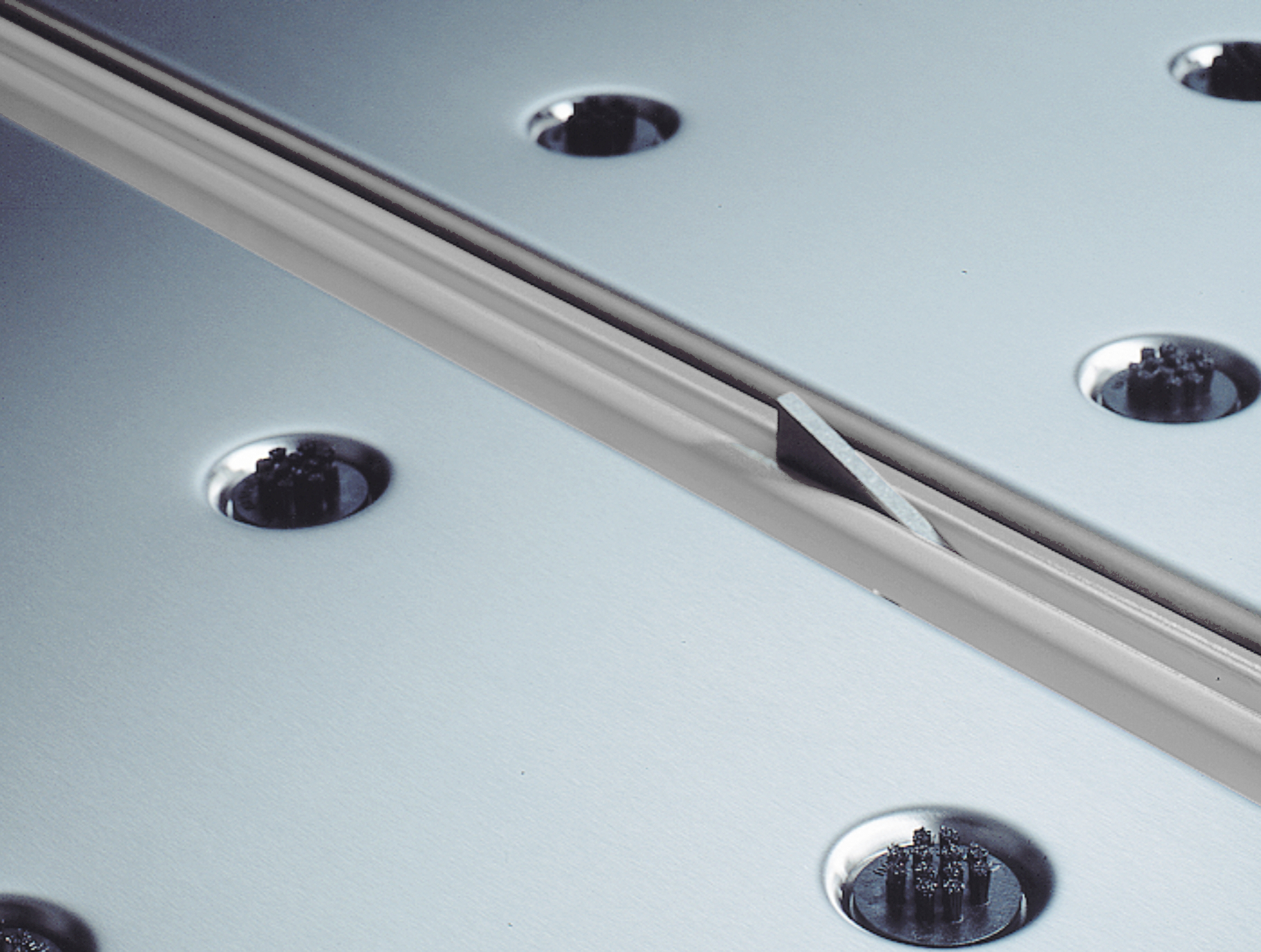

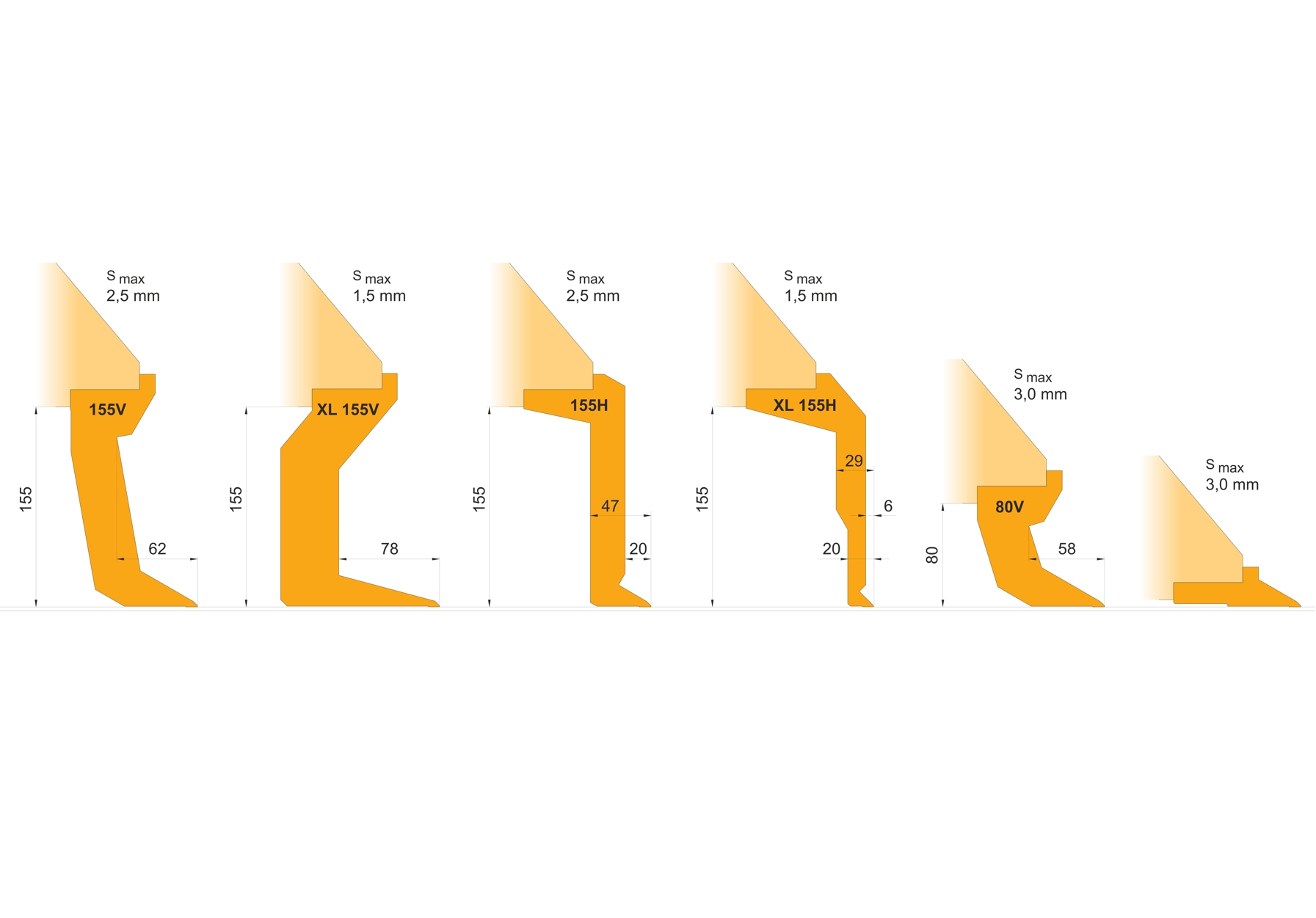

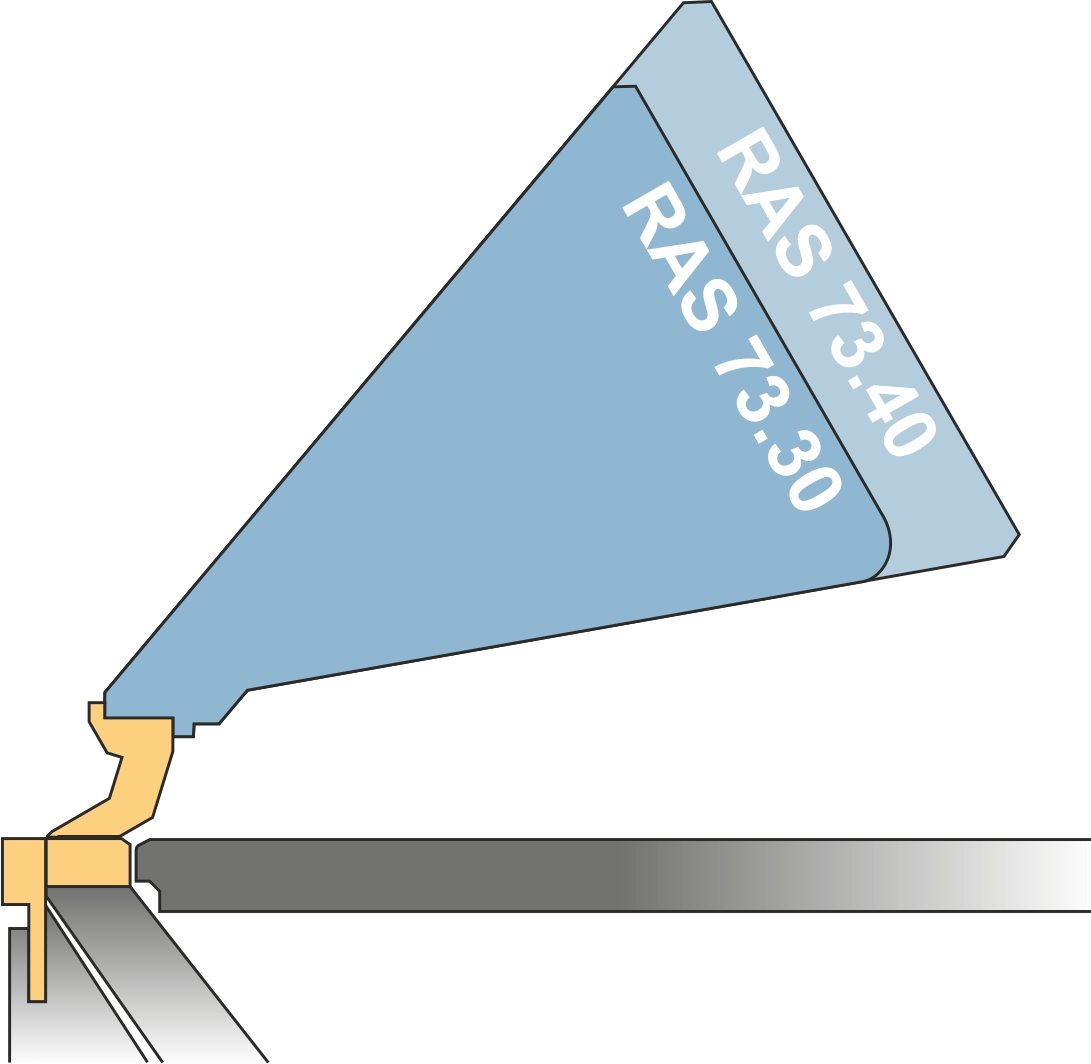

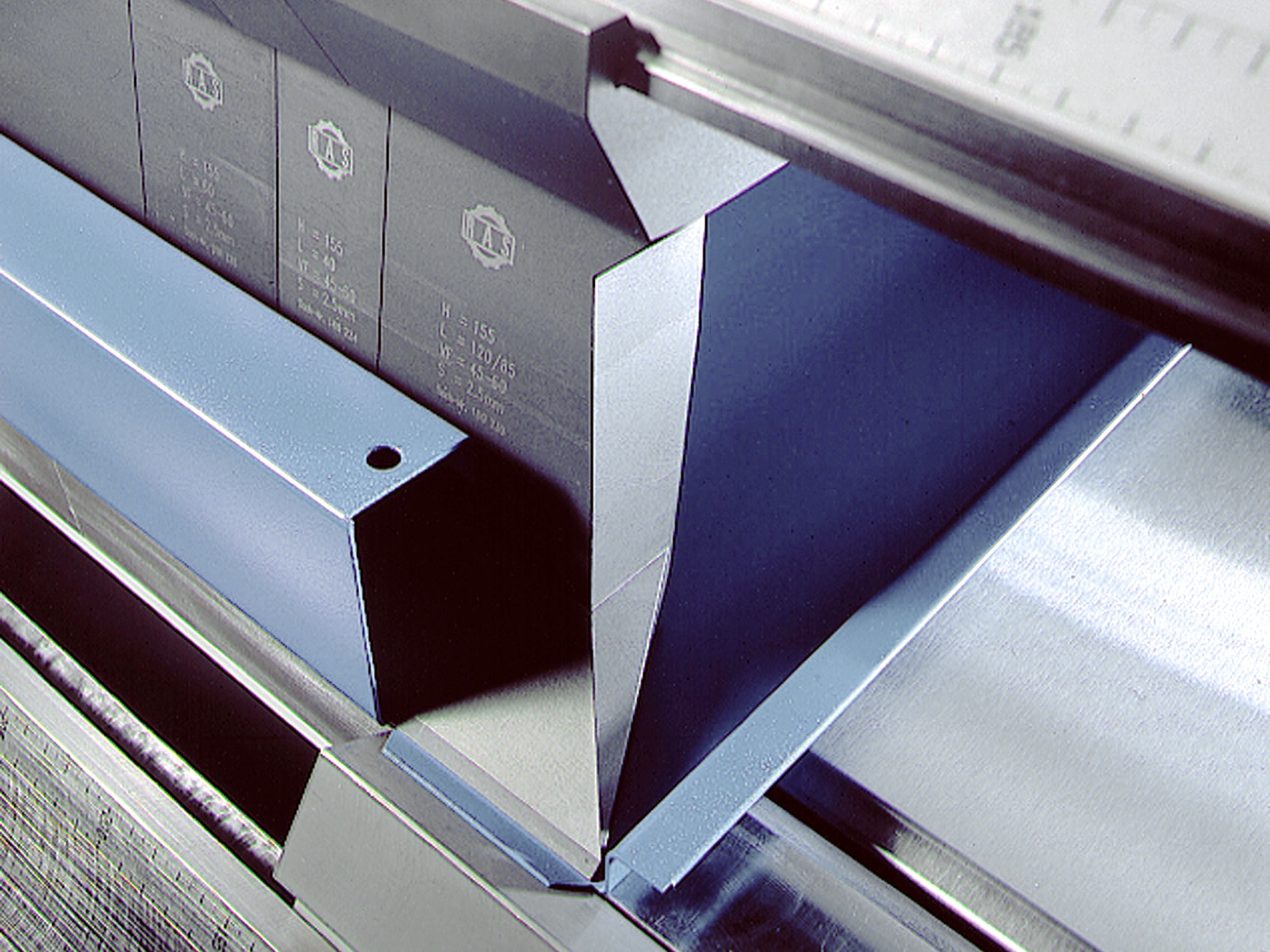

Tooling system

The high-strength and precision-ground upper beam tools are automatically clamped in the tool seat. No other tool system offers so much free space for all imaginable folding geometries. Handy tool segments of maximum make tool setups extremely simple.

- Large free spaces for flexible part designs

- Radius tools and special shapes on request

- Short set-up times: handy tools and automatic tool clamping

- Individually manufactured precision tools (retrofitable)

- Folding beam tool widths suitable for thickness and Z-bends

- Quick tool cahnges due to automatic tool clamping

- Incline folding beam tool for internal bends (windows, louvers)

- Segmented lower beam tools for reverse flanges

- Finger pockets in lower beam tools for small gauging dimensions

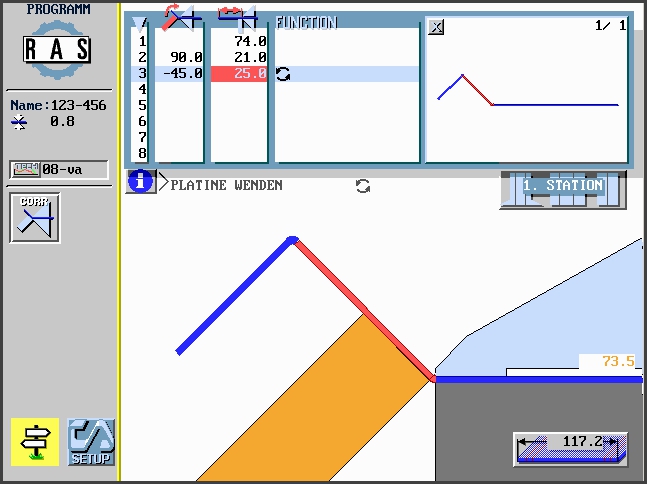

Touch&More control

Use your finger to draw the part with flanges and angles on the screen of the Touch&More control. The software shows the part together with tools and machine components in the later working situation.

- Control panel on an arm

- Drawing of the part with the finger

- For most workpieces automatic part programming

- Technology tables (angle correction/unfolded length)

- Programm, part and actual bending step are shown at a time

- Program library

- Operator guidance (text and symbols)

- Speed Optimizer for 15% less cylce times

- EasyGo program for occasional operators

![[Translate to english:] Automatische auf Blechdicke und Biegeradius [Translate to english:] Automatische auf Blechdicke und Biegeradius](/fileadmin/user_upload/BW-UW-Verstellung_2009.jpg)